Driver for synchronous control of multiple motors

A technology of synchronous control and drive, applied in the direction of speed/torque control of multiple motors, can solve the problems of increasing the volume and weight of the system, and achieve the effect of reducing weight and volume, avoiding relative complexity, and reducing weight and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

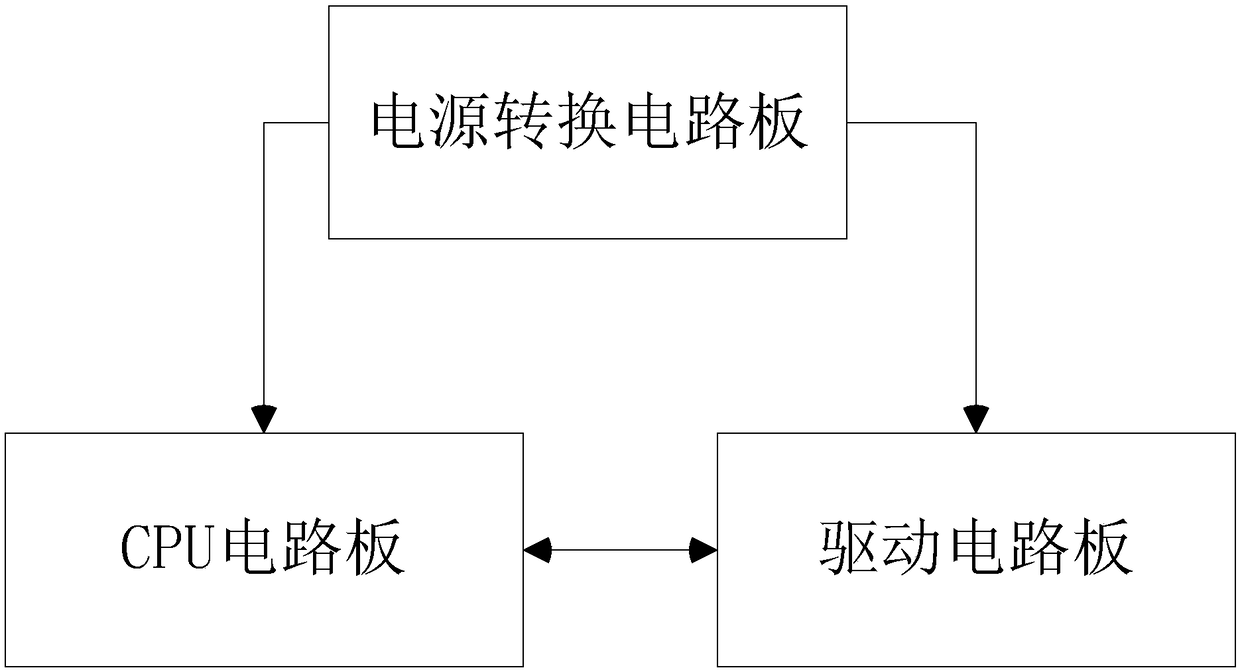

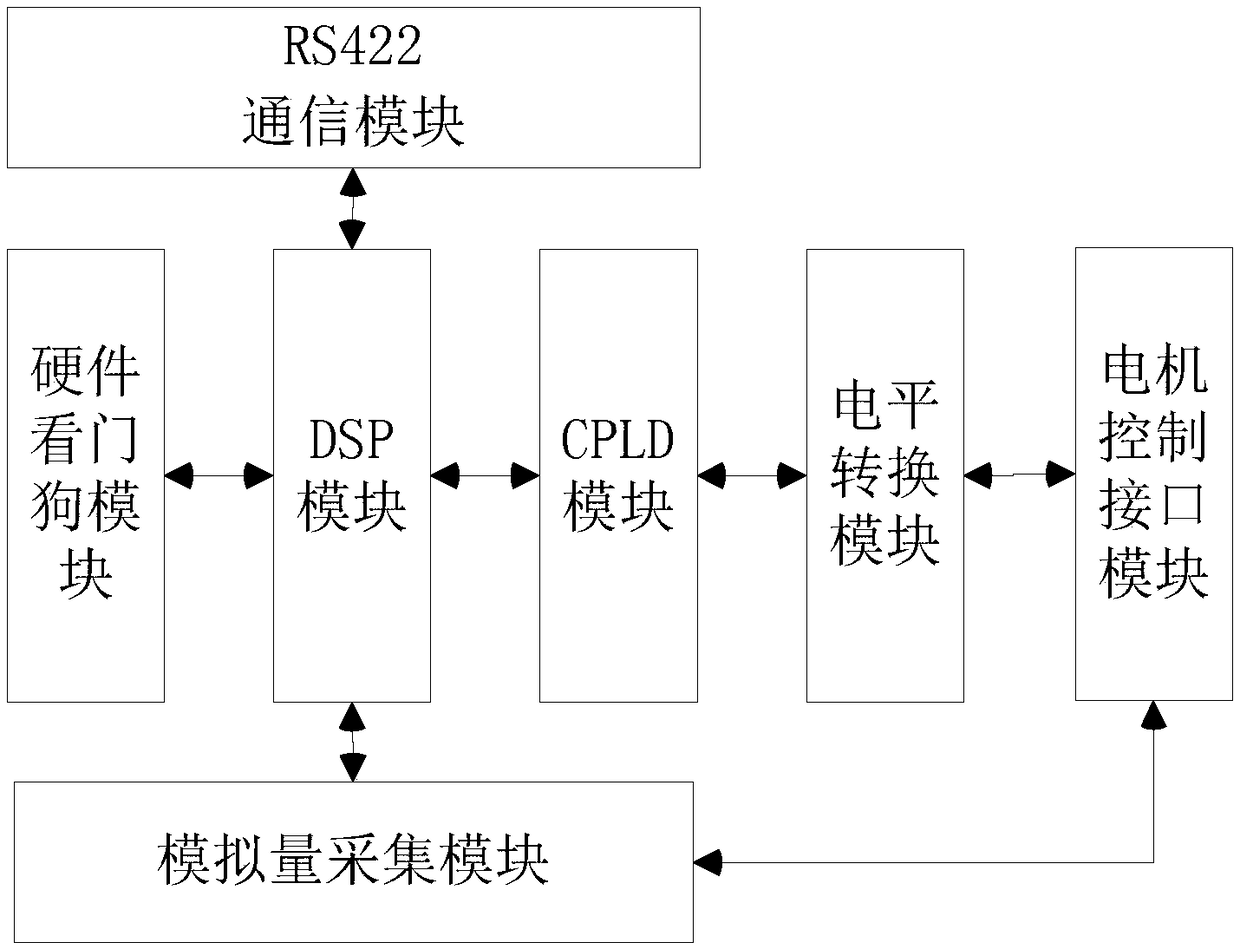

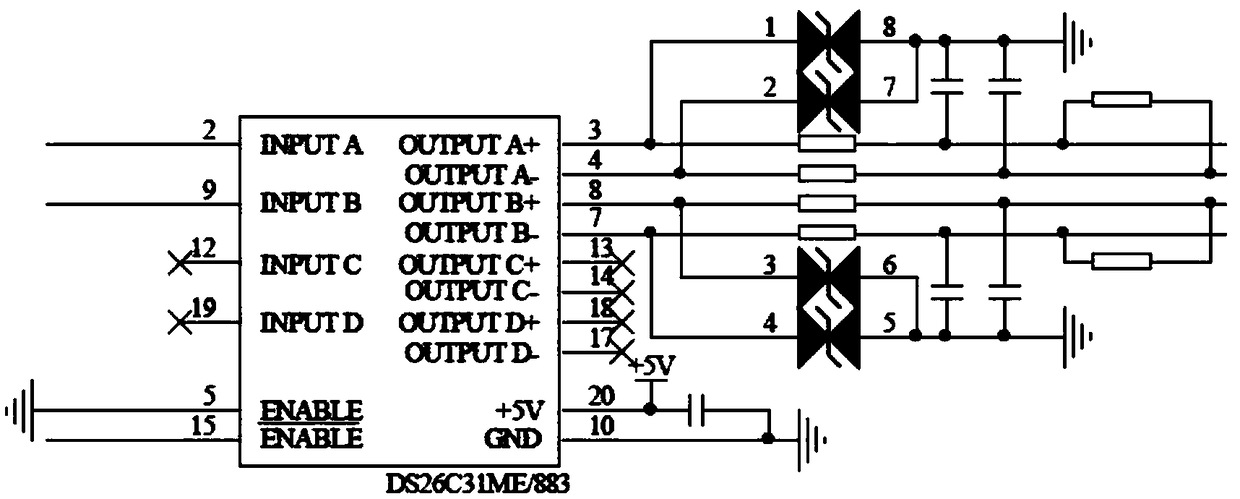

[0019] see figure 1 , figure 2 . In the embodiment described below, a driver for synchronously controlling multiple motors includes: a power conversion circuit board, a CPU circuit board, and a drive circuit board. The CPU circuit board is composed of a DSP module, a CPLD module, an RS422 communication module, an analog quantity acquisition Module, motor control interface module, hardware watchdog module, level conversion module. The power conversion circuit board, the CPU circuit board and the driving circuit board are connected through flat connecting wires. The power conversion circuit board, the CPU circuit board and the driving circuit board form a driver system for synchronously controlling multi-channel motors. The power conversion circuit board provides voltage for the CPU circuit board and the driving circuit board. Motor position, current, speed and other information, the CPU circuit board provides the drive circuit board with four working modes: analog input mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com