Selenium fertilizer and cultivation method for selenium-enriched millet

A cultivation method and a selenium-enriching technology, applied in grain cultivation, fertilization methods, organic fertilizers, etc., can solve the problems of insignificant selenium absorption, unstable selenium content performance, and substandard levels, so as to avoid high selenium and low selenium, The effect of improving selenium deficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A selenium fertilizer, comprising sodium selenite, selenium-enriched wastewater, and fulvic acid, wherein, fulvic acid: selenium element: water = (2-3): (0.19-0.46): 1. During application, the selenium fertilizer and water are applied in a ratio of 1:99 parts by weight.

Embodiment 2

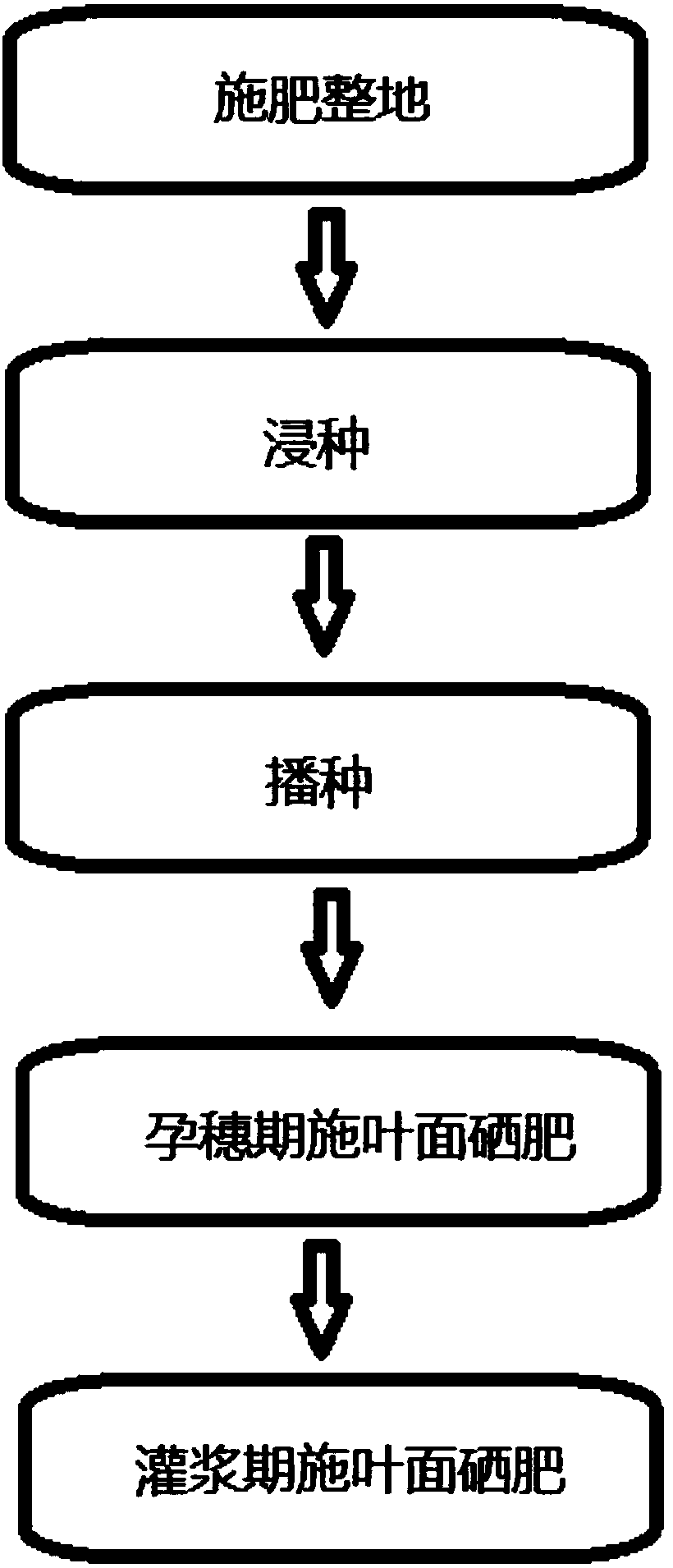

[0044]Fertilization and land preparation, the fertilization and land preparation include applying base fertilizer, rotary tillage, and compaction after the harvest of previous crops

[0045] For sowing, use sodium selenite or potassium selenite to soak the seeds for 24 hours before sowing. The sowing is carried out in the middle and late May. It is drill sowing, and the sowing rate is 9kg / hm 2 . ;

[0046] Application of exogenous selenium: Spray selenium fertilizer on the leaves at the booting stage and filling stage respectively, among which,

[0047] The selenium fertilizer includes a selenium source and fulvic acid water, the selenium source includes sodium selenite and selenium-enriched wastewater, and the content of selenium in the selenium source is 40-50g / hm 2 , the mass ratio of fulvic acid, selenium, and water is 2.5:0.39:100, and the selenium content in the obtained millet is shown in Table 1.

Embodiment 3

[0049] Fertilization and land preparation, the fertilization and land preparation include applying base fertilizer, rotary tillage, and compaction after the harvest of previous crops

[0050] Sowing, the sowing is carried out in the middle and late May, and it is drill sowing, and the sowing rate is 6kg / hm 2 . ;

[0051] Application of exogenous selenium: Spray selenium fertilizer on the leaves at the booting stage and filling stage, among which,

[0052] The selenium fertilizer includes a selenium source and fulvic acid water, the selenium source includes sodium selenite and selenium-enriched wastewater, and the content of selenium in the selenium source is 40-50g / hm 2 , the mass ratio of fulvic acid, selenium, and water is 3:0.19:100, and the selenium content in the obtained millet is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com