Improved tobacco preparation device

A preparation device and improved technology, applied in the field of improved tobacco preparation devices, can solve the problems affecting production efficiency, complex structure, single crushing operation, etc., and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

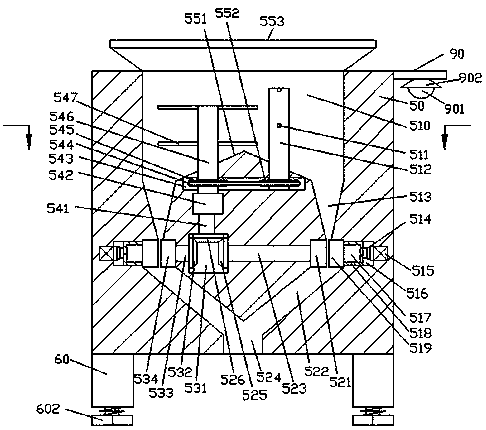

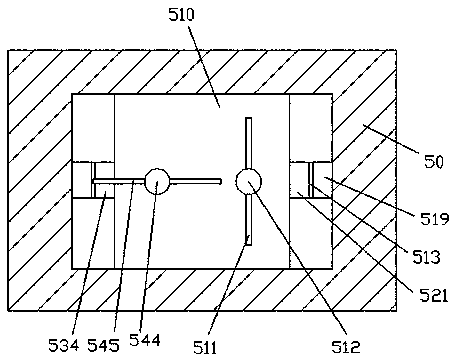

[0016] Combine below Figure 1-3 The present invention will be described in detail.

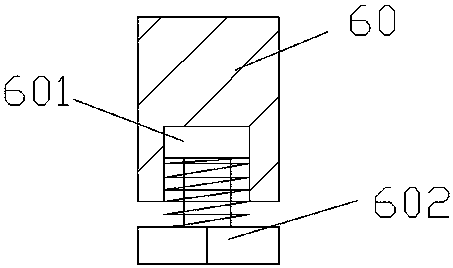

[0017] refer to Figure 1-3 , an improved tobacco preparation device according to an embodiment of the present invention, comprising a housing box 50 fixedly arranged on the bottom frame 60, a threaded hole 601 is provided in the corner bottom of the bottom frame 60, and the threaded hole 601 fits A threaded pad angle 602 is installed, through which the threaded pad angle 602 can be adjusted when the ground is uneven, thereby improving the stability of the underframe 60 when supported, and the top end surface of the storage box 50 is provided with a storage box 510, the left and right sides of the inner bottom wall of the storage box 510 communicate with each other to provide a first discharge cavity 513, and the inner wall of the storage box 50 between the left and right sides of the first discharge cavity 513 is provided with a second discharge cavity extending left and right. A steering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com