Automobile part cleaning device

A technology for auto parts and cleaning devices, which is applied to cleaning methods and appliances, cleaning methods using liquids, local agitation dryers, etc. It can solve the problems of affecting the construction period, low cleaning efficiency, and long drying time of auto parts, and achieves Ease of dehydration processing and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Further detailed explanation through specific implementation mode below:

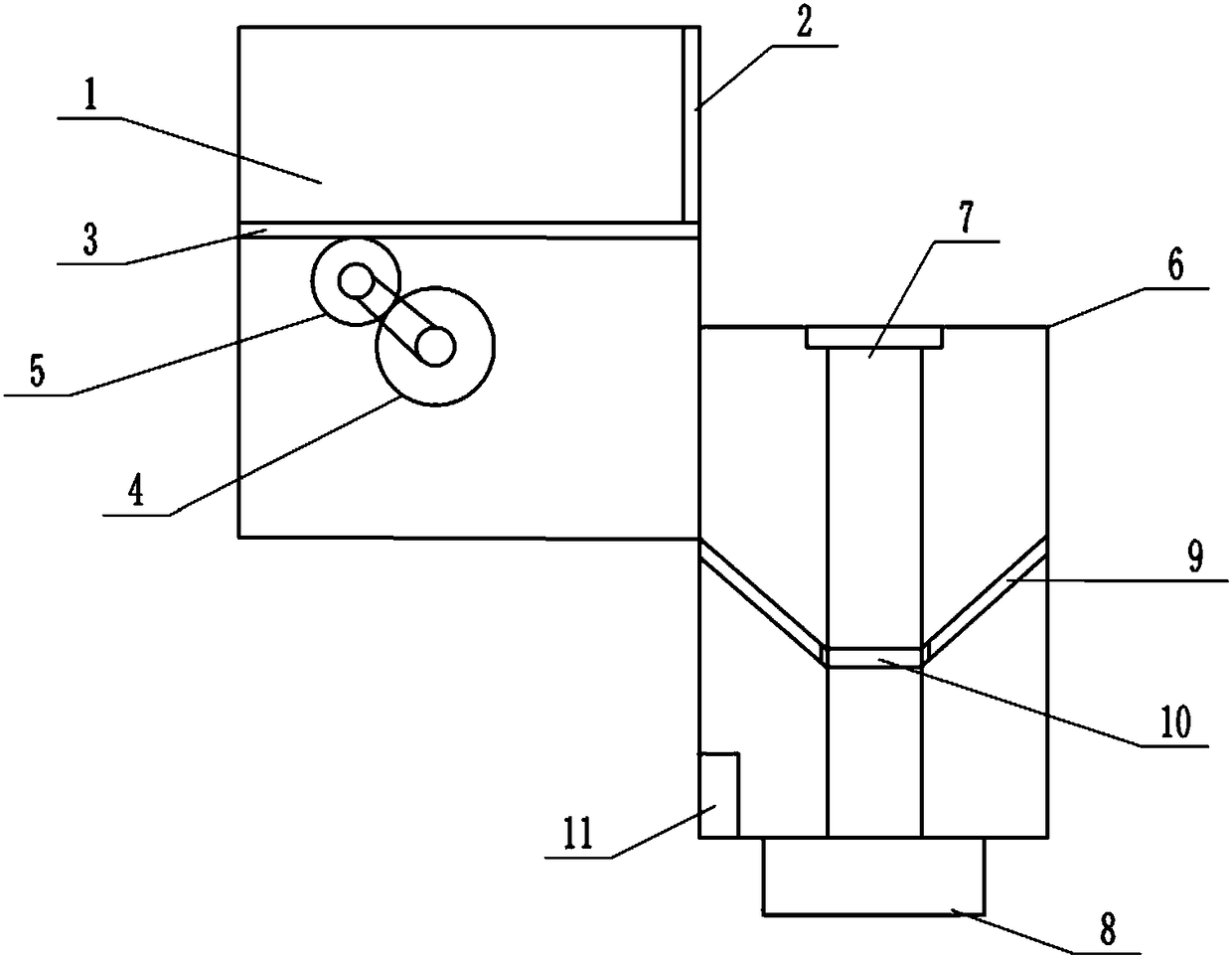

[0012] The reference signs in the drawings of the description include: cleaning tank 1, discharge baffle plate 2, diaphragm 3, driving gear 4, driven gear 5, dehydration tank 6, screw rod 7, motor 8, filter screen 9, threaded ring 10, Outlet valve 11.

[0013] The embodiment is basically as attached figure 1 Shown:

[0014] A cleaning device for auto parts, comprising a cleaning tank 1 and a dehydration tank 6, the bottom of the cleaning tank 1 is provided with a driving gear 4 driven by external driving equipment, the edge of the driving gear 4 is meshed with a driven gear 5, the driving gear 4 and the driven gear The rotating shaft of 5 is fixedly connected by a conveyor belt. The inner wall of the cleaning tank 1 is provided with a plastic diaphragm 3 above the driving gear 4. The upper surface of the diaphragm 3 is provided with several protrusions; the right side wall of the cleaning tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com