Copper seal automatic filling machine

An automatic filling machine, copper water stop technology, applied in water conservancy projects, marine engineering, construction and other directions, can solve the problems of slow speed, difficult filling, difficult to ensure filling quality, etc., to achieve fast filling speed, high construction efficiency, and cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

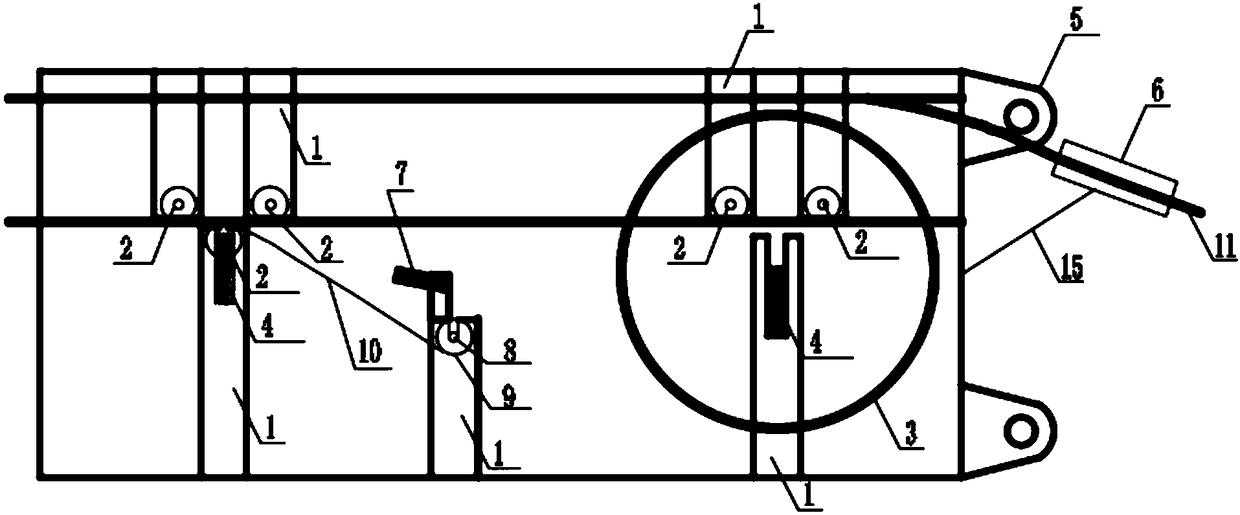

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

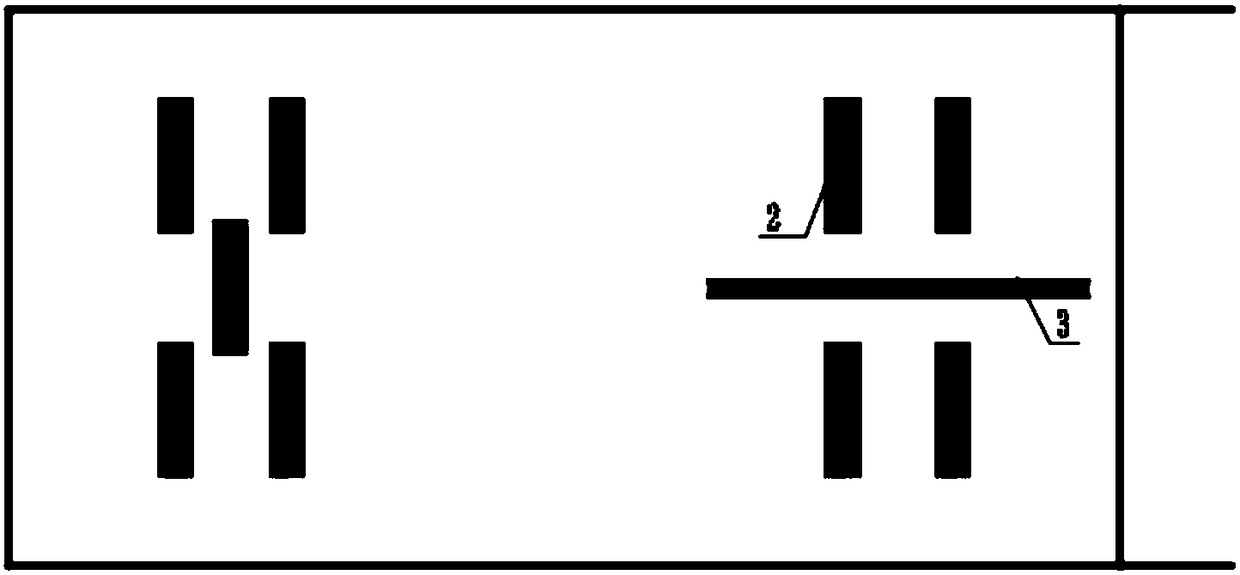

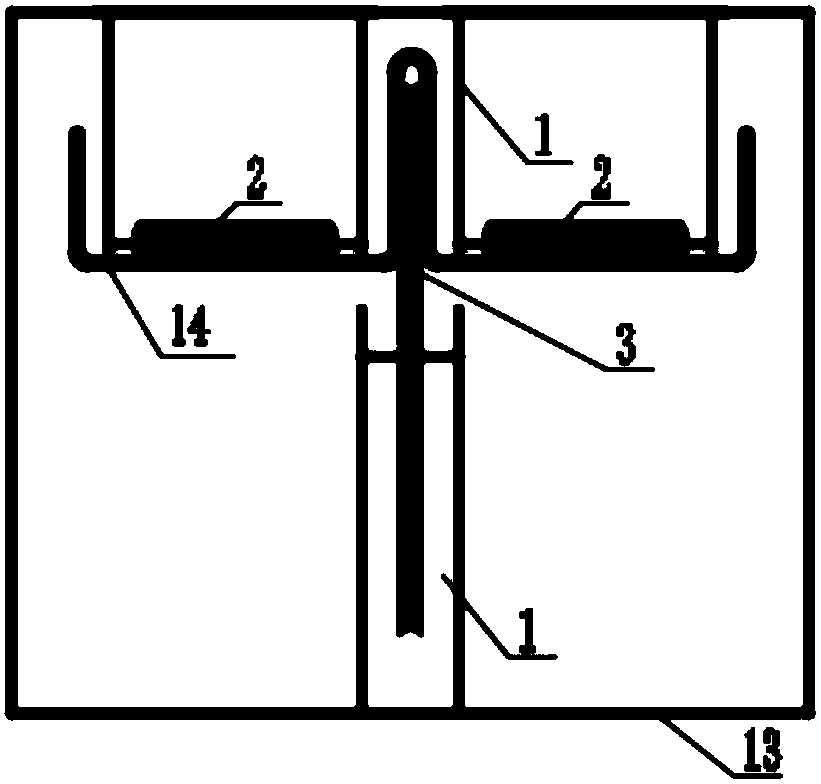

[0023] A copper water stop automatic filling machine according to the present invention has the following structure: an outer frame 13 is provided, and along the moving direction of the copper water stop 14 relative to the outer frame 13, the outer frame 13 is respectively front, middle and rear; At the front of the outer frame 13, a number of rollers 2 are connected through the bracket 1 above the outer frame 13, where the lowermost edge of the roller 2 can touch the horizontal section of the copper water seal 14; the lower part of the outer frame 13 is also fixed with a bracket 1, here The bracket 1 is connected to the runner 3 through a high-strength spring 4, the uppermost edge of the runner 3 is close to the nose of the copper water stop 14, and the runner 3 is used for compacting the rubber rod 11; in the middle of the outer fram...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap