Capacity-tube-capacity type gas-flow pulsation attenuator of compressor

An air pulsation and compressor technology, applied in the direction of machine/engine, mechanical equipment, variable displacement pump components, etc., can solve the problem of increasing the resistance loss of the capacity-tube-capacity air pulsation attenuator, reducing the economy and reliability of the compressor. performance, poor airflow pulsation attenuation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below in conjunction with accompanying drawing:

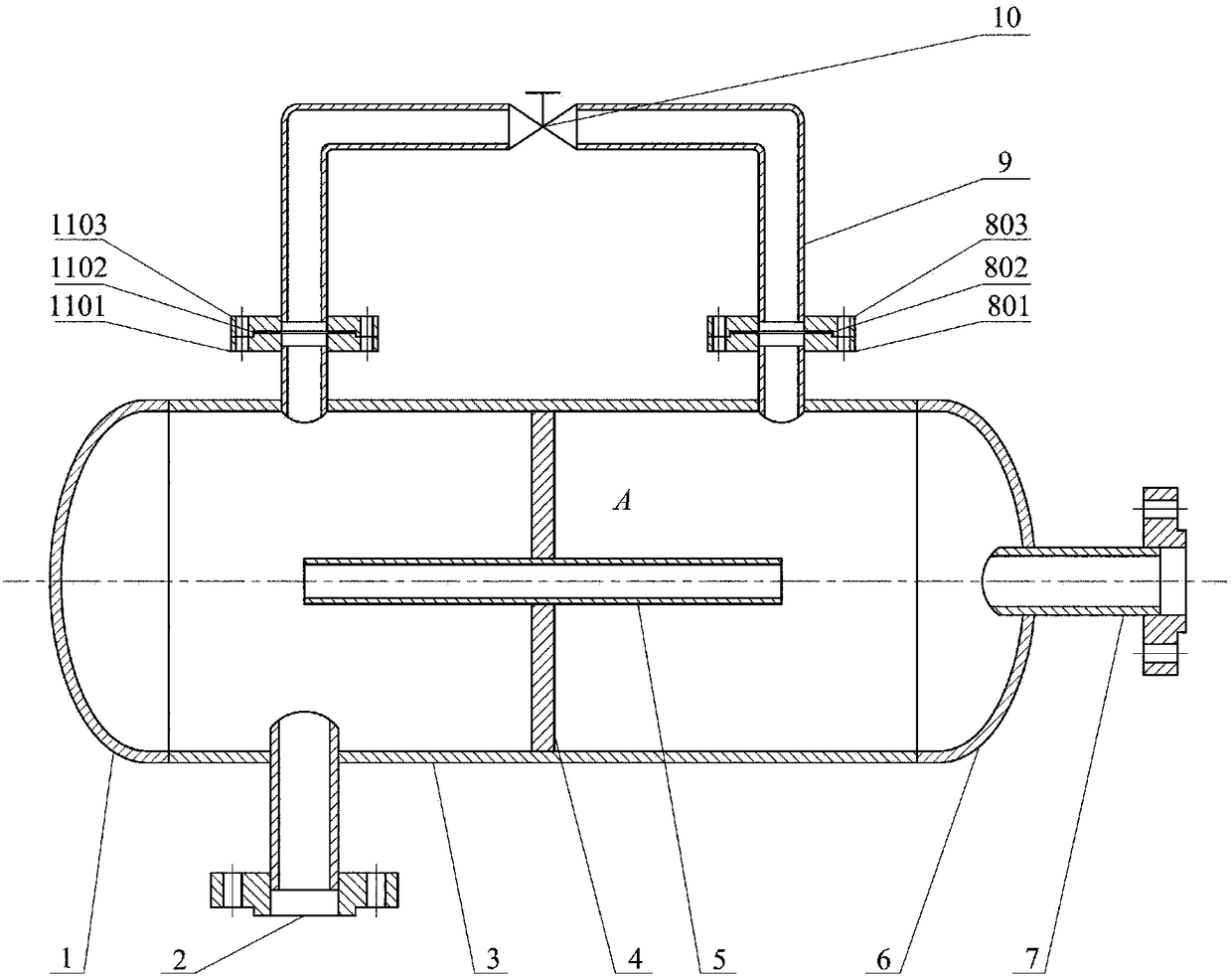

[0020] see picture figure 1 As shown, the compressor capacity-tube-capacity air flow pulsation attenuator proposed by the present invention includes a container shell 3, a head 1, a head 6, an inner throat 5, an outer throat 9 and a circular The partition 4, wherein the container shell 3 is a cavity with two sections of open cylindrical structure, the two ends of the container shell 3 are respectively connected with the left head 1 and the right head 6, the container shell 3 and the left head 1. The right sealing head 6 together forms the container chamber A. The inner wall surface of the container shell 3 is fixed with a coaxial circular partition 4, and a through hole is opened on the circular partition 4, and an inserting throat 5 is coaxially and tightly fixed on the through hole, and the connection method can be threaded connection or welding .

[0021] The out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com