Method for detecting arc surface error of aircraft cabin door

An error detection and arc surface technology, which is applied in the field of digital detection and can solve the problems that the measurement results depend on the arc length of small arcs and the degree of automation is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

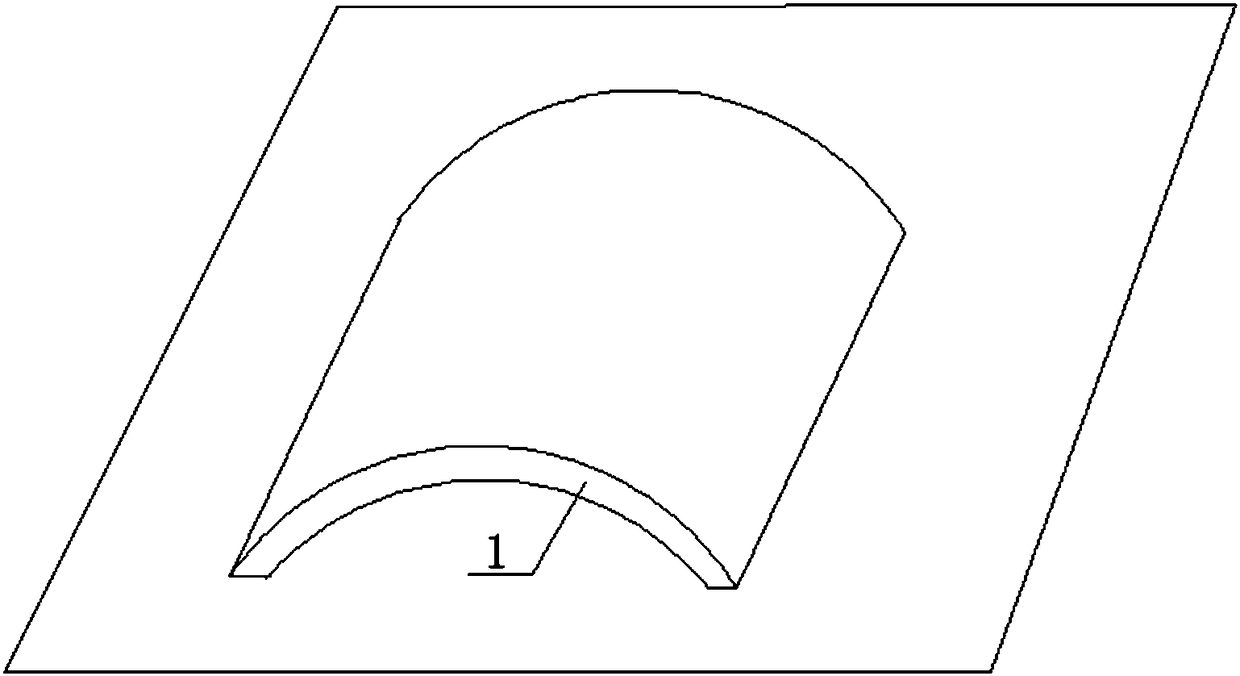

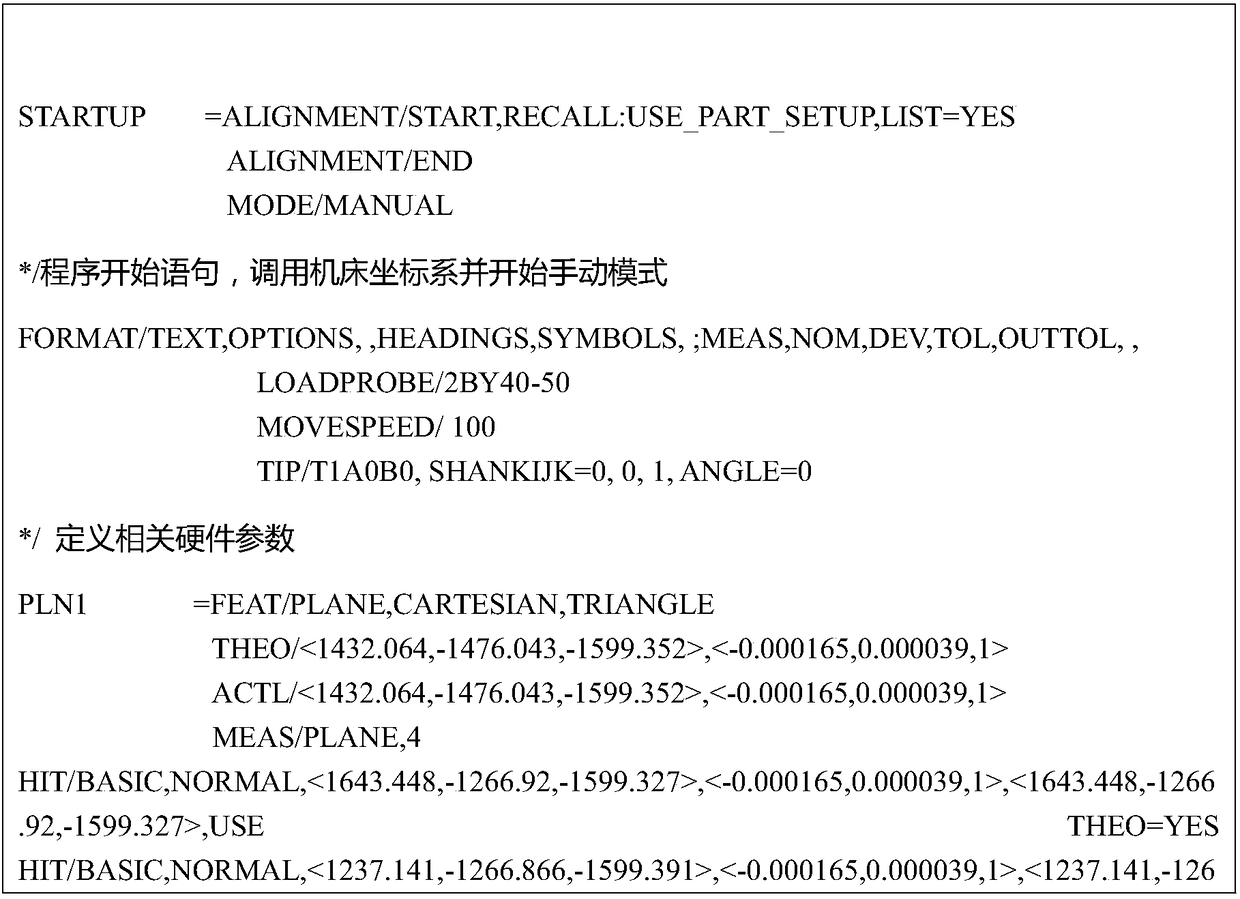

[0024] According to attached Figure 1-2 , a method for detecting an error of an arc surface of an aircraft cabin, is characterized in that it is measured in layers according to the arc section, and the steps are as follows:

[0025] (1) Place the large-radius and small-arc parts on the three-coordinate measuring machine platform for positioning;

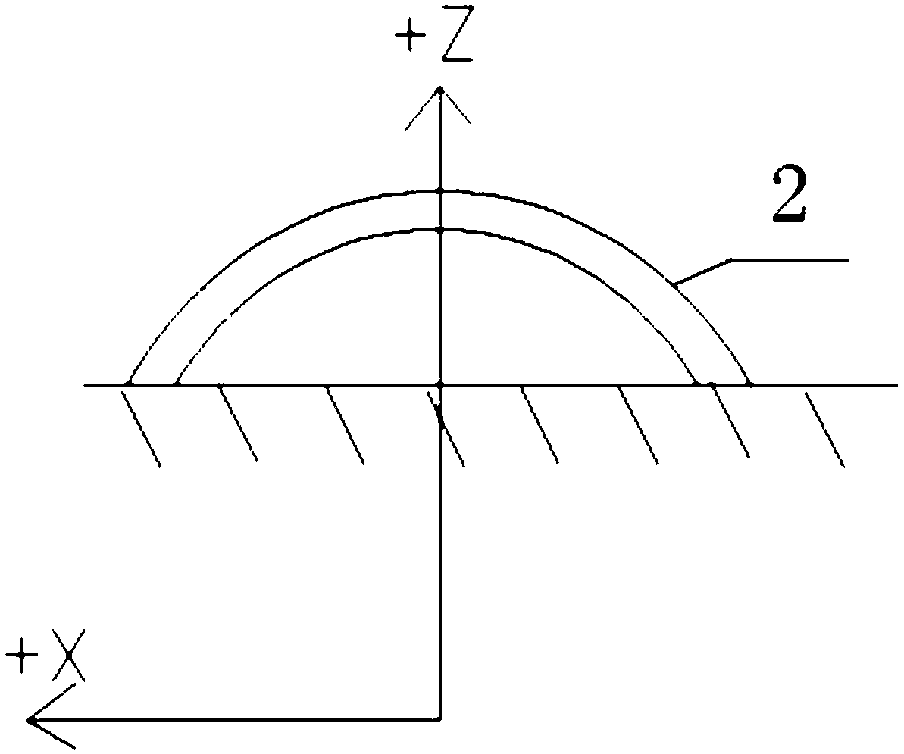

[0026] (2) The plane vector direction is defined as the Z-axis positive direction with the table top of the machine tool platform as the reference, and the plane is defined as the Z-direction zero plane;

[0027] (3) Measure three points on the end surface 1 of the product, and fit the three points into a plane. The vector direction of the plane is defined as the negative direction of the Y axis, and the plane is defined as the zero plane in the Y direction;

[0028] (4) A set of coordinate data is scanned near the highest point in the Z direction of the arc surface 2 of the part, and its range covers the highest point in the Z dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com