Vibration signal-based mechanical link looseness detection and early warning method

A vibration signal and mechanical technology, applied in the fields of diagnosis and failure monitoring of mechanical equipment, can solve problems such as frequency ambiguity, achieve timely maintenance or replacement, avoid major accidents, and achieve the effect of friendly human-machine interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for detecting and pre-warning mechanical link looseness based on vibration signals. By collecting the vibration signal of the vibration device of the mechanical link, the loose condition of the mechanical link is judged and the warning information is given.

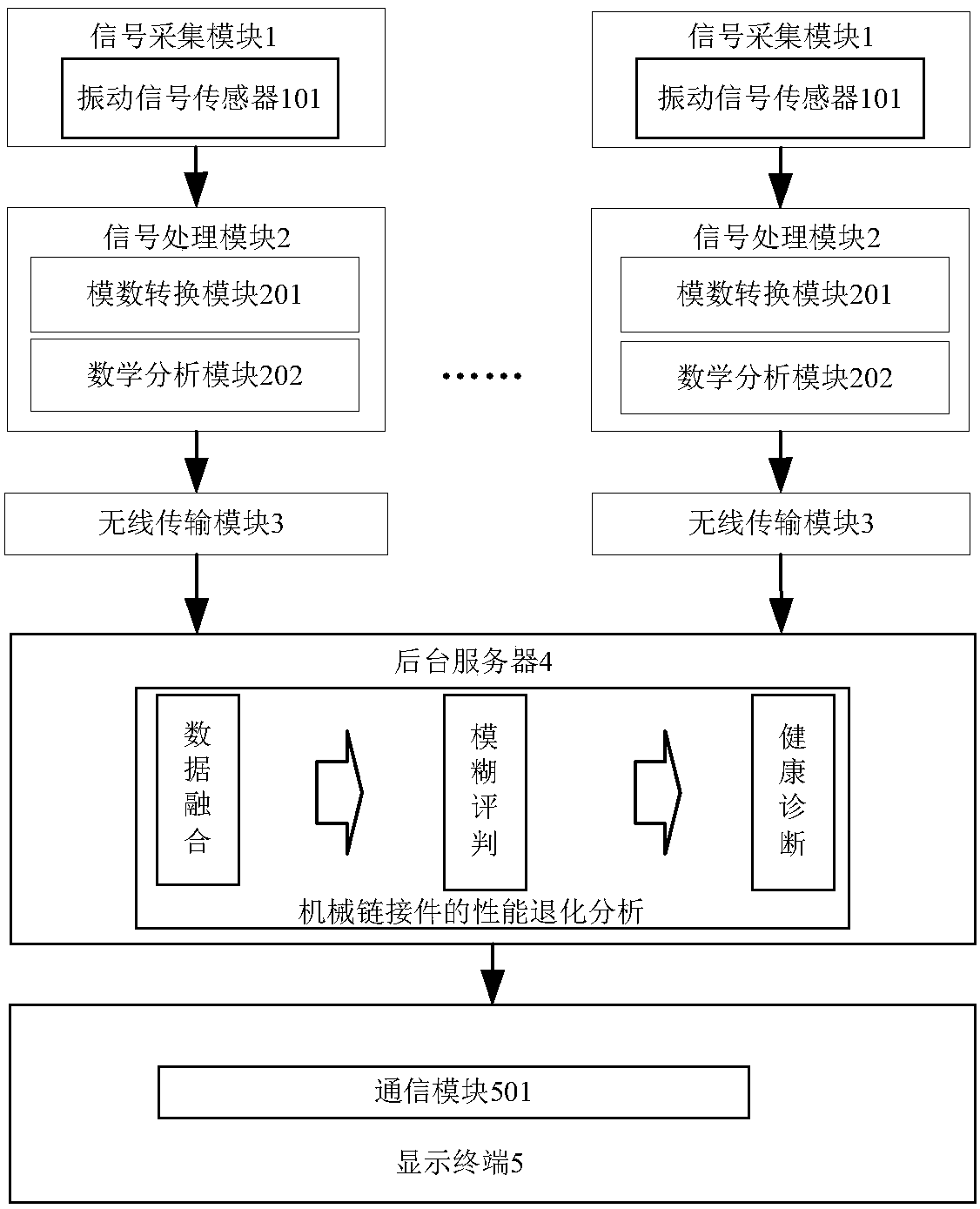

[0047] In this embodiment, as figure 1 As shown, the system for implementing the vibration signal-based mechanical link loosening detection and early warning method includes a signal acquisition module 1, a signal processing module 2, a wireless transmission module 3, a background server 4 and a display terminal 5. The signal acquisition module 1, The signal processing module 2, the wireless transmission module 3, the background server 4 and the display terminal 5 are connected in sequence. The wireless transmission module 3 is a GPRS module. The display terminal 5 is a desktop computer, and the display terminal 5 is provided with a communication module 501 for receiving the actual operating status and earl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com