Machine-soil acting force soil groove testing and detecting device and method thereof

A detection device and force technology, which is applied in the field of agricultural machinery, can solve the problems of low test accuracy of machine advance speed and inability to simulate the working conditions of paddy field soil, etc., and achieve the effect of compact device structure and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the technical features in each embodiment can be combined with each other without conflict, which does not constitute a limitation.

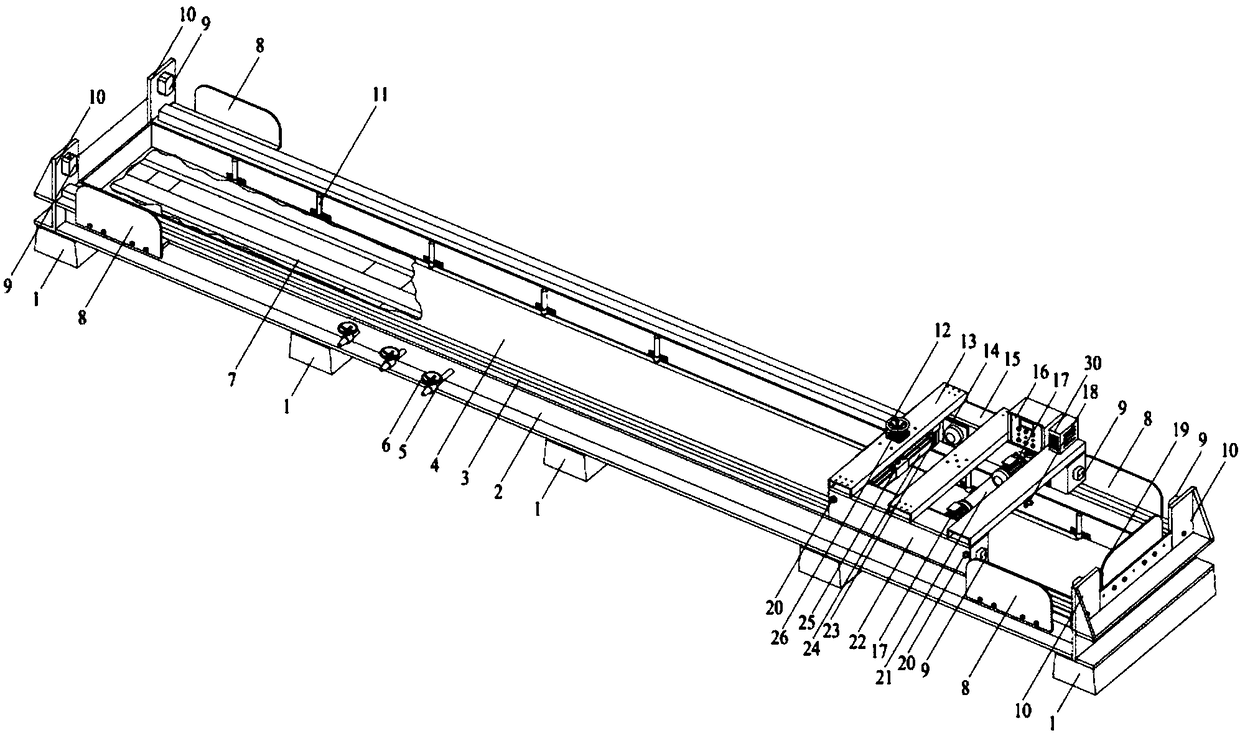

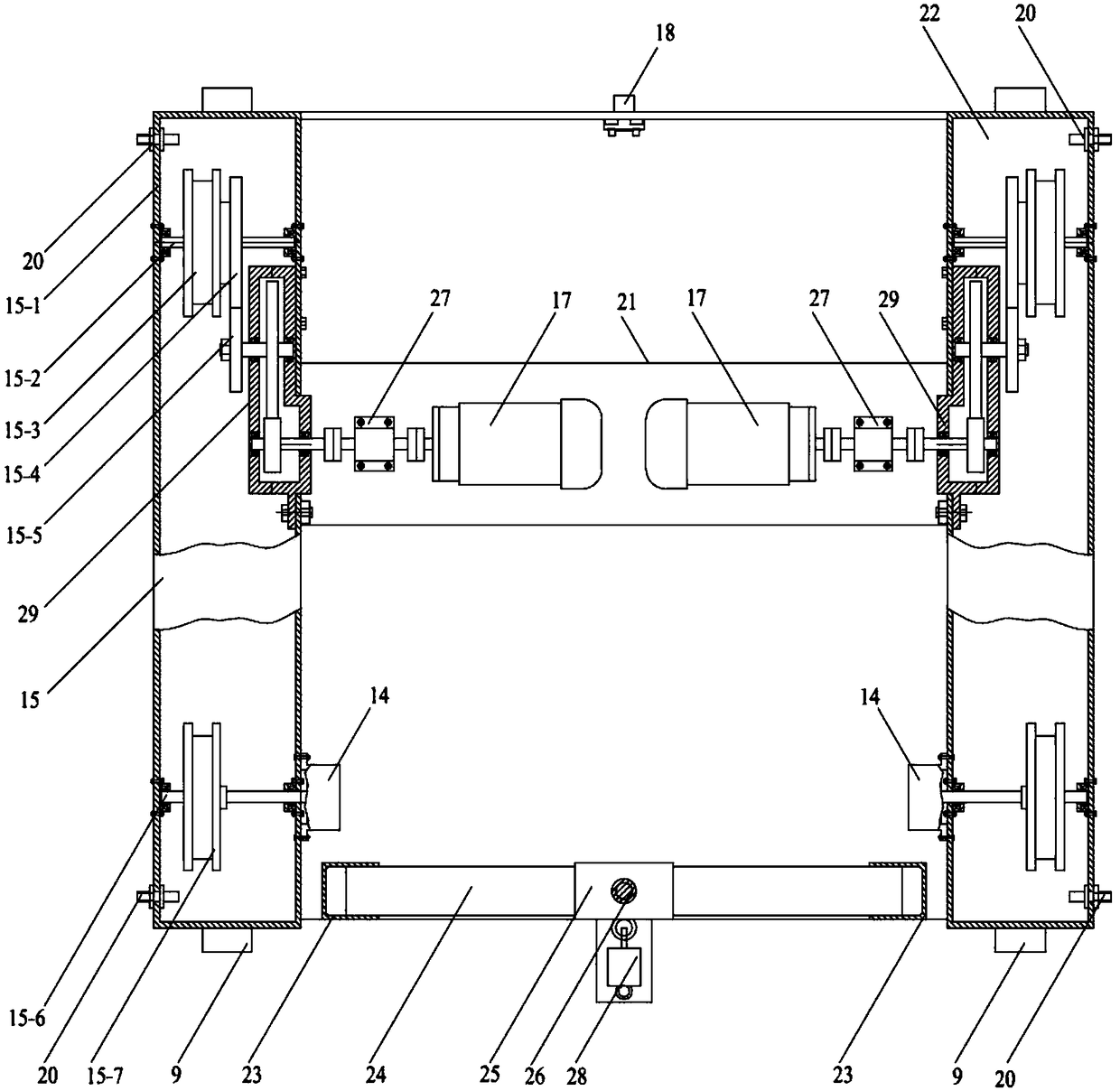

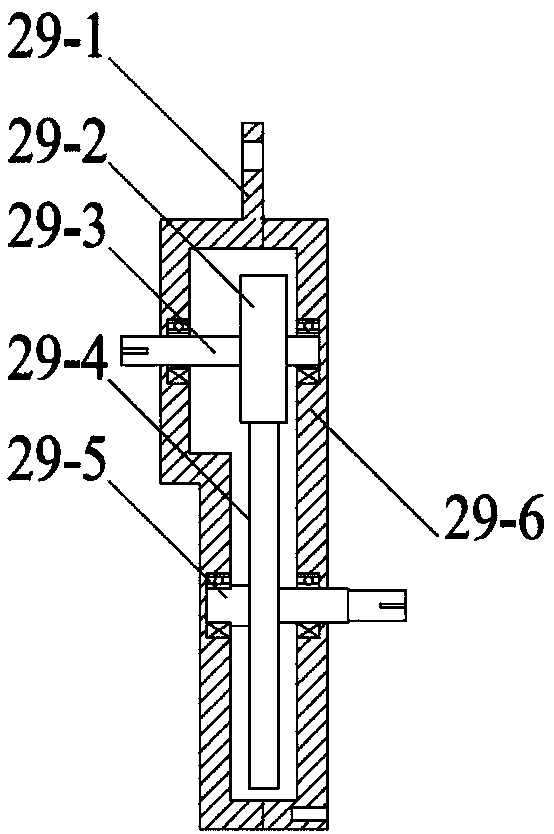

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the device-soil action force soil tank test detection device is characterized in that it includes a soil tank, a traction assembly, a control assembly, and a data acquisition assembly.

[0033] The soil tank includes base 1, tank box 2, track 3, inner tank 4, drain pipe 5, valve 6, longitudinal bottom beam 7, buffer block 9, limit pile 10, contour detection pipe 11, and multi-support base 1 Horizontally uniformly fixed on the ground, the upper surface of each base 1 is on the same level, the tank box 2 is a rectangular frame, the bottom of the tank box 2 is fixed on multiple bases 1, and multiple vertical bottom beams 7 are longitudinally fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com