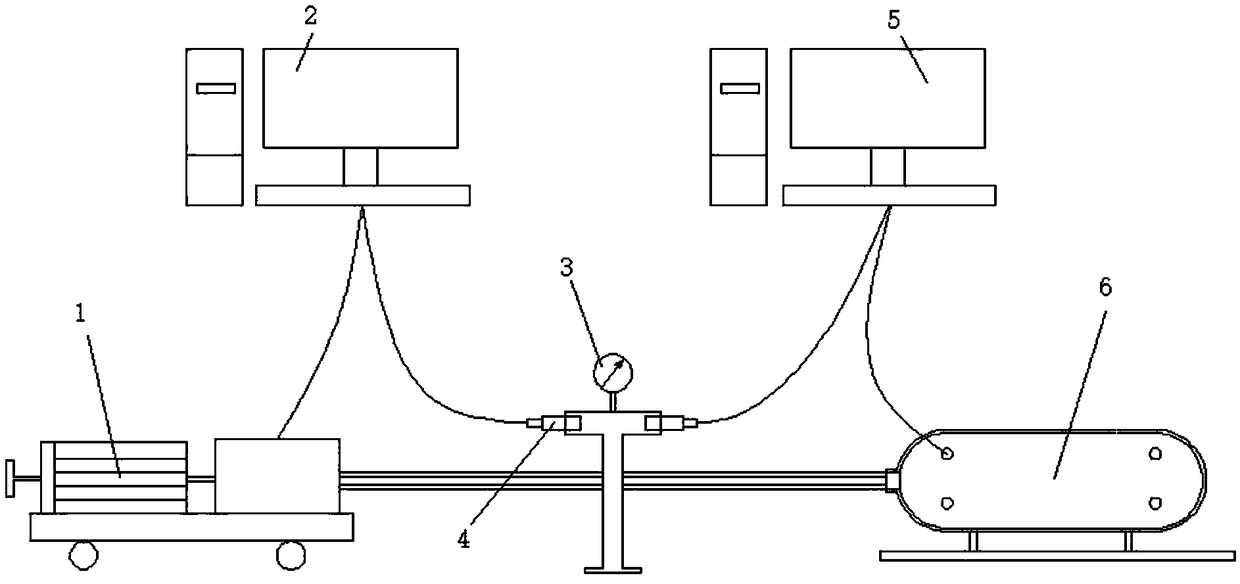

Device and method for monitoring hydraulic blasting of composite gas cylinder on basis of acoustic emission technique

An acoustic emission technology and composite material technology, which is applied in the field of composite gas cylinder water pressure blasting monitoring devices based on acoustic emission technology, can solve problems such as sensor damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

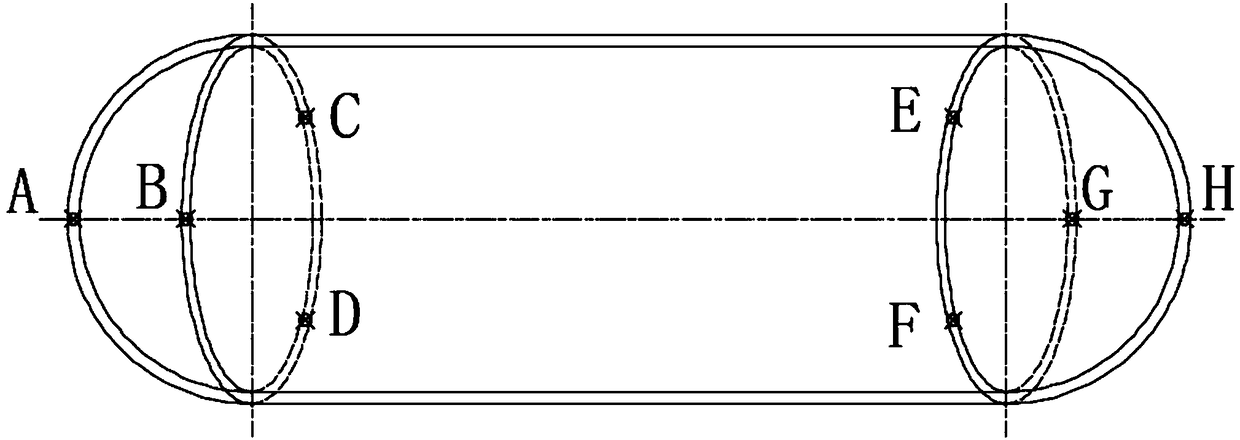

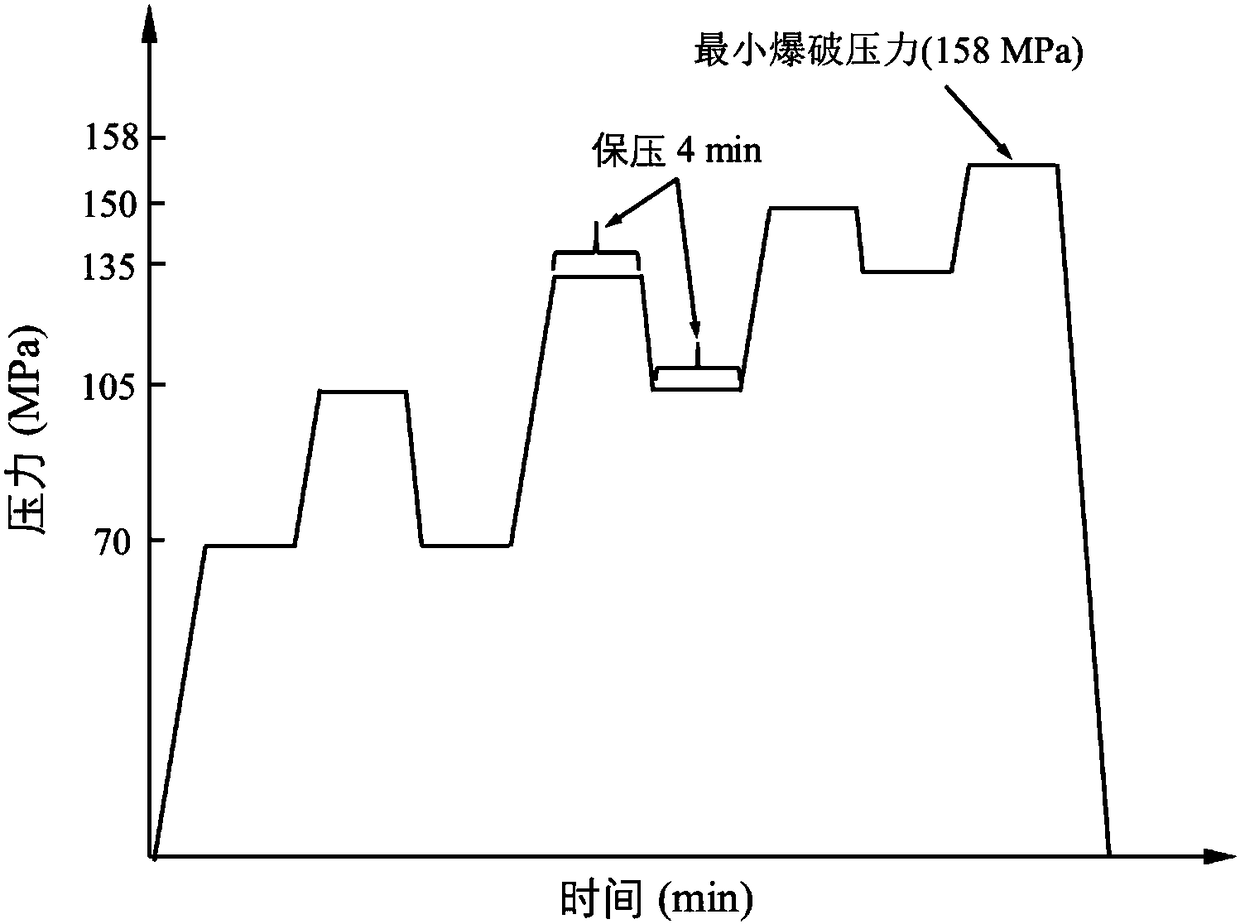

Method used

Image

Examples

Embodiment Construction

[0036] First of all, it needs to be explained that the present invention is an application of acoustic emission technology in the field of on-line monitoring of carbon fiber composite gas cylinder hydraulic blasting damage. Both the acoustic emission detection system and the broadband sensor are commercially available products (such as the existing equipment of the American Physical Acoustics Corporation), and sound velocity measurement, attenuation characteristic analysis, and positioning calibration are prior art well known to those skilled in the art. The applicant believes that, after carefully reading the application documents and accurately understanding the realization principle and purpose of the present invention, combined with the existing known technology, those skilled in the art can fully use the composite material acoustic emission detection technology they have mastered to realize this invention. Everything mentioned in the application documents of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com