Current probe

A current probe and current needle technology, applied in the field of current probes, can solve problems such as puncture, uneven needle surface, abnormal needle burning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

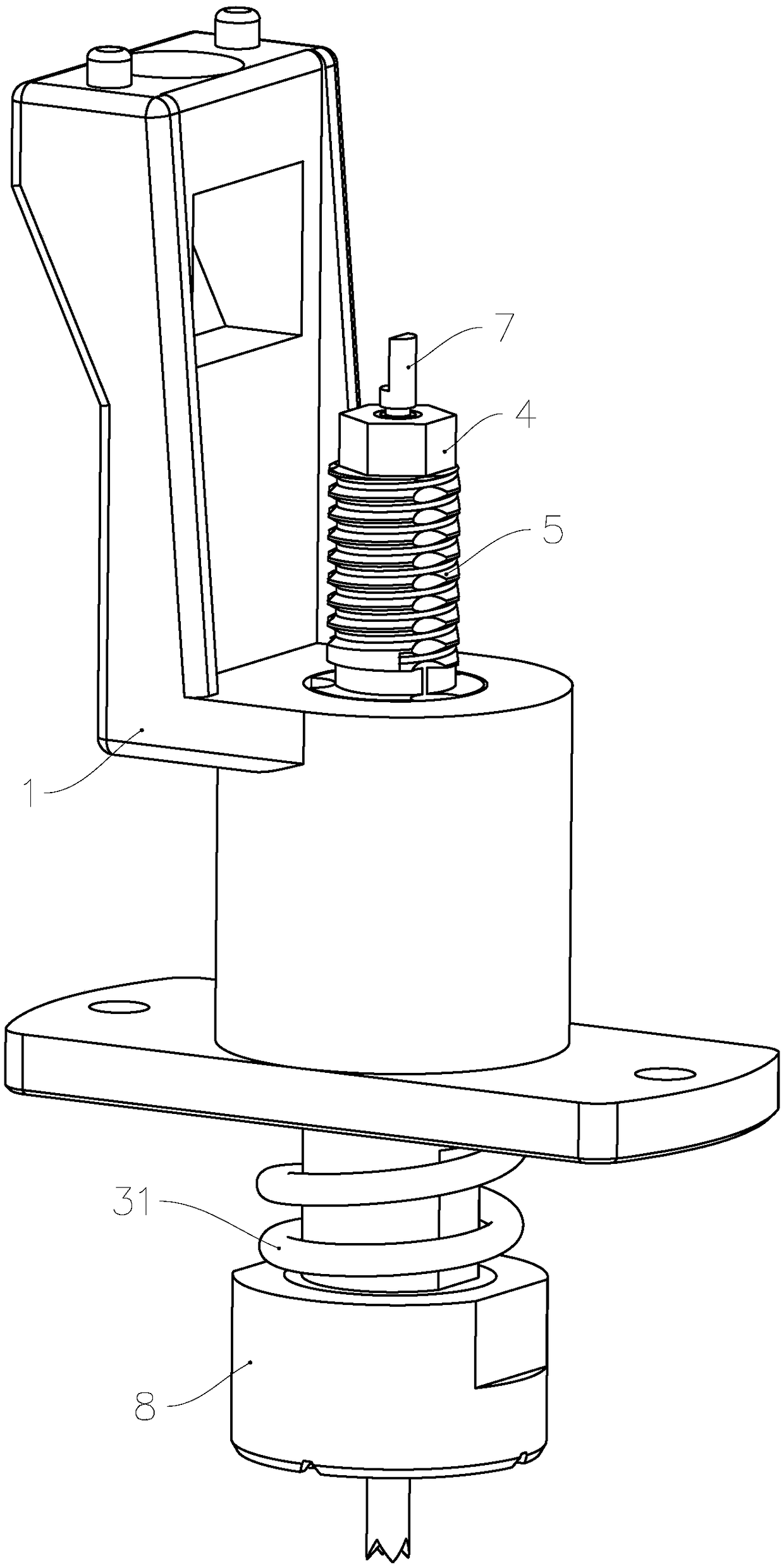

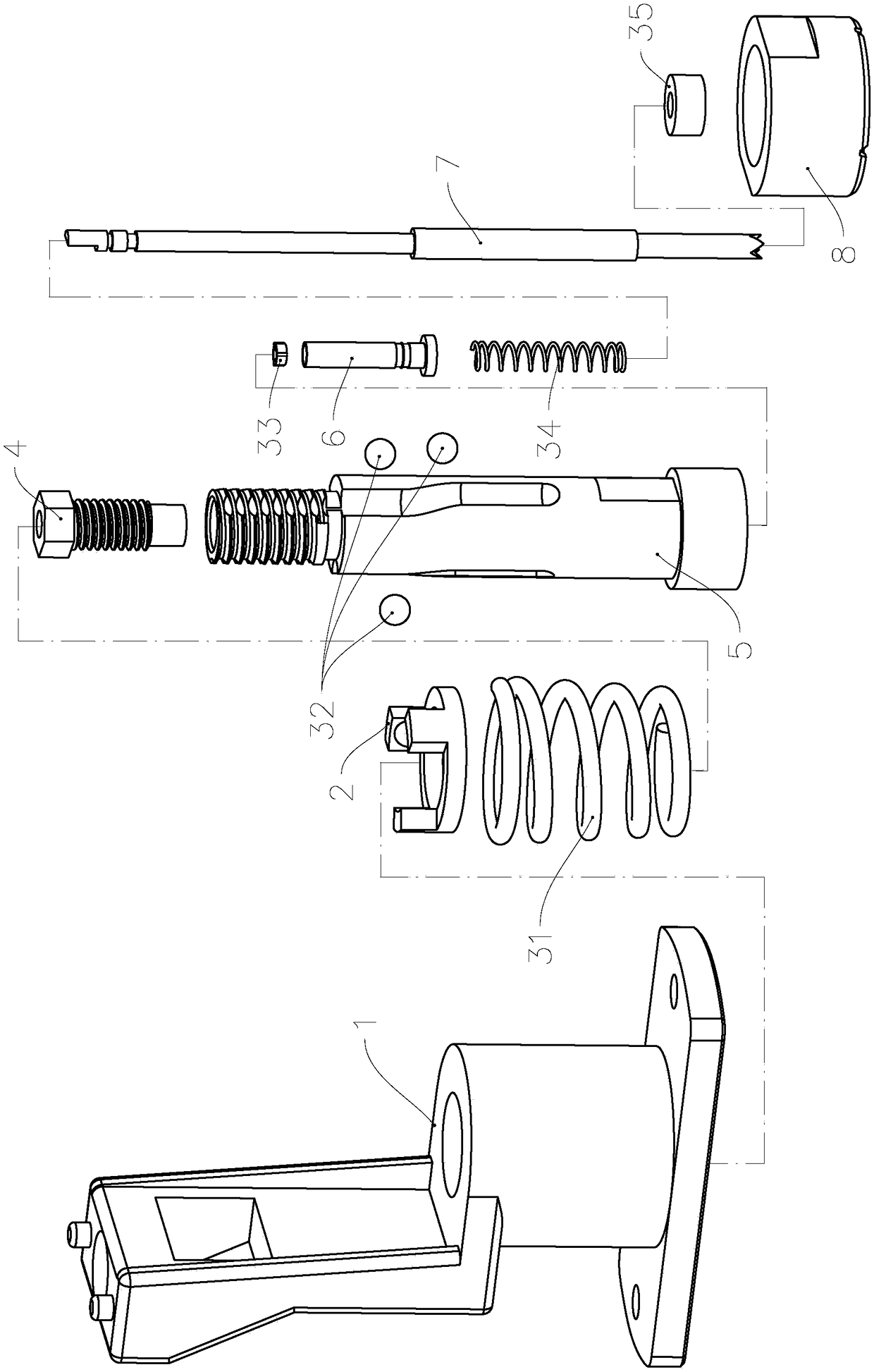

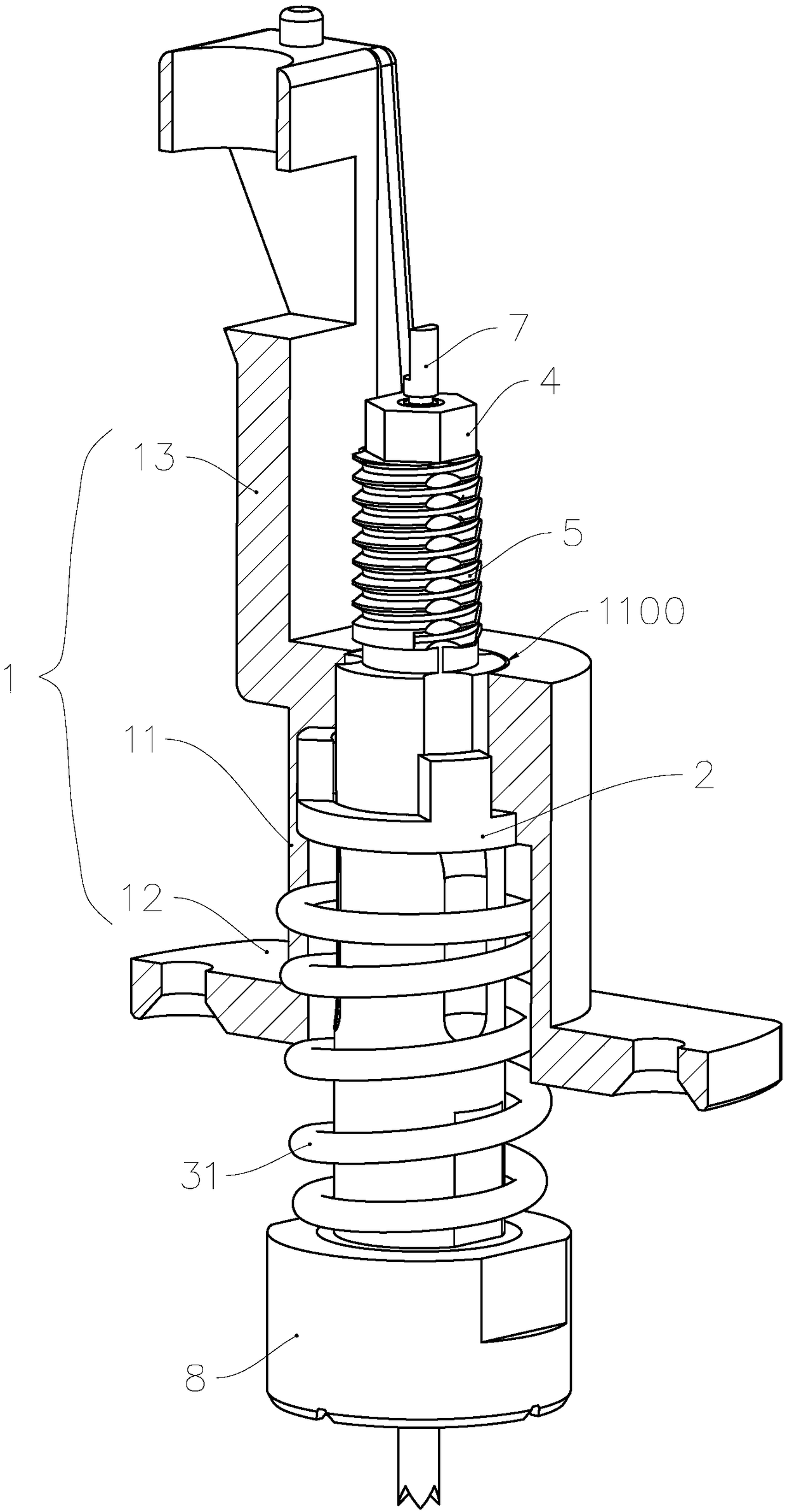

[0034] see Figure 1 to Figure 12 , the current probe of the present invention includes a mount 1 and a ball mount 2 mounted on the mount 1, a second compression spring 31, three balls 32, a first compression spring 34, a lower insulating ring 35, an upper insulating ring 4. Current needle tube and sampling needle rod.

[0035] Such as image 3 and Figure 4 As shown, the mounting base 1 includes a sleeve portion 11, a mounting lug 12 fixed on the lower end of the sleeve portion 11, and an anti-outer seat fixed on the upper end of the sleeve portion 11 and made in an integrated manner. The wiring fixing column 13 for cable traction; the top of the wiring fixing column 13 is connected with the base pipe 5 by a nut with a flexible connection wire; the wiring fixing column 13 deviates outward from the axial direction of the casing part 11 to avoid the current needle tube and the sampling needle bar. In the mounting base 11 , at least the bushing part 11 is made of insulating m...

Embodiment 2

[0057] As a description of Embodiment 2 of the present invention, only the differences from Embodiment 1 above will be described below.

[0058] see Figure 13 , the current terminal 8 protrudes to form a multi-circle diamond-shaped or rectangular contact bump 80. During use, the contact bump 80 is used to contact the surface of the tab to brush off the high-resistance coating, and to achieve planar contact. conduct electricity.

Embodiment 3

[0060] As an explanation of Embodiment 3 of the present invention, only the differences from Embodiment 1 above will be described below.

[0061] see Figure 14 , replace the second compression spring with a torsion spring, cancel the ball mounting bracket, and use the guide post 32 formed by the protrusion on the inner surface of the casing to replace the ball, and use the guide surface 51 on the outer surface of the base tube to replace the ball guide groove, The torsional restoring force of the torsion spring forces the guide post 32 to always press against the guiding surface 51, and the axial restoring force forces the current terminal away from the mounting seat. The guiding surface 51 includes straight sections 511, 512 arranged axially along the base tube and smooth connections. The inclined surface 510 of the two, in the process of sliding the guide post along the inclined surface 510, realizes the transformation of the displacement and realizes the rotation of the dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com