Single battery with super capacity and preparation method thereof

A single cell and capacity technology, applied in secondary battery manufacturing, electrolyte storage battery manufacturing, large flat battery/battery, etc. Problems such as large column pressure drop, to achieve the effect of large plasticity, simple design and simplified welding tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to meet the needs of power batteries and energy storage batteries for improving battery capacity and performance, multiple small-capacity batteries are often combined in parallel to achieve this. However, this prior art has the following disadvantages: the number of battery pole pieces is large; the pole group is electrically connected to the pole Difficult, the riveting process is often used, and the voltage drop is too large when the riveting point is electrically connected to the pole, which affects the power output characteristics of the battery; due to the large battery capacity and the large thickness of the pole group, it is easy to cause the middle part of the pole group and The large external temperature gradient causes the local capacity to decay too quickly, which seriously affects the cycle life of the battery.

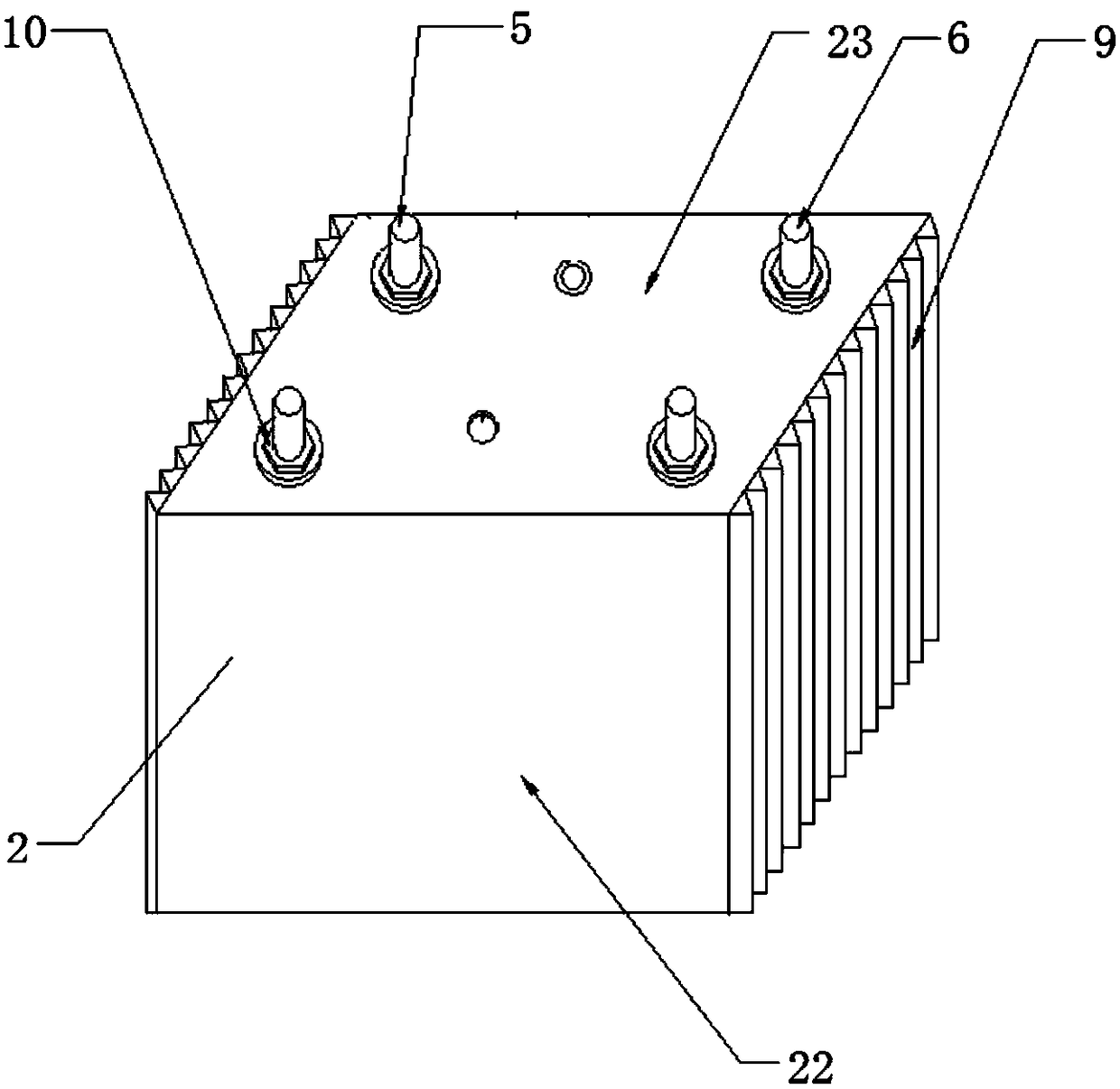

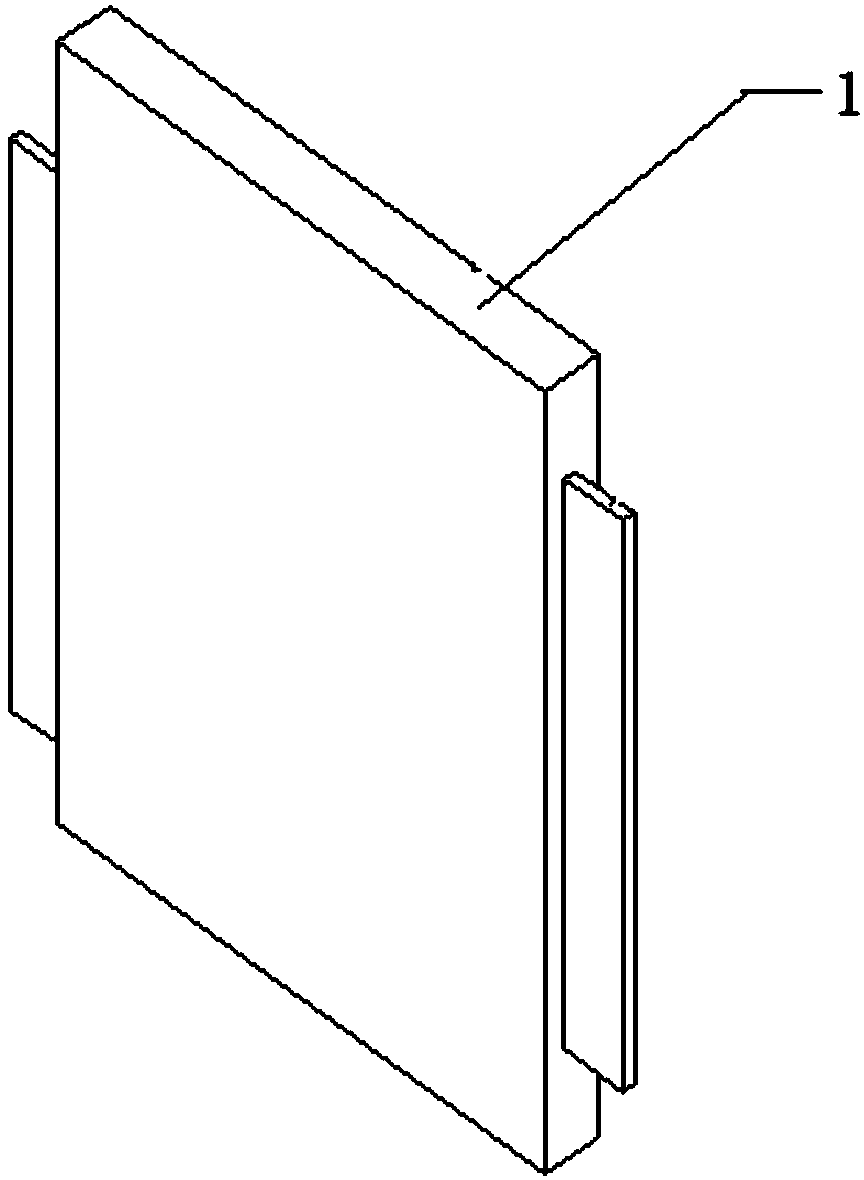

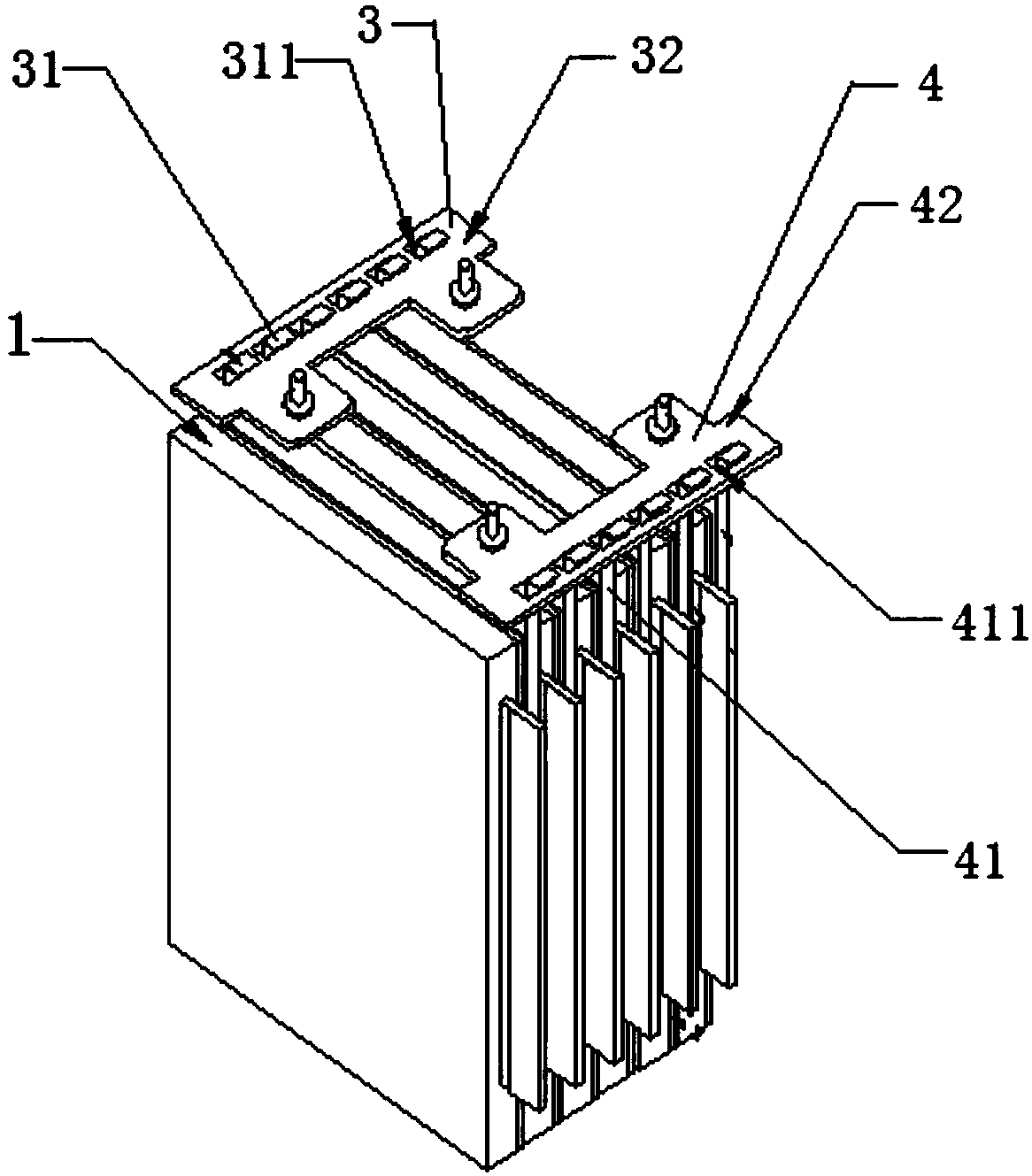

[0040] In order to solve the above problems, the present invention proposes a single battery with super large capacity, such as figure 2 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap