Mounting device for sub-gun probe with sampling port positioning and method of use thereof

A technology of installation device and sampling port, applied in the field of sub-gun probe installation device, can solve the problems of unfavorable steelmaking composition control, weakening the representativeness of samples, etc., and achieve the effect of less equipment maintenance, simple structure, and improved steelmaking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

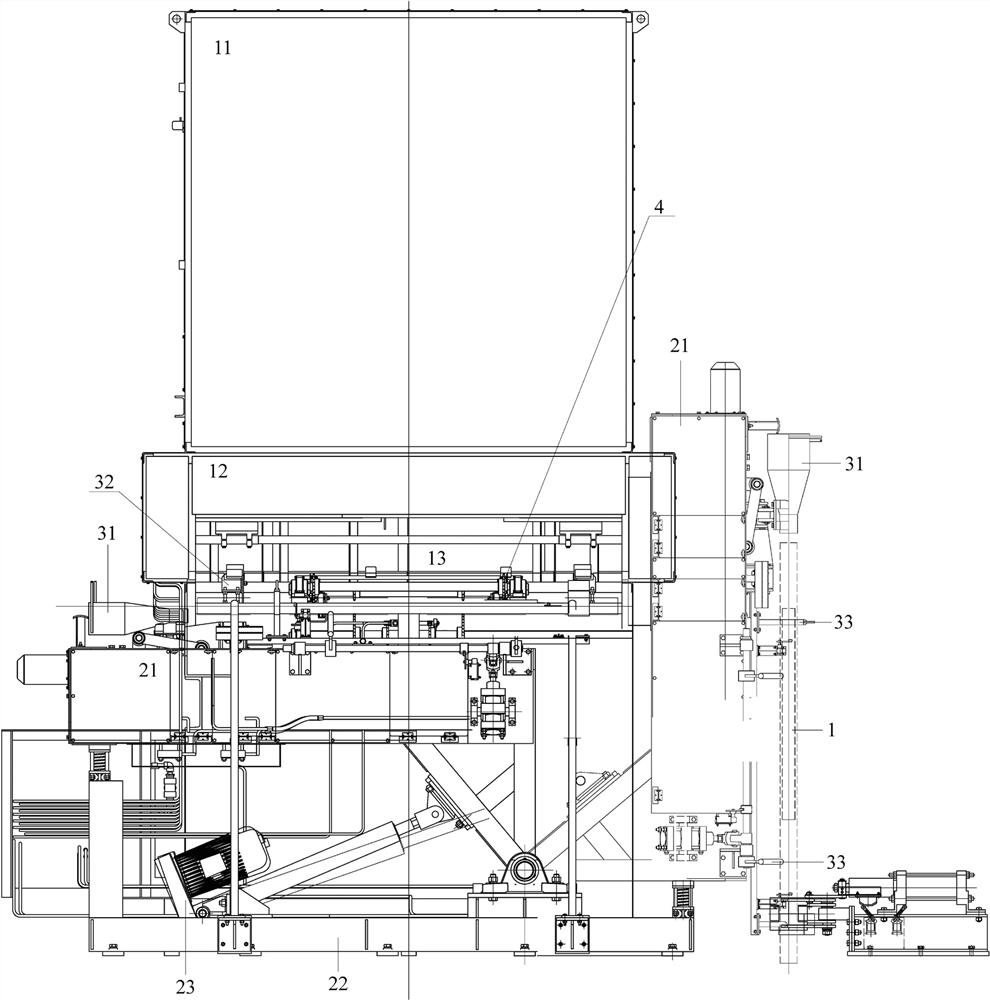

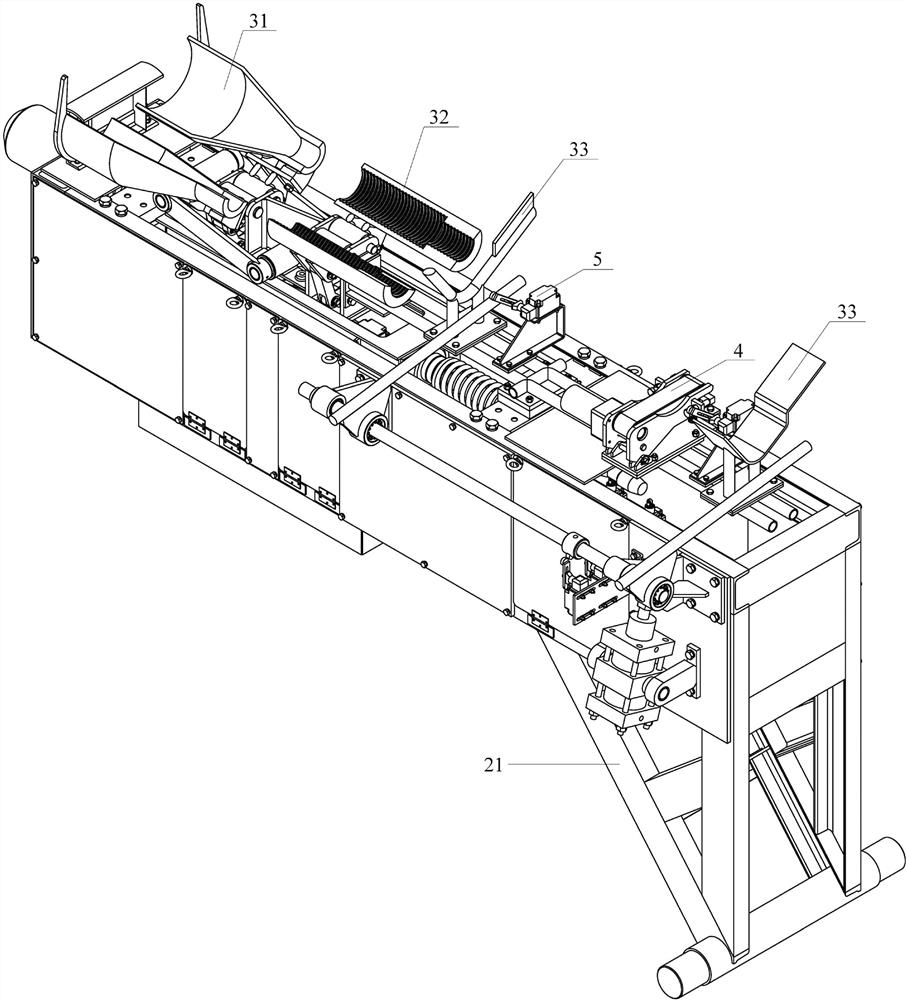

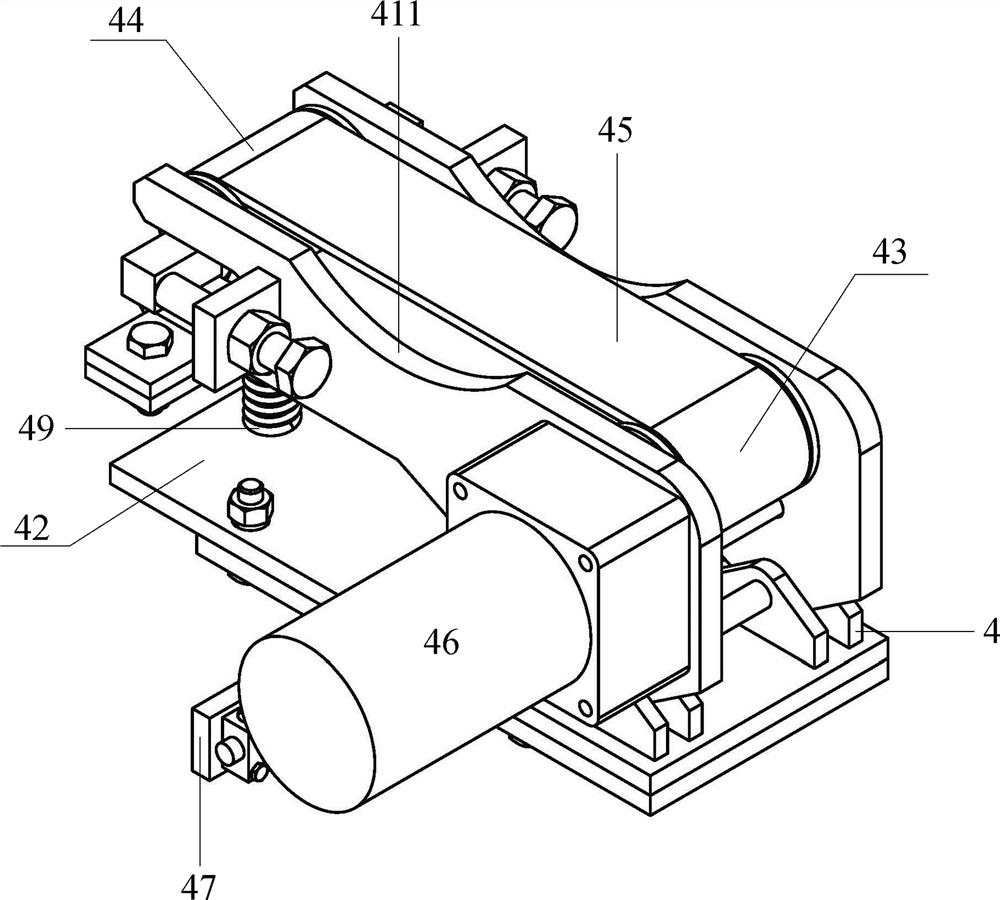

[0027] A sub-gun probe installation device with sampling port positioning, including a sub-gun probe 1, a storage box 11, a selection device 12, a conveying device 13, an overturning frame 21, a base 22, a drive cylinder 23, a guide bucket 31, and a gripper 32 , bracket 33, positioning device 4 and detection switch 5, such as Figure 1 to Figure 4 As shown, the specific structure is:

[0028] The auxiliary gun probe 1 is horizontally arranged in the probe storage box 11, and the selection device 12 is arranged at the exit of the probe storage box 11, and the exit of the selection device 12 is facing the conveying device 13,

[0029] The structure of the storage box 11 is designed as five independent storage spaces, which are suitable for classifying and storing five different probes. The selection device 12 is responsible for selecting a specific type of probe. A complete set of sub-lance equipment is to provide temperature, carbon content and oxygen content measurement and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com