Automatic control system for RH refining equipment of steel mill

An automatic control system and refining equipment technology, applied in the field of control, can solve the problems of difficulty in model adjustment, cost reduction, no complete set of RH refining simulation control, etc., achieve good economic benefits, improve simulation and production efficiency, efficient prediction simulation and automatic control. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

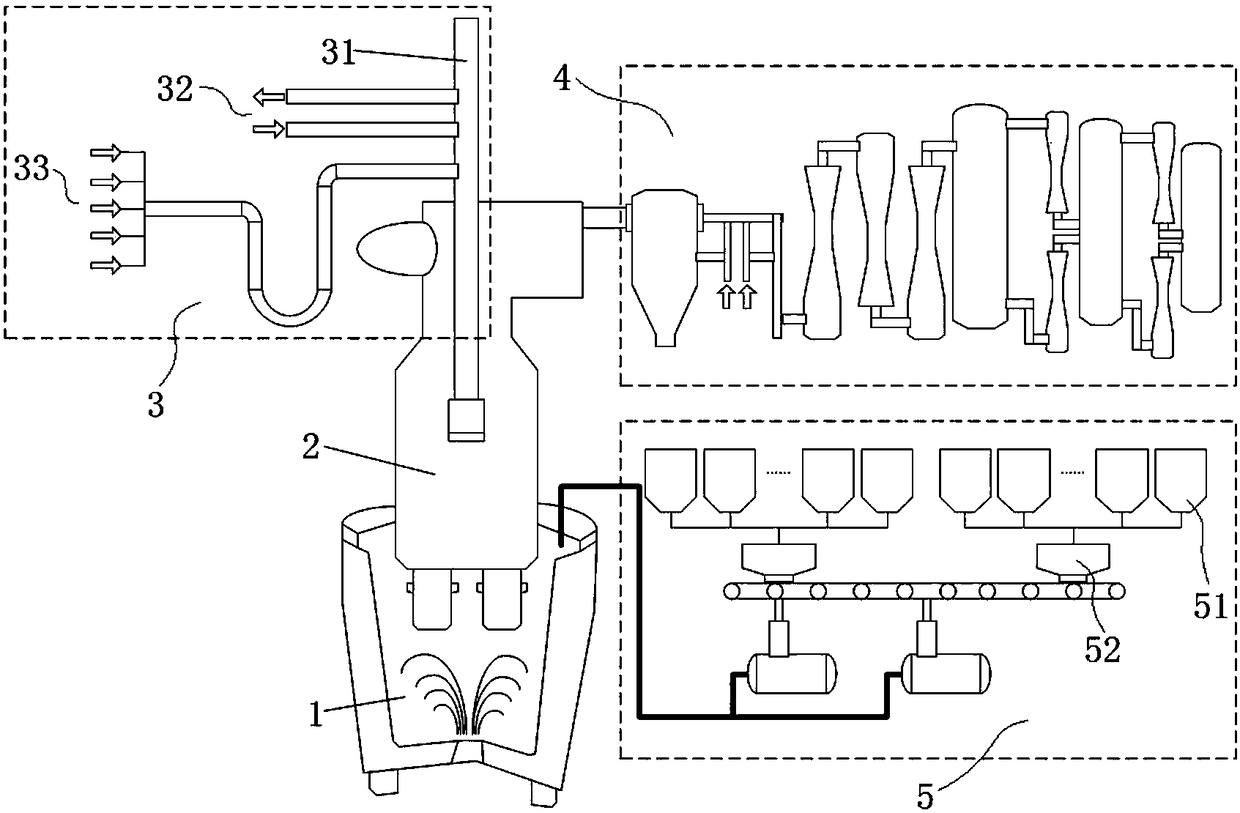

[0036] Such as figure 1 Shown is a schematic diagram of the composition of RH refining equipment, which includes a ladle 1, a vacuum chamber 2, an oxygen lance system 3, a vacuum pump system 4 and an alloy system 5, wherein the oxygen lance system 3 includes an oxygen lance 31, a cooling water unit 32 and a gas distribution unit 33. The alloy system 5 includes an alloy silo 51 and weighing 52, etc. Since the specific structure and composition of the RH refining equipment are well known to those skilled in the art, it will not be described in detail here.

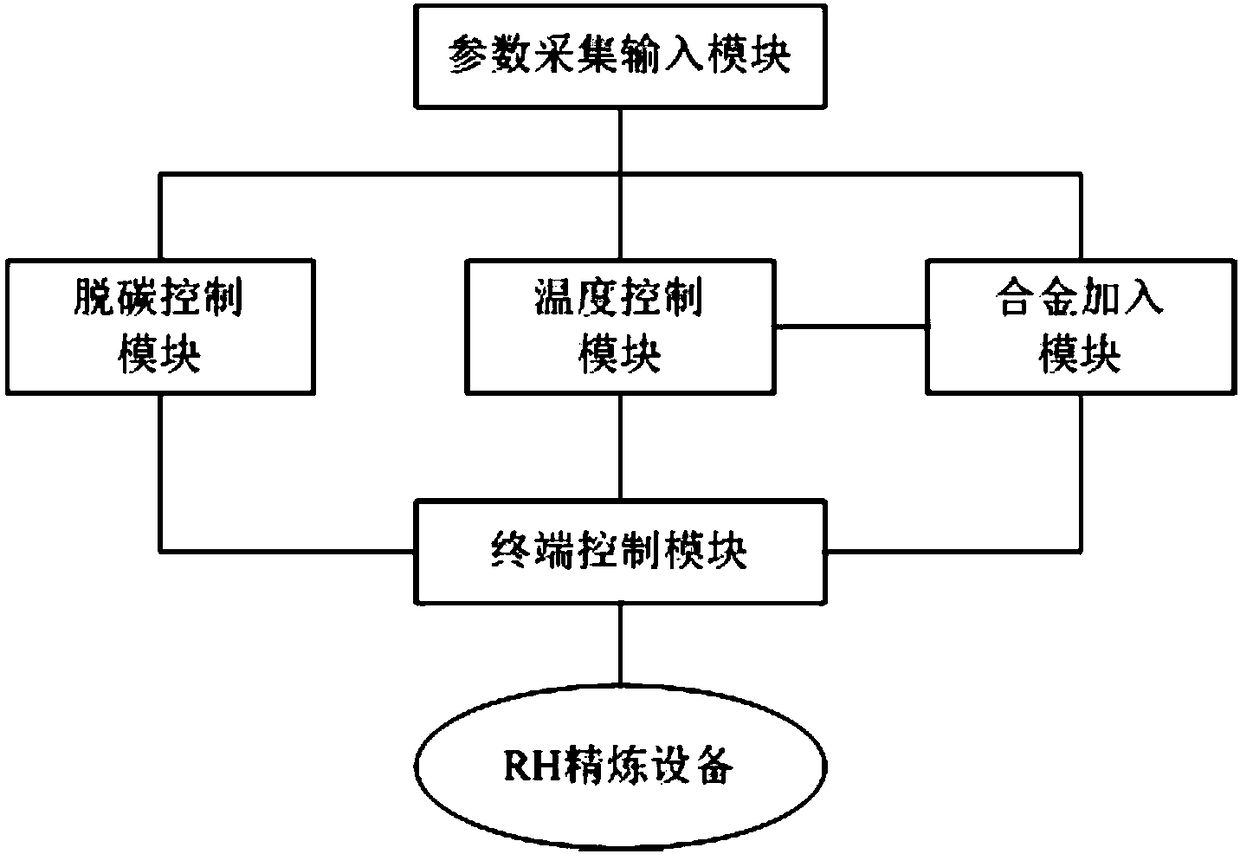

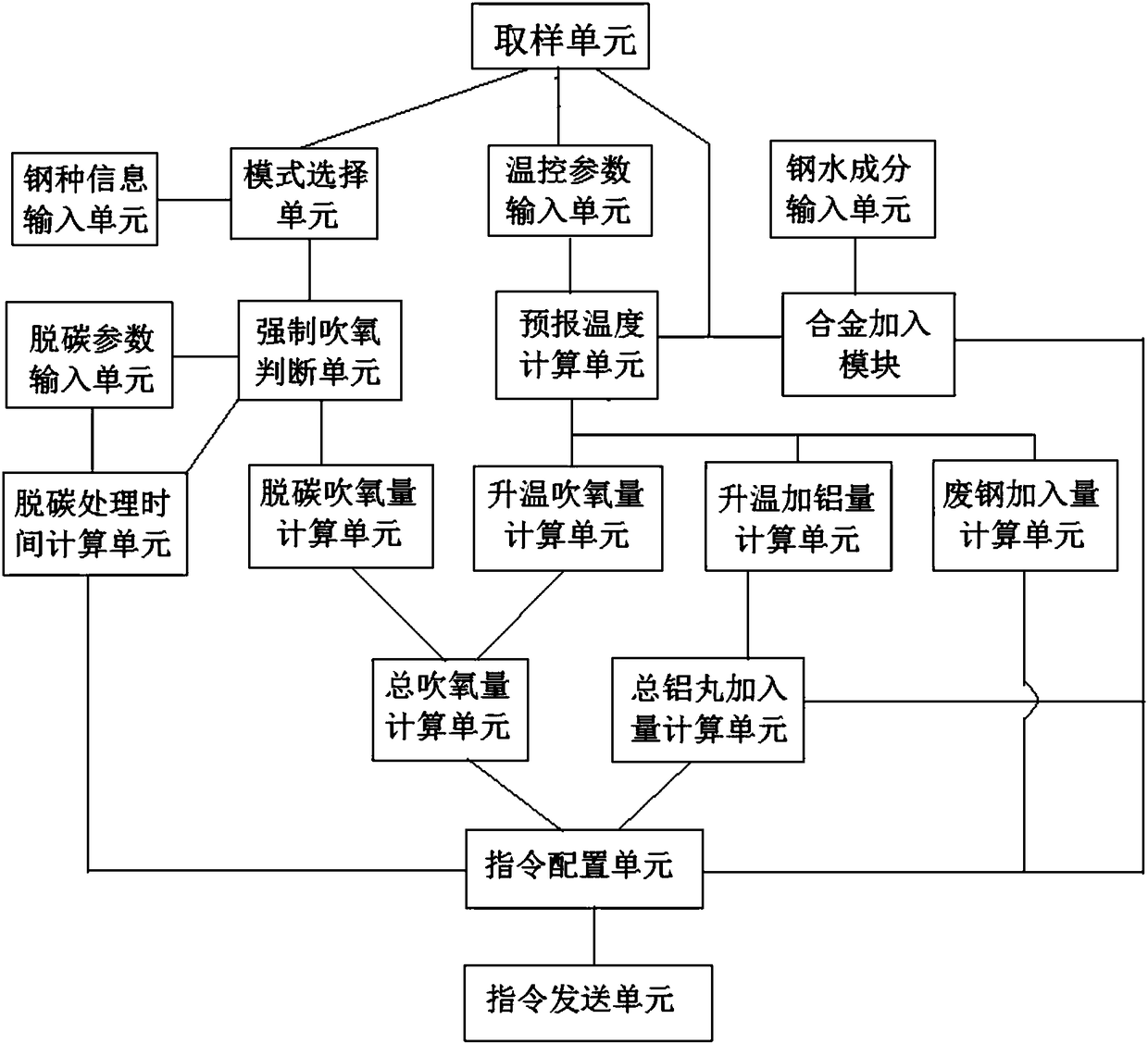

[0037] Such as figure 2 As shown, the present invention provides a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap