Reversing device of pumping unit

A technology of reversing device and pumping unit, which is applied in the direction of production fluid, wellbore/well parts, earthwork drilling and production, etc., which can solve the problems of heavy load and high energy consumption, and achieve the purpose of improving service life, saving energy and reducing energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

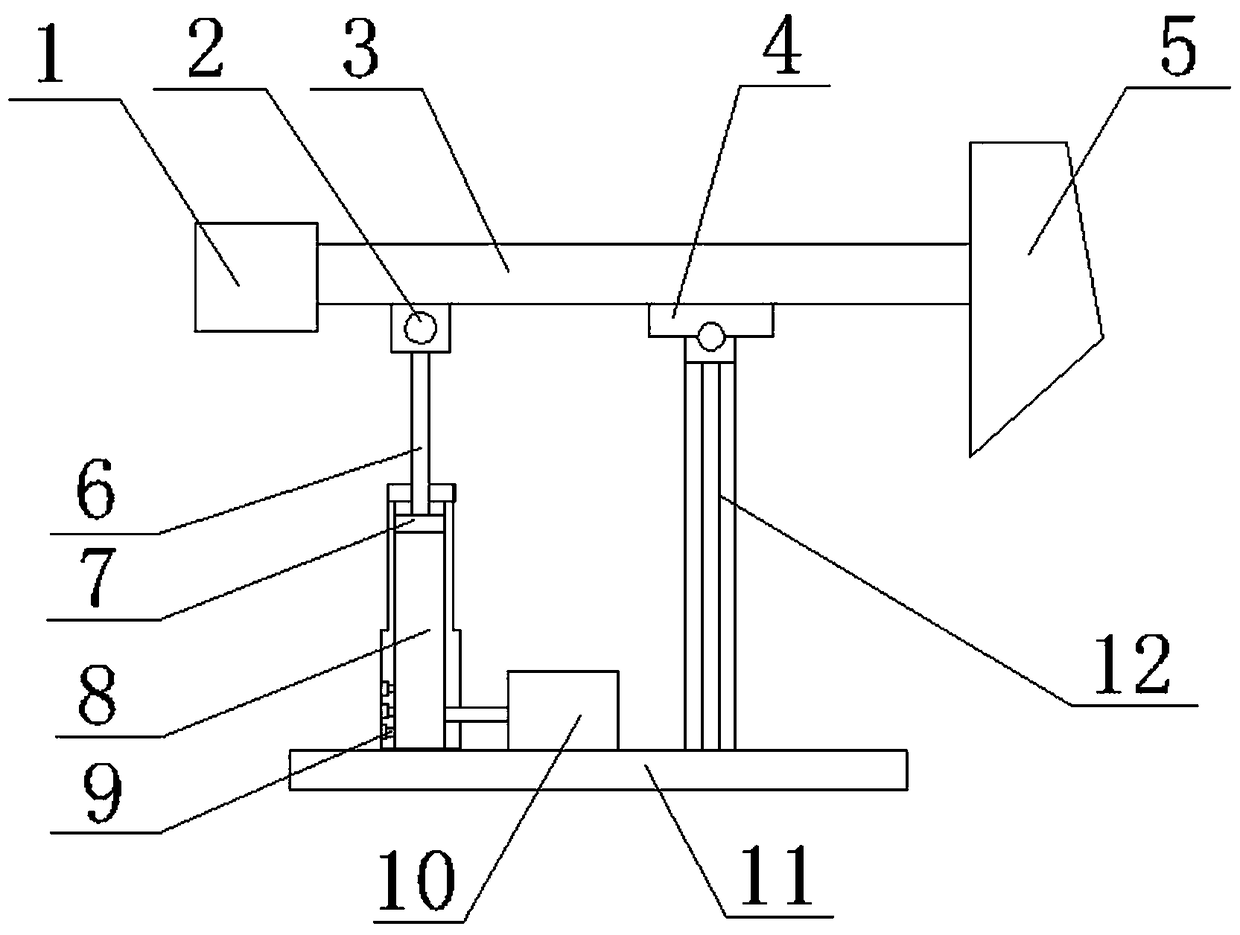

[0014] A reversing device for a pumping unit, comprising a base 11, a beam 3 and a piston mechanism 8, the left side of the beam 3 is provided with a counterweight box 1, the right side of the beam 3 is a donkey head 5, and the beam 3 is connected to the bracket through the hinge mechanism 4 12, the bracket 12 is set on the base 11, the piston mechanism 8 is set on the base 11, the right side of the piston mechanism 8 is connected to the air pump 10, the piston mechanism 8 is provided with a piston 7, and the piston 7 is connected to the connecting rod 6 , the connecting rod 6 is connected with the beam 3 through the hinge mechanism 2, and the piston mechanism 8 is provided with an electromagnetic valve 9. An application method of the reversing device of a pumping unit is as follows: when the pumping device is started, the air pump 10 rushes high-pressure gas into the piston mechanism 8, the electromagnetic valve 9 is closed, and the piston 7 moves upward under the action of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap