Commercial exhaust kitchen

A kitchen and commercial technology, applied in the field of exhaust kitchens, can solve the problems of poor exhaust, damage to the appearance of building facades, pollution, etc., to achieve the effects of easy installation and fixing, economical cost savings, and increased air replenishment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

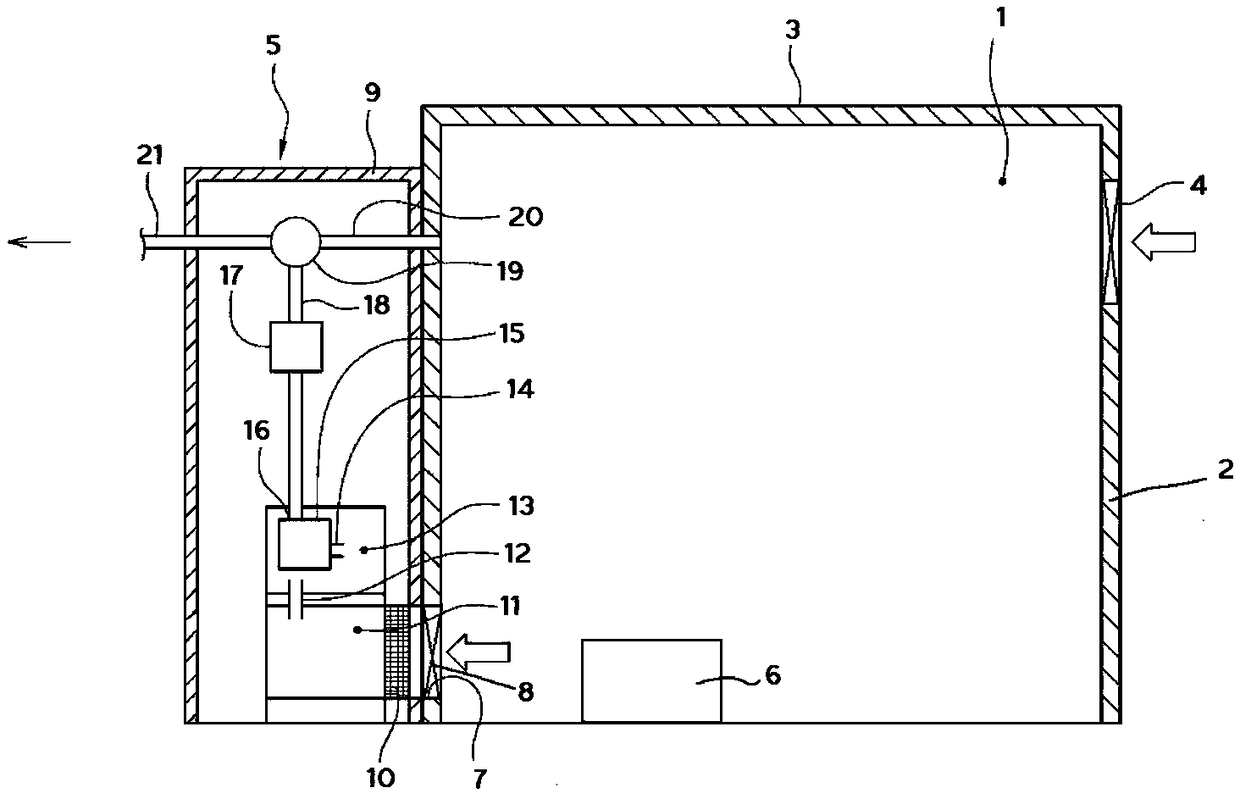

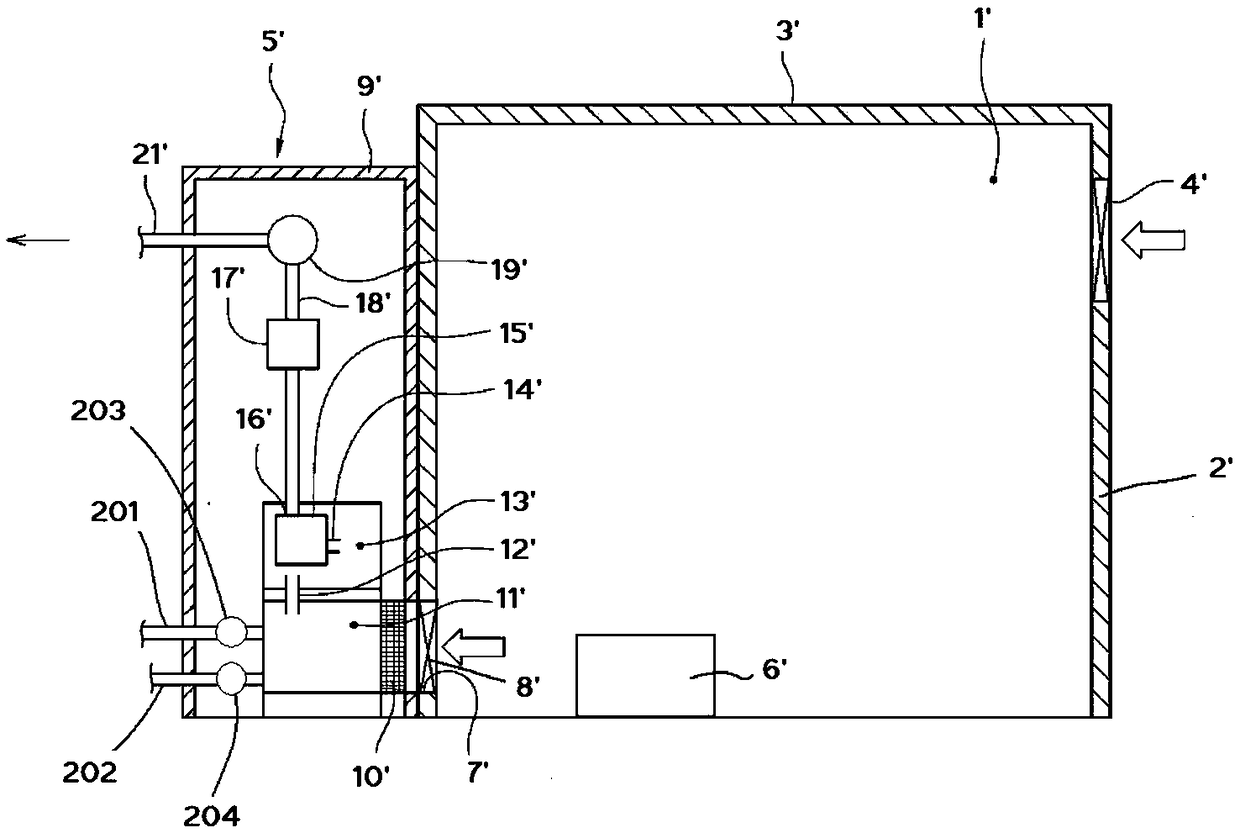

[0034] Such as Figure 2-3 As shown, a commercial exhaust kitchen 1' includes a kitchen side wall 2', a kitchen ceiling 3', an exhaust fan 4', an external exhaust device 5', and a gas stove large pot stove 6', wherein the Exhaust device 5' is arranged on the outside of the kitchen side wall, and the gas stove cauldron stove is arranged inside the kitchen; a range hood is arranged above the gas stove cauldron stove (not shown in the figure, but It will be clear to those skilled in the art), and an exhaust air duct 7' is provided near the kitchen side wall of the external exhaust device, and an exhaust fan 8' is arranged on the exhaust air duct 7', and the range hood exhaust fume The pipeline is connected with the exhaust passage 7' (not shown in the figure, but those skilled in the art can understand); The first oil fume collecting chamber 11', the first connecting pipe 12', the second oil fume collecting chamber 13', the second connecting pipe 14', the secondary filtering equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com