Motor drive device

A driving device and motor technology, which is applied in motor control, motor generator control, AC motor control, etc., and can solve problems such as abnormality of the power input part 4 and inability to detect equipment 5 faults, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

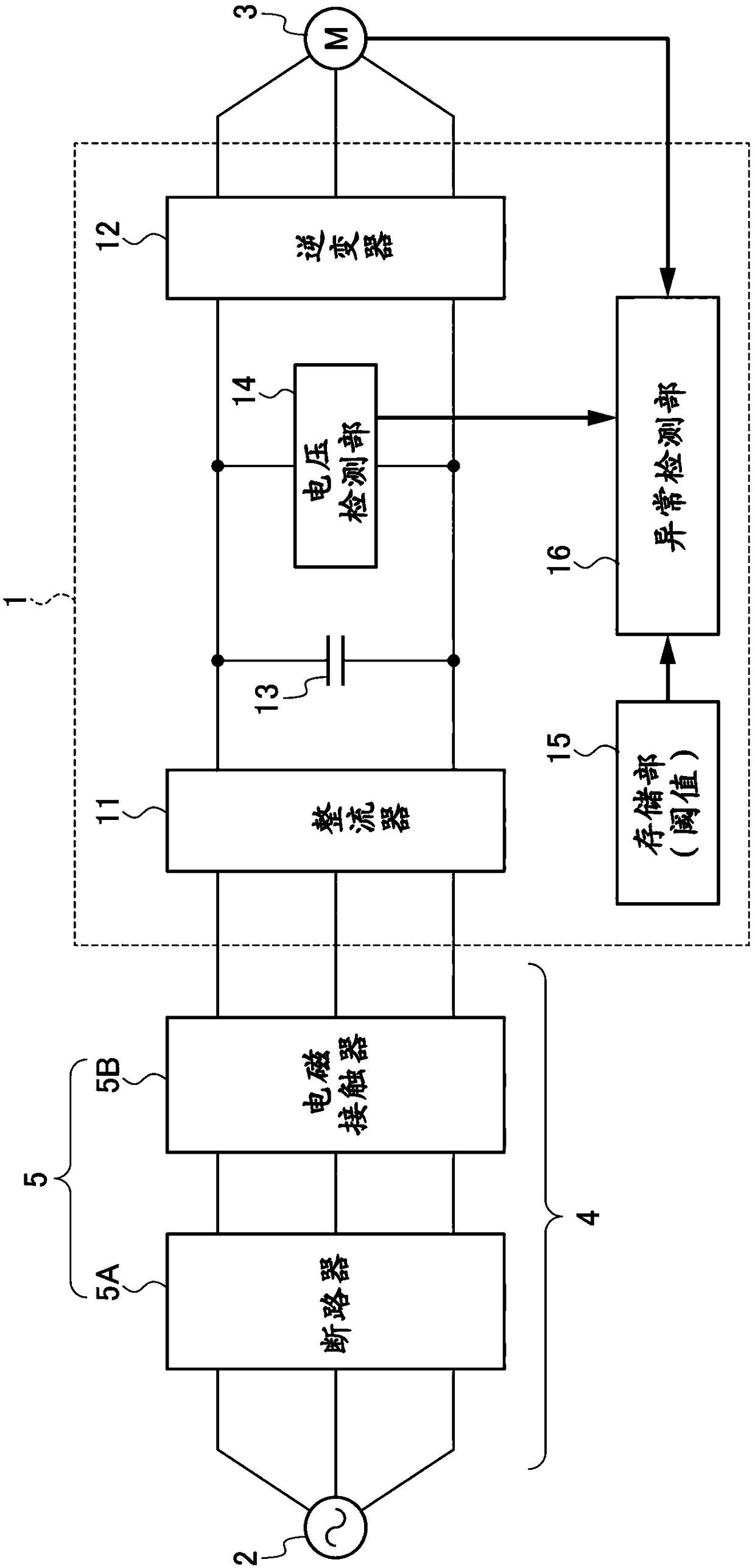

[0036] figure 1 It is a diagram showing the circuit configuration of the motor drive device according to the first embodiment of the present invention. figure 1 The illustrated motor drive device 1 inputs three-phase AC power from a commercial three-phase AC power source 2 and drives a motor 3 . In addition, the AC power supply 2 is not limited to a three-phase AC, and may be a single-phase AC, for example.

[0037] Devices 5 such as a circuit breaker 5A and an electromagnetic contactor 5B are provided in the power input unit 4 between the motor drive device 1 and the AC power supply 2 .

[0038] The motor drive device 1 includes a rectifier 11 , an inverter 12 , a DC link capacitor 13 , a voltage detection unit 14 , a storage unit 15 , and an abnormality detection unit 16 .

[0039] The rectifier 11 converts the AC power from the AC power supply 2 into DC power. The rectifier 11 is constituted by, for example, a diode rectification converter or a PWM converter having a b...

no. 2 Embodiment approach

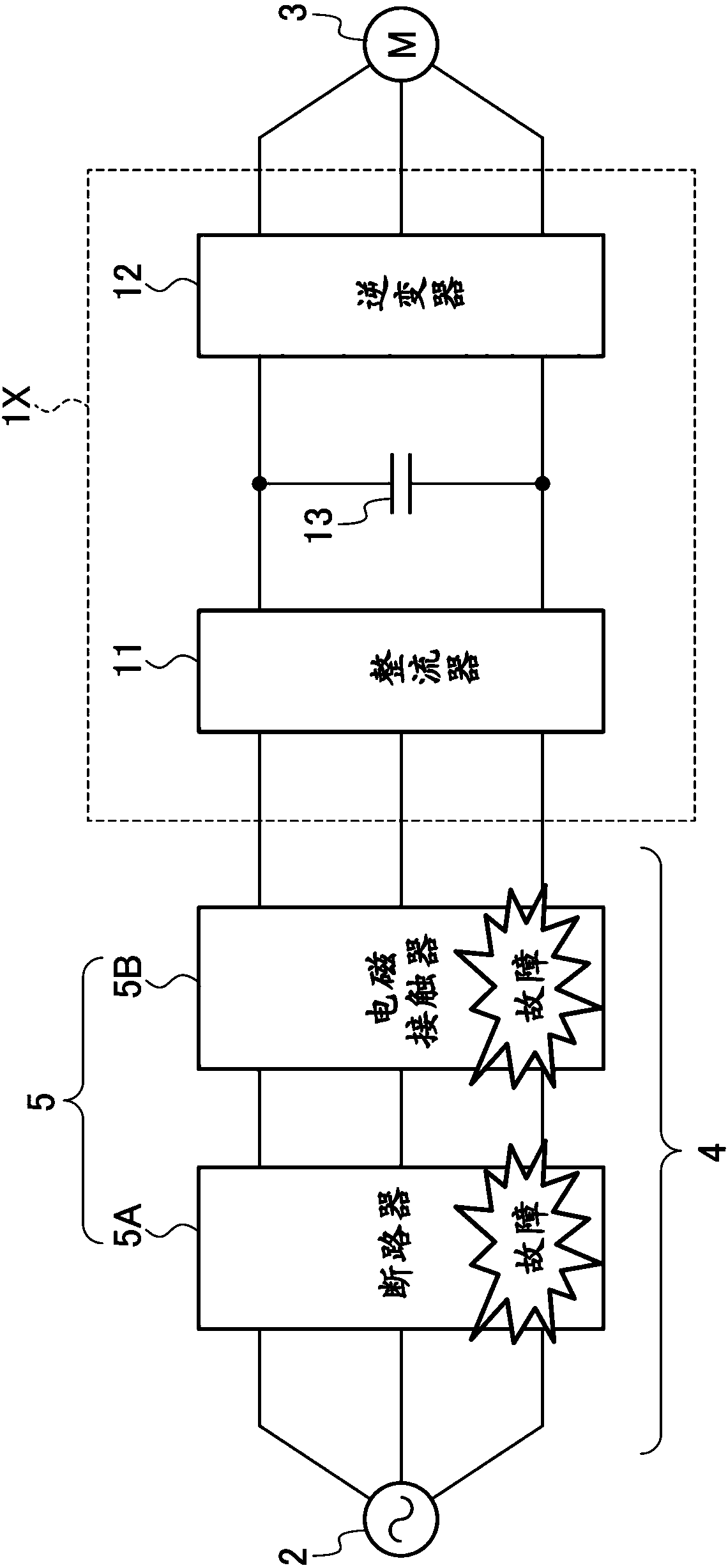

[0062] In the first embodiment, a failure of the device 5 (abnormality of the power supply input unit 4 ) is detected during acceleration or deceleration of the motor 3 based on the amount of voltage change per unit time of the DC link capacitor 13 . In the second embodiment, a failure of the device 5 (power input unit 4 exception).

[0063] The structure of the motor drive device 1 according to the second embodiment and figure 1 The configuration of the motor drive device 1 of the first embodiment shown is the same. In addition, in the motor drive device 1 according to the second embodiment, the function and operation of the abnormality detection unit 16 and the threshold value stored in the storage unit 15 are different from the motor drive device 1 of the first embodiment.

[0064] The storage section 15 stores in advance a threshold value for detecting a voltage change of the DC link capacitor 13 for a predetermined time due to a failure of the device 5 (ie, an abnormal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com