Combine

A technology for combine harvesters and grain harvesting, which is applied to harvesters, cutters, agricultural machinery and implements, etc., and can solve problems such as the simplified structure of the threshing unit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

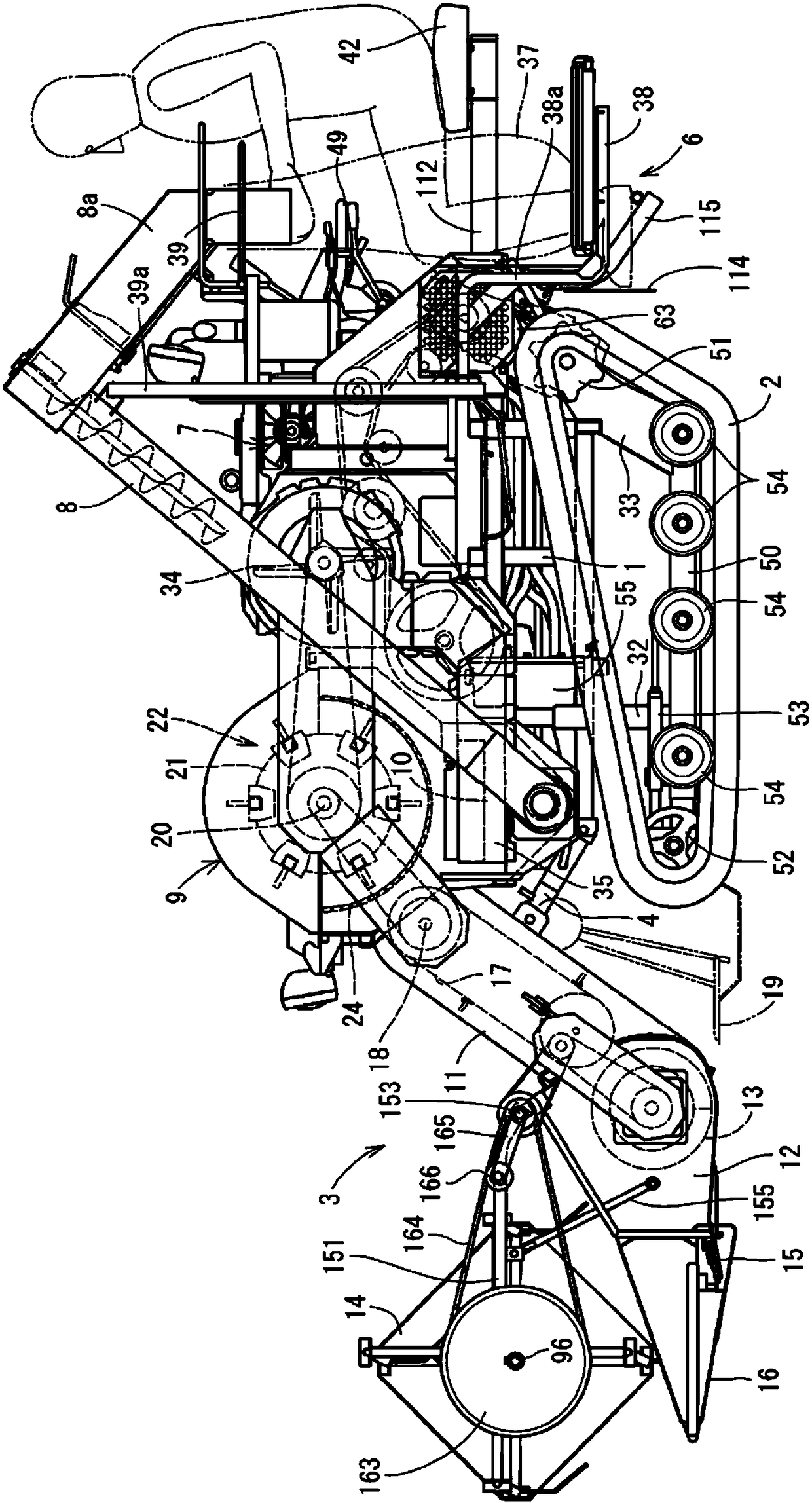

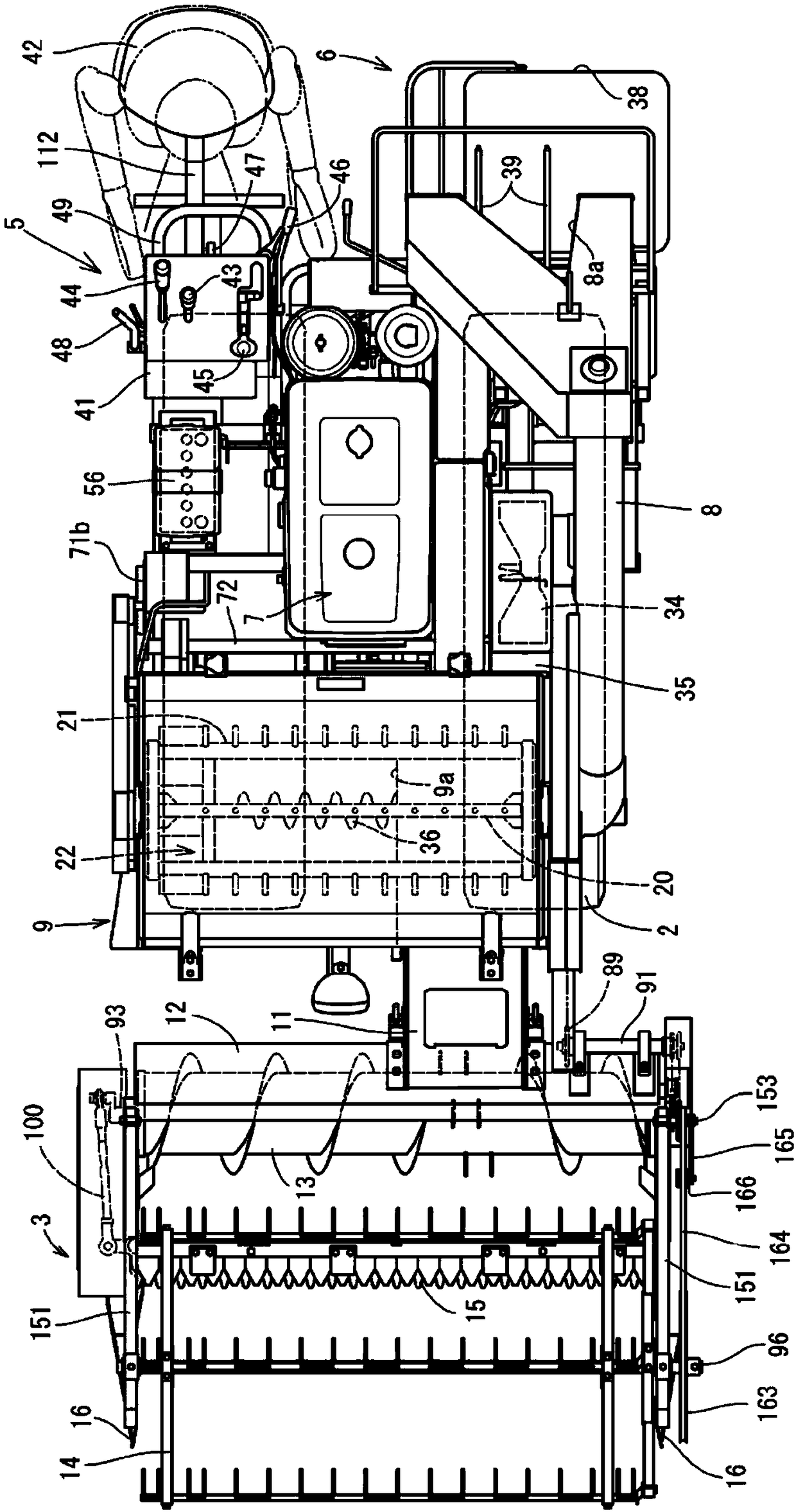

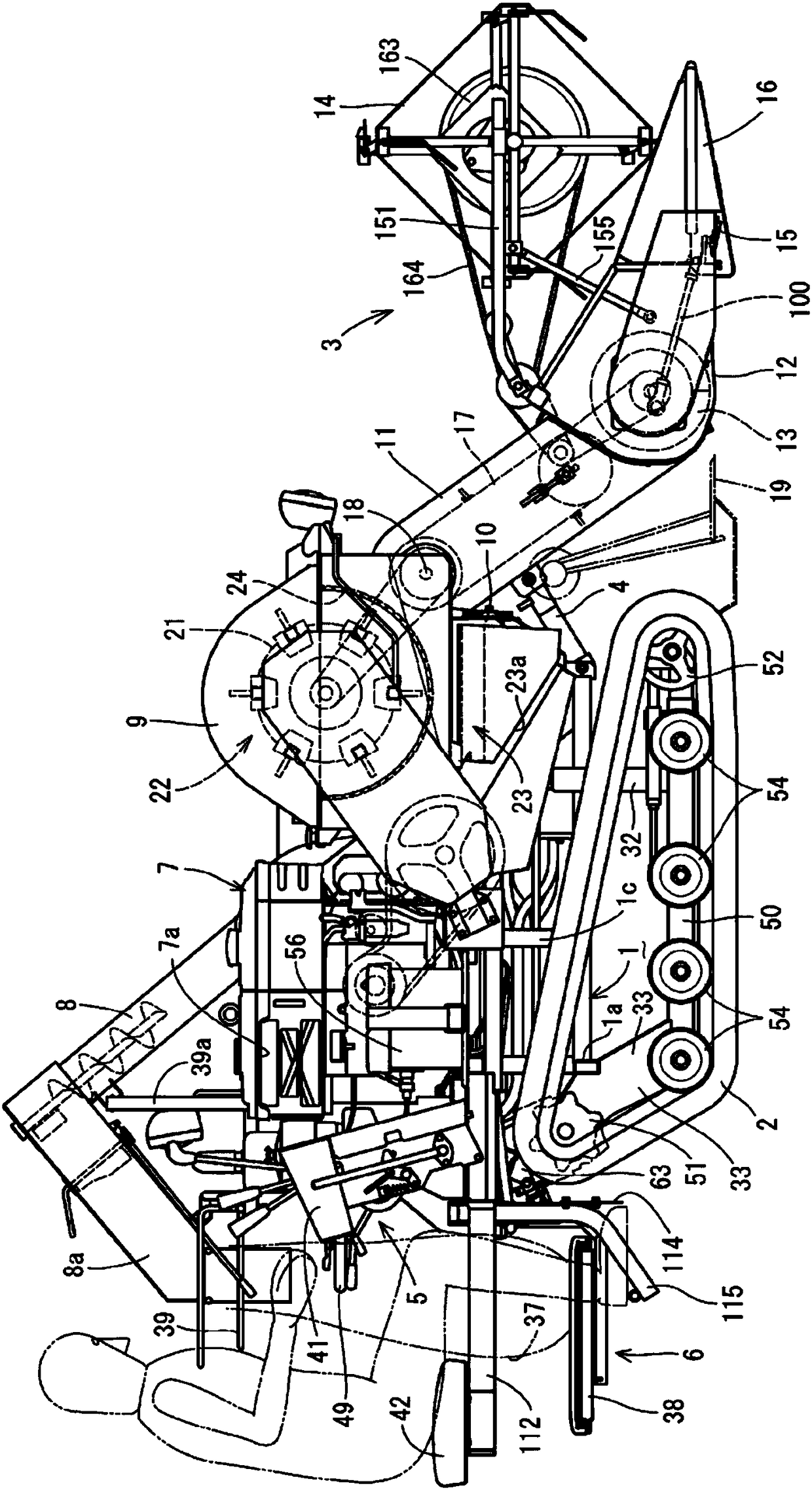

[0091] Below, according to the accompanying drawing ( Figure 1 to Figure 44 ) to describe embodiments that make the present invention real. First, refer to Figure 1 to Figure 10 The general structure of a conventional combine harvester will be described. In addition, in the following description, the left side is only called the left side toward the advancing direction of the traveling body 1, and similarly, the right side is simply called the right side toward the advancing direction.

[0092] Such as Figure 1 to Figure 10 As shown, the common type combine harvester of embodiment is equipped with the traveling body 1 supported by the right and left pair of crawlers 2 made of the rubber crawler which is a traveling part. The reaping part 3 is installed on the front part of the traveling body 1 in a manner capable of lifting adjustment by means of a single-acting lifting hydraulic cylinder 4, and the reaping part 3 reaps and takes in uncut ears such as rice (or wheat) st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com