Engine assembly bracket

A technology for assembling brackets and engines, applied in the direction of engine components, machines/engines, assembly machines, etc., can solve problems such as deformation, difficult modules, and unpredictable fixed positions of modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

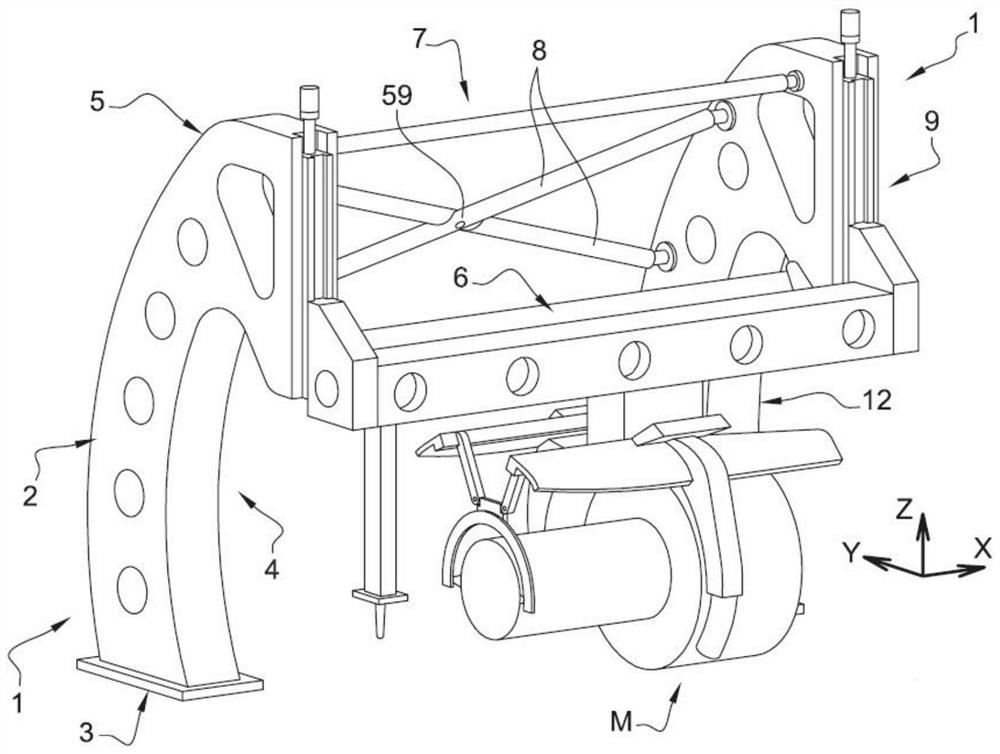

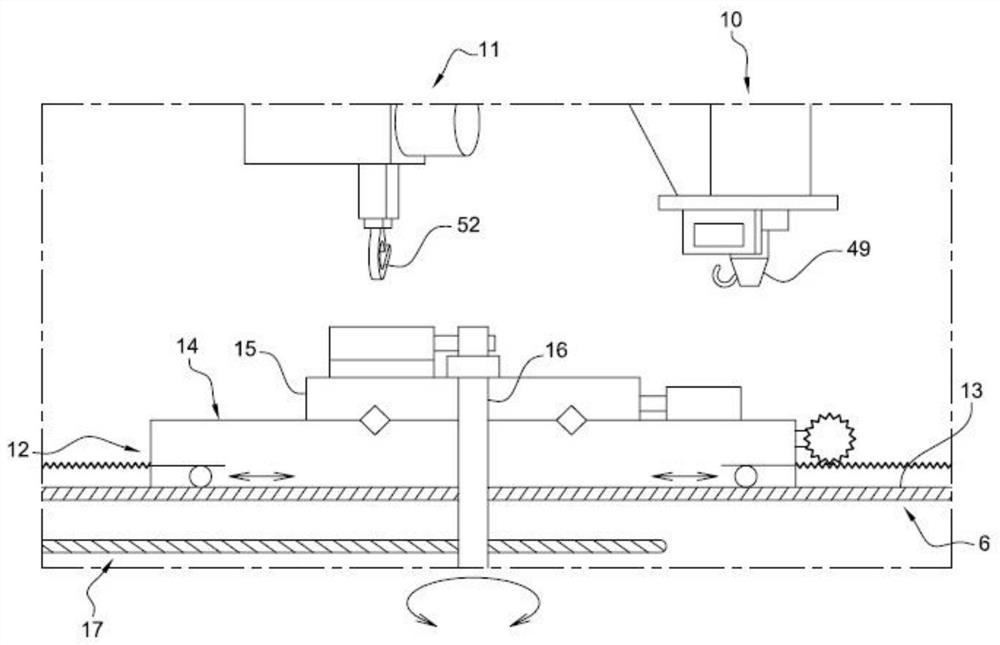

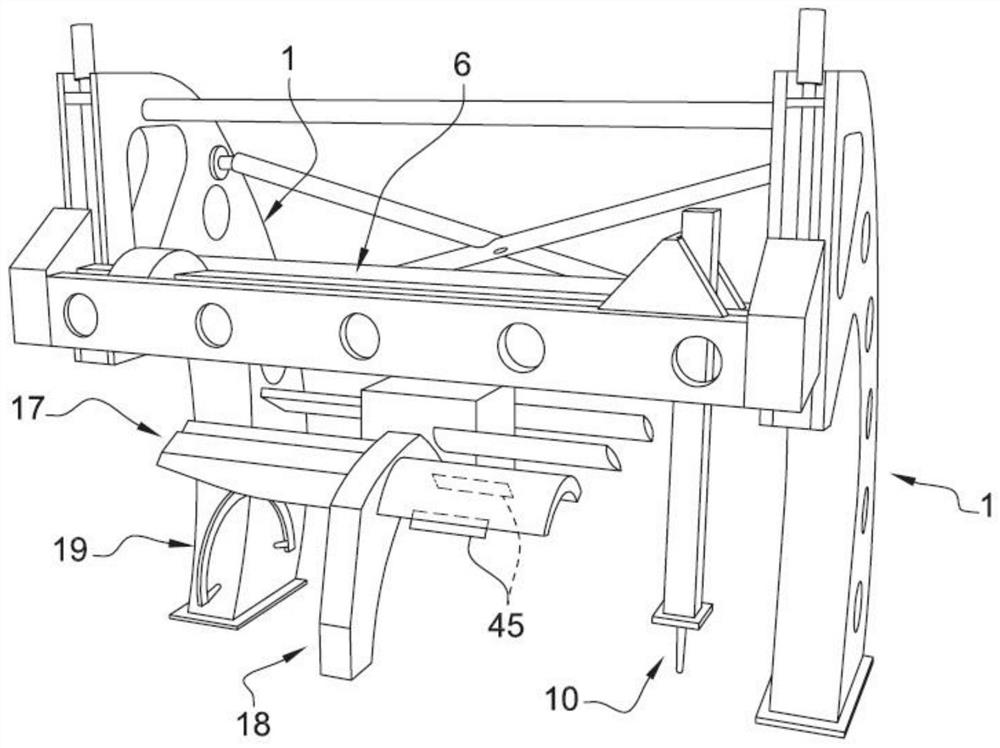

[0030] First refer to figure 1 . The support consists of two similar uprights 1, parallel and substantially vertical, each upright 2 comprising a riser 2 erected from feet 3 on a frame fixed to the ground, inclined away from longitudinal beams 6 for Supports the motor M, which will be described later, in the direction of ascent, over at least a part of its height; the riser 2 also has a curved portion, the concave surface 4 of which is directed towards the motor M assembled on the support, and has an upper arched bend 5 , the upper arched curved portion 5 extends between the rising portion 2 and the vertical surface bearing means for connecting the horizontal beam 6 . This column 1 shape is called a swan neck shape and has a pleasing appearance while providing a simplified cantilever, appropriate rigidity and a small footprint, which is useful for working around the engine and bringing the gear and modules to be installed from various places Provides a lot of freedom. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com