Inspection method, inspection device and manufacturing method of intermittent connection type optical fiber ribbon

An inspection method and technology of optical fiber ribbons, which are used in measuring devices, testing of machine/structural components, testing optical fibers/optical waveguide equipment, etc., can solve the problems of laser sensor configuration (difficulty in position adjustment, etc., and achieve the effect of high-precision inspection)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0039]

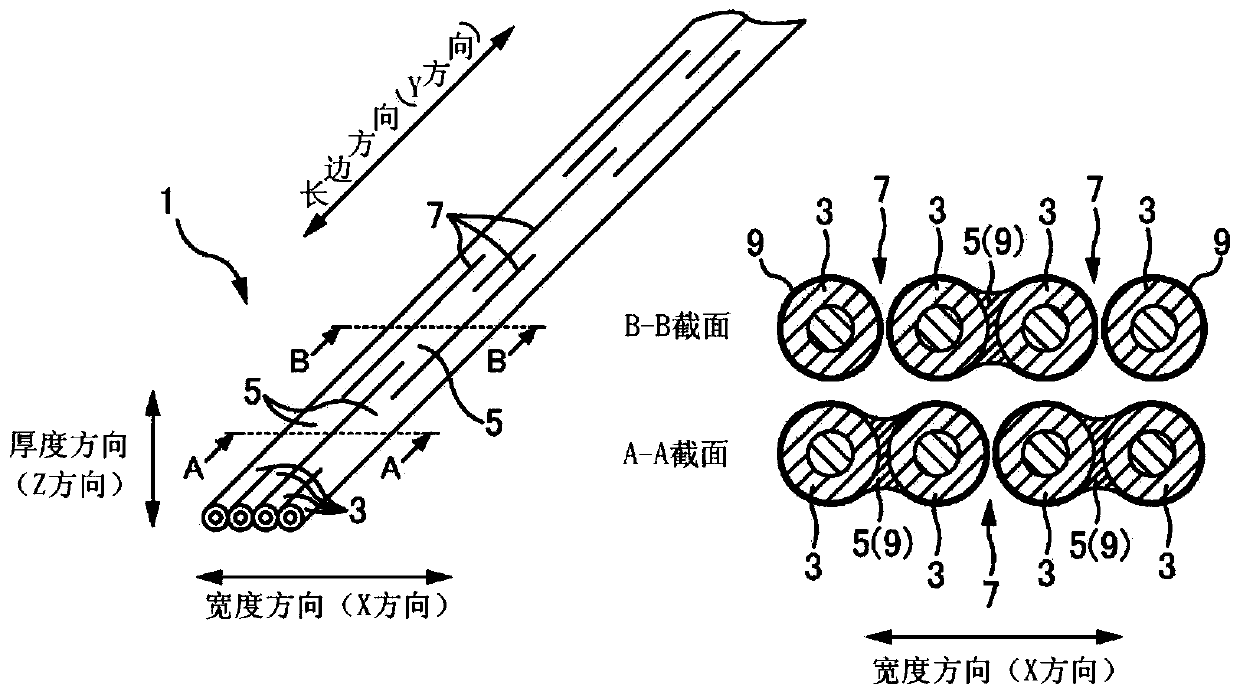

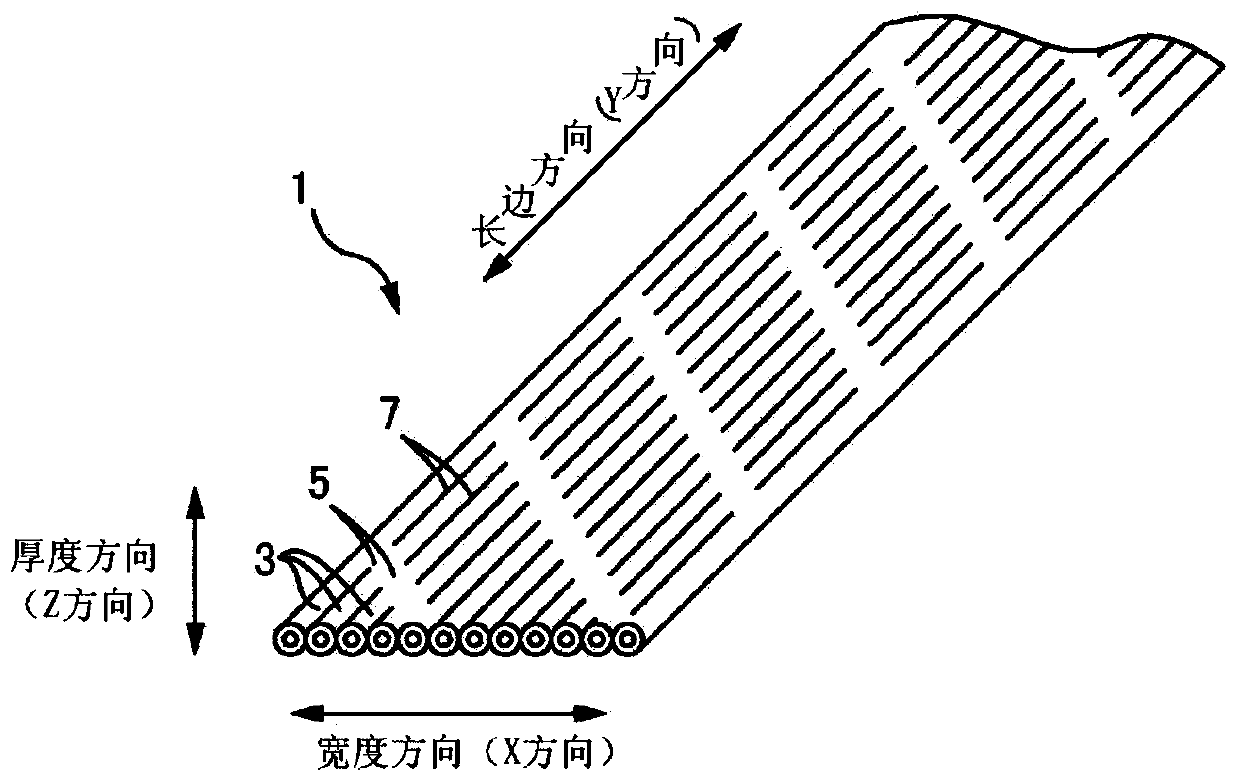

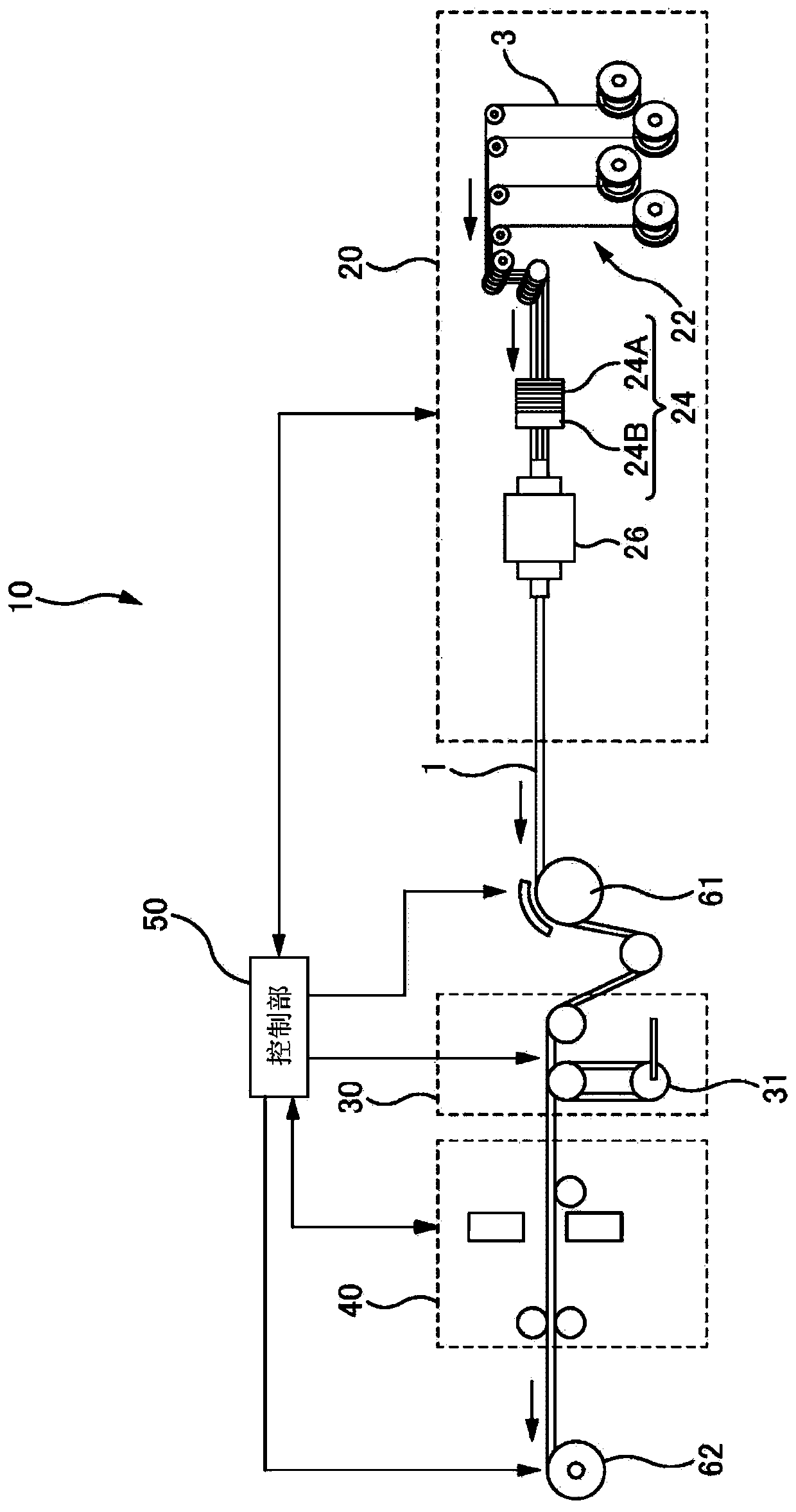

[0040] Figure 1A It is an explanatory diagram of a 4-core intermittent connection type optical fiber ribbon 1 . Figure 1A The right figure is the A-A or B-B sectional view of the perspective view on the left. Figure 1B It is an explanatory diagram of a 12-core intermittent connection type optical fiber ribbon 1 .

[0041] In the description below, if Figure 1A The directions are defined as shown. That is, the direction parallel to the optical fibers 3 constituting the optical fiber ribbon 1 is referred to as the "longitudinal direction". In addition, the direction in which the plurality of optical fibers 3 constituting the optical fiber ribbon 1 is arranged is referred to as a "width direction". In addition, the direction perpendicular to the ribbon surface of the optical fiber ribbon 1 is referred to as "thickness direction".

[0042] The intermittent connection type optical fiber ribbon 1 is an optical fiber ribbon 1 in which a plurality of optical fibers 3...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap