Industrial robot

An industrial and robotic technology, applied in manipulators, scientific instruments, semiconductor/solid-state device manufacturing, etc., can solve the problems of lower resonance frequency, insufficient rigidity of the hand fork, high cost, etc., so as to suppress the generation of defective products and improve the actual The effect of the job rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The composition of the present invention will be described in detail below with reference to the preferred embodiments shown in the accompanying drawings.

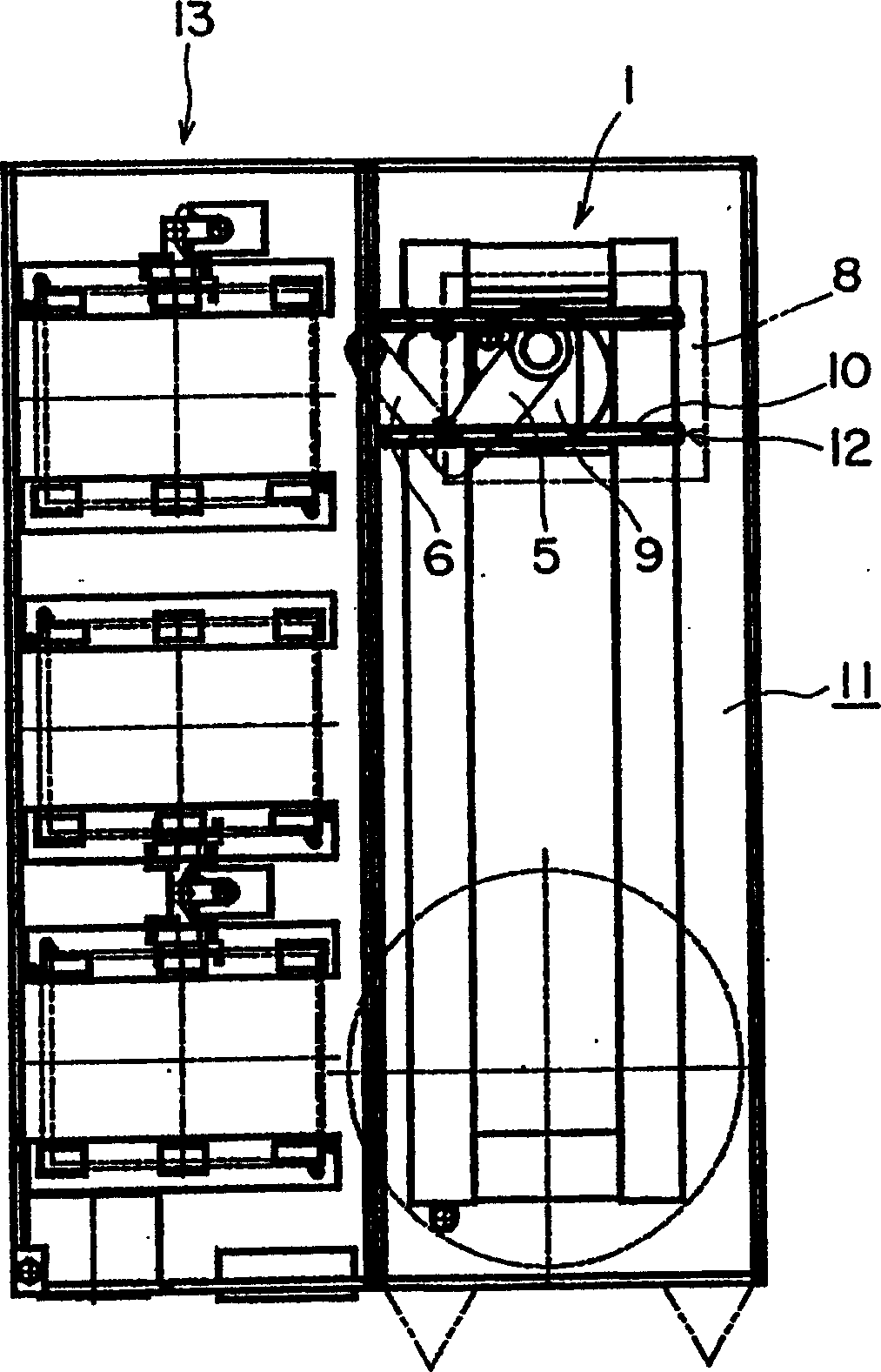

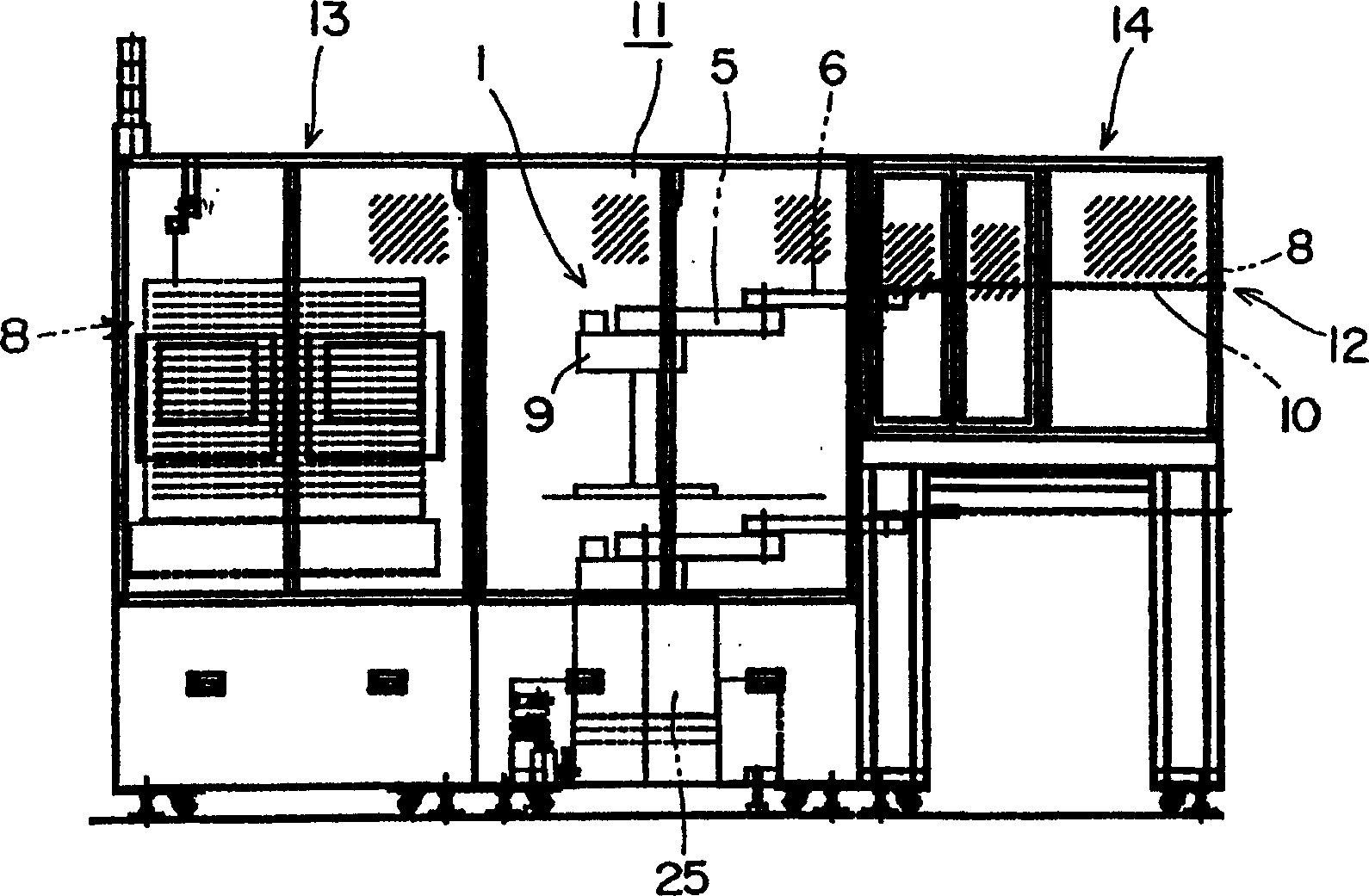

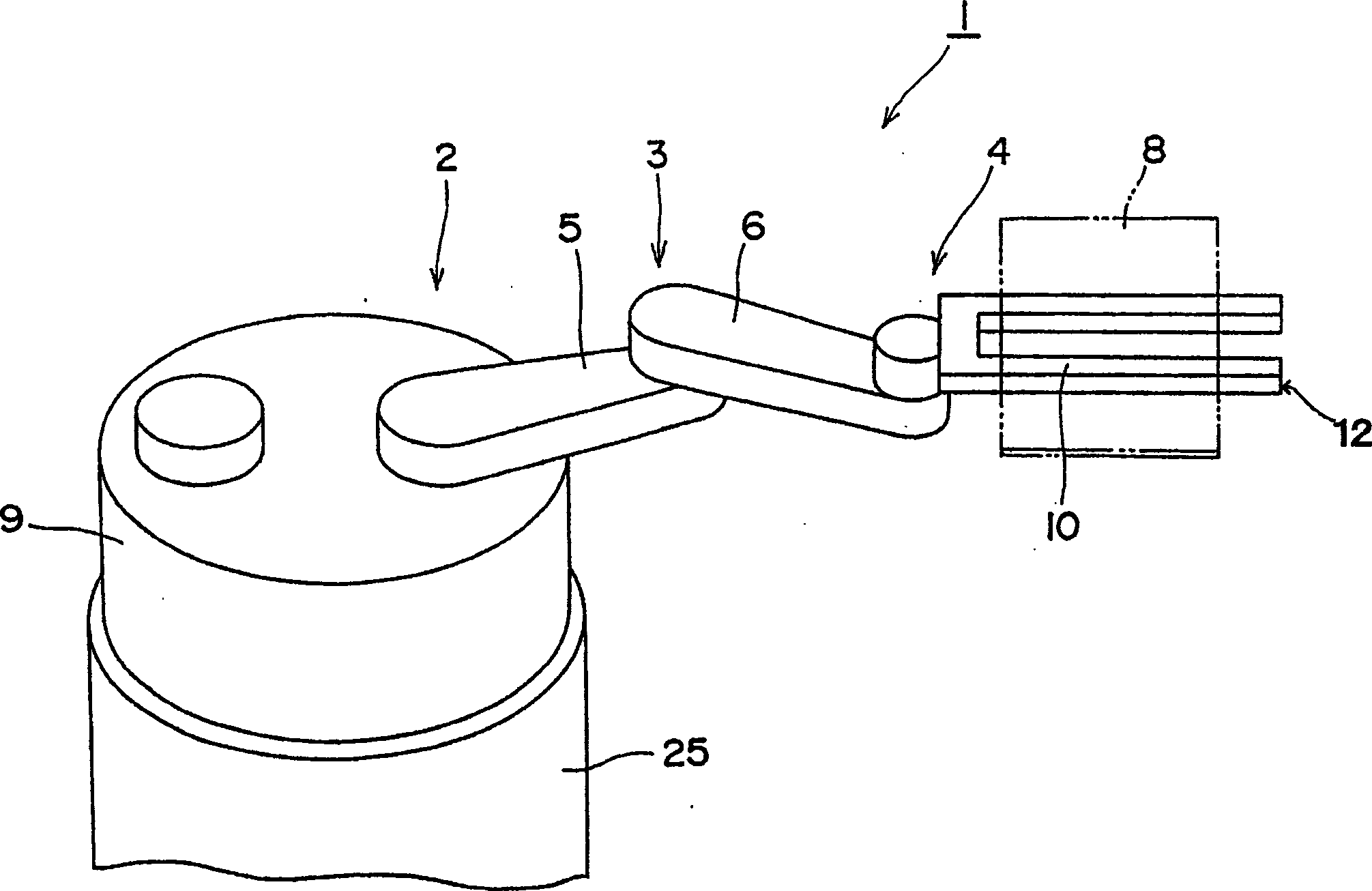

[0050] Figure 1 to Figure 5 Embodiment 1 of the industrial robot 1 of the present invention is shown. This industrial robot 1 performs operations such as assembly, processing, and transportation in the clean space 11 . Further, a particle counter for measuring the cleanliness in the clean space 11 is provided on the hand 10 of the industrial robot 1 . Therefore, the amount of particles near workpieces 8 such as semiconductor wafers and liquid crystal panels placed on the hand 10 can be measured by the particle counter, so accurate inspection can be performed.

[0051] This industrial robot 1 is, for example, an arm drive device that transports the workpiece 8 from the cassette 13 to the manufacturing device 14 . These industrial robots 1, boxes 13, and manufacturing devices 14 are all installed in a clean room 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com