Battery screen printing quality detecting method based on block template matching

A quality inspection method and template matching technology, applied in sorting, measuring devices, analyzing materials, etc., can solve problems such as high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

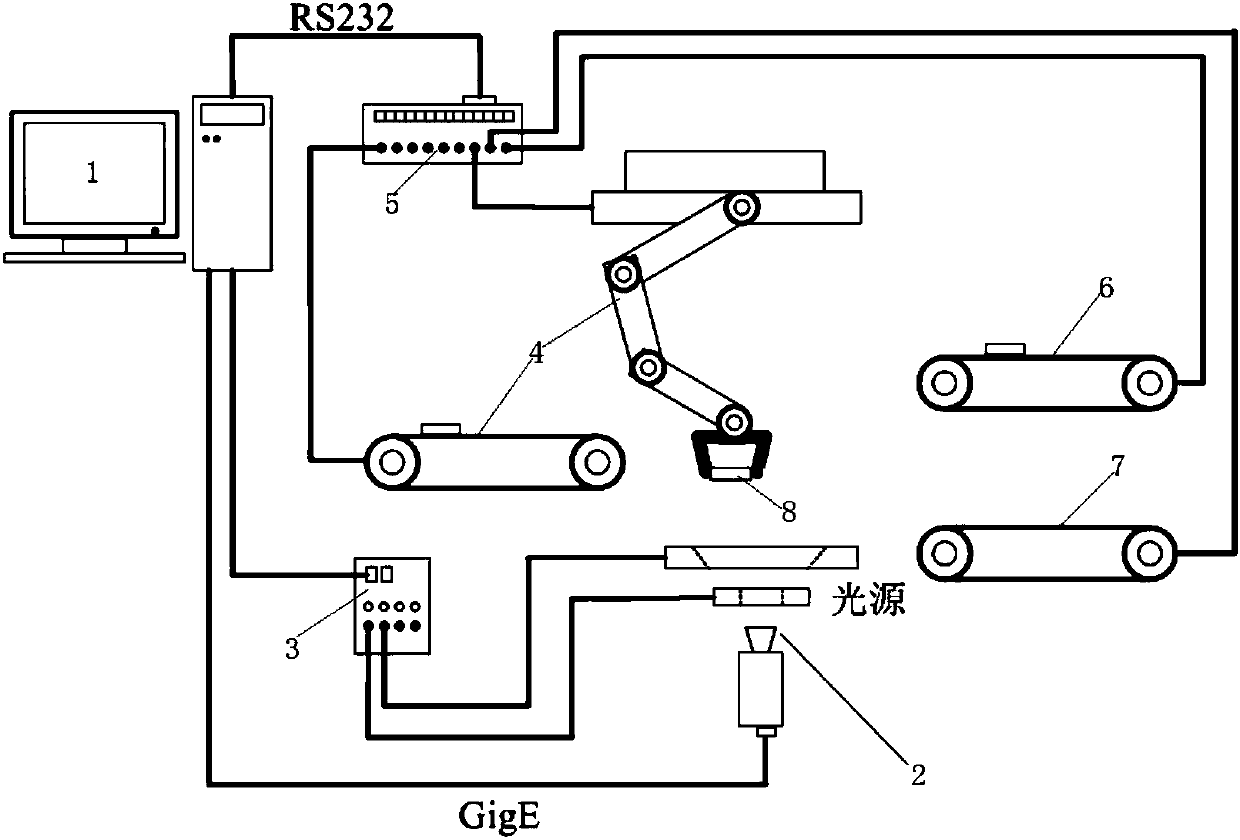

Method used

Image

Examples

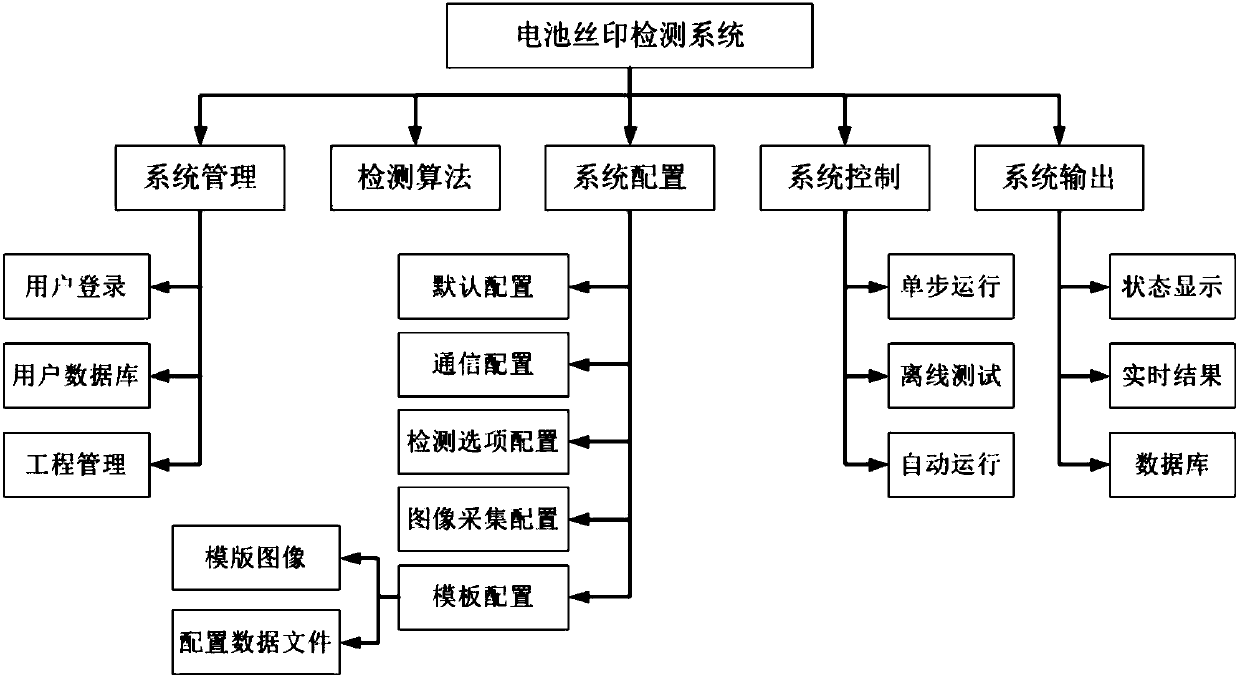

Embodiment Construction

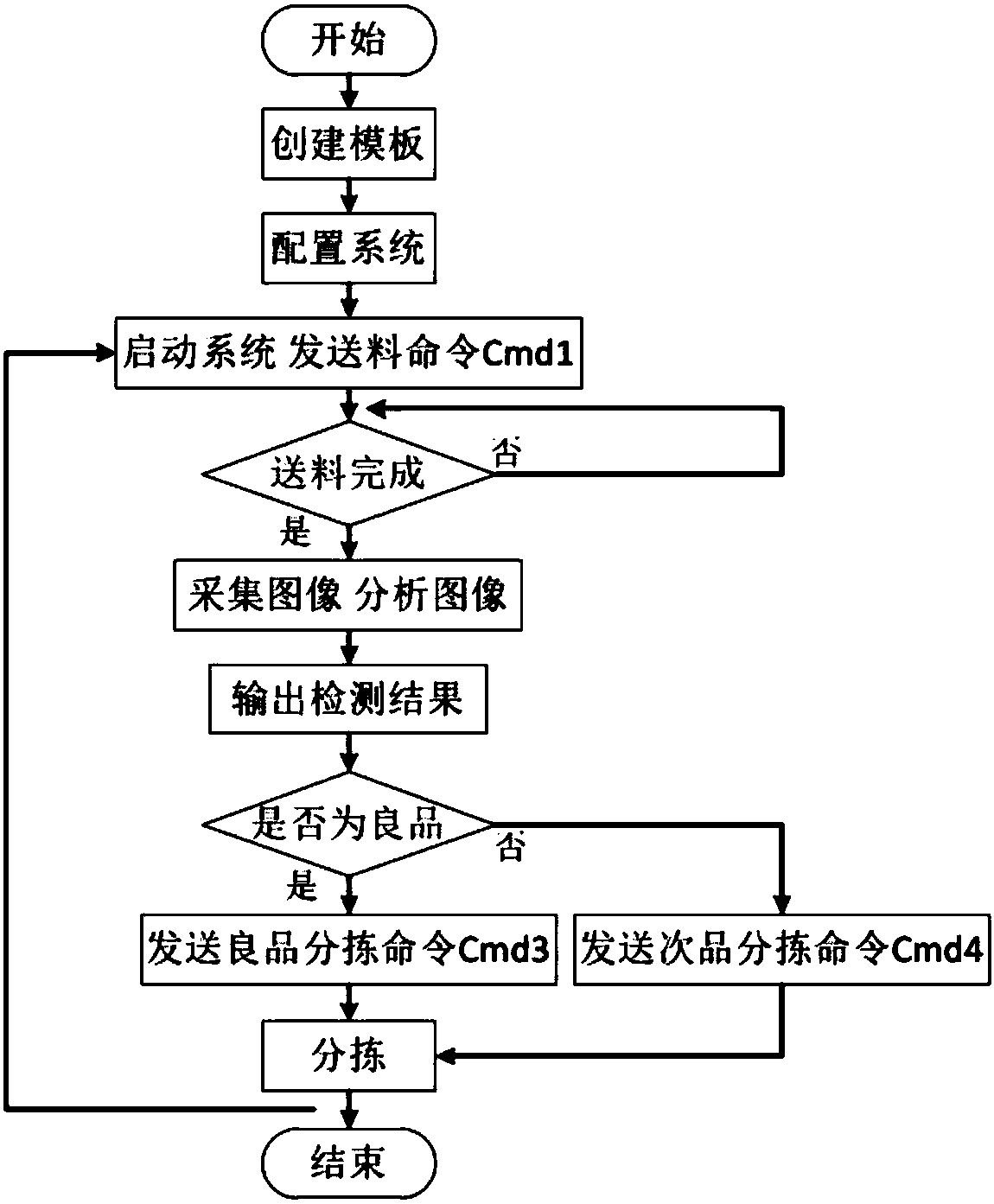

[0072] The detection method proposed by the present invention is a detection method based on template matching, so the system needs a template before the battery screen printing detection. Because there are many types and models of batteries, the creation of detection templates needs to be specific to specific models. The creation of the template includes two aspects, that is, the creation of the template image and the creation of the configuration file. The color difference of each part in the global image can be obtained by using the color difference detection algorithm. At the same time, it can also be averaged to observe the global chromatic aberration.

[0073] see Figure 8 , the creation of the template image:

[0074] Select a flawless battery to collect its image, and then use the automatic threshold method on the image to separate the battery from the background, and then perform tilt correction and cropping on the battery image. All printed content must be includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com