Grinding device for large stone plates

A slate and large-scale technology, applied in the field of large-scale slate grinding devices, can solve problems affecting product quality, changes in slate physical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the specific embodiments in the accompanying drawings.

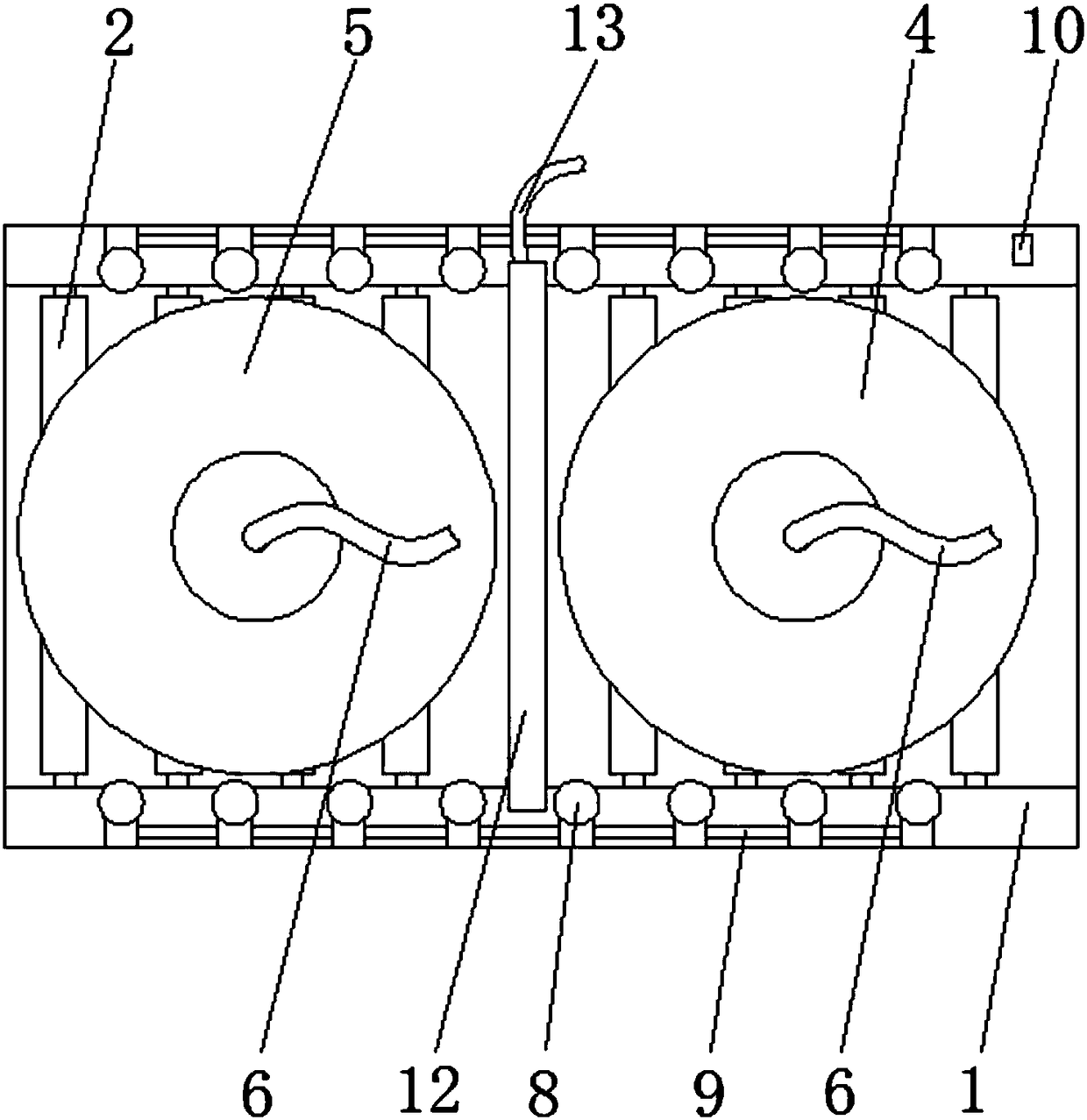

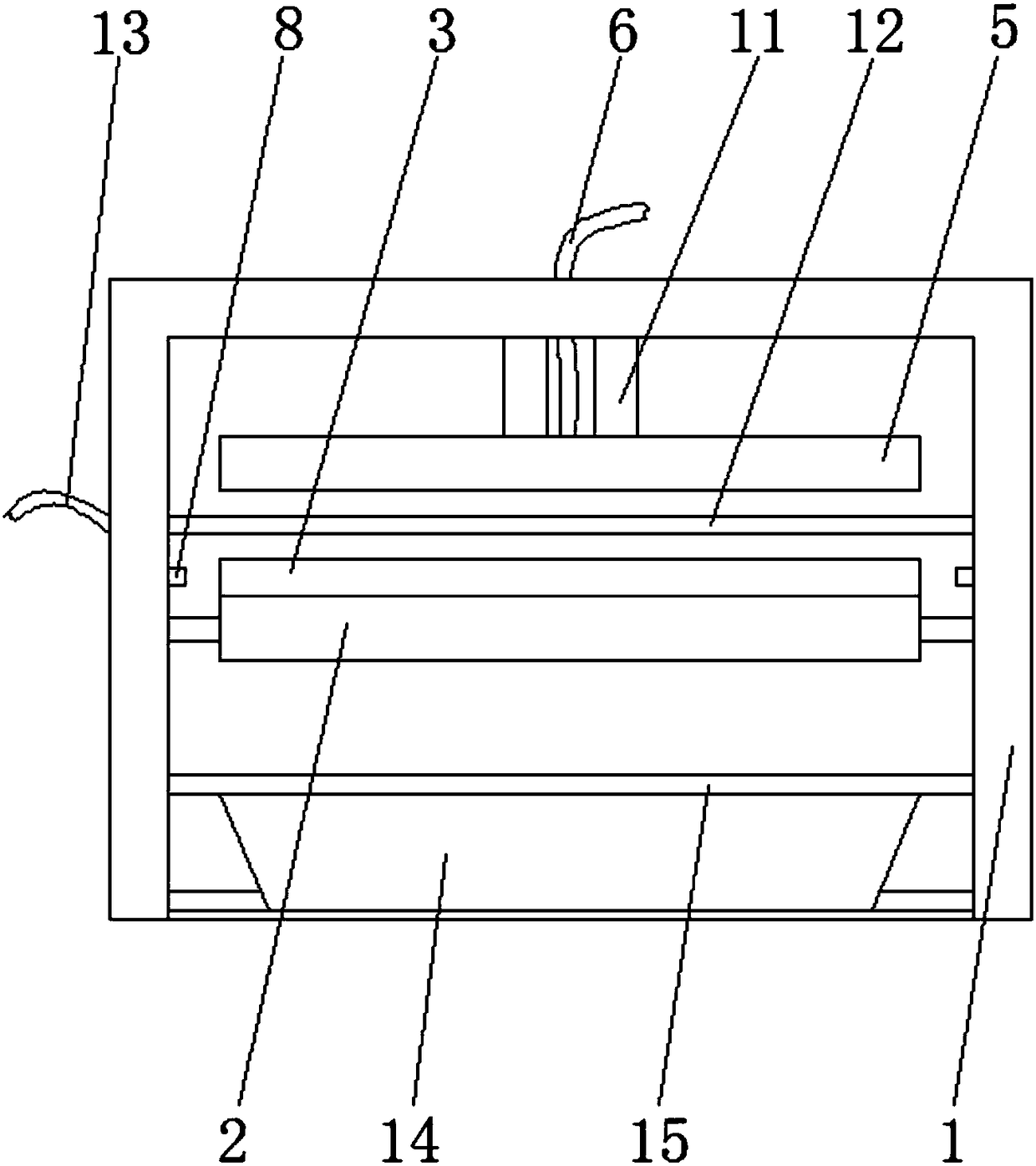

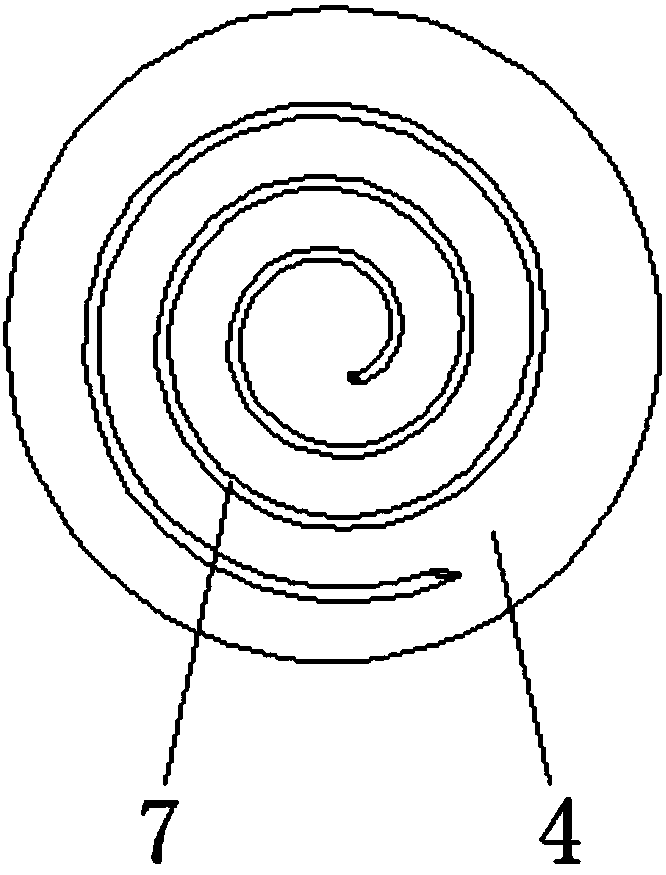

[0020] see Figure 1-3 , a grinding device for large-scale stone slabs of the present invention includes a frame 1, and a horizontally arranged conveyor roller table 2 is arranged in the rack 1 for conveying large-scale stone slabs. There is a guide assembly for positioning and guiding the stone plate 3 to prevent the stone plate 3 from shaking during the grinding process. The frame 1 above the conveying roller table 2 is provided with a horizontal juxtaposition of the rough grinding head 4 and the fine grinding head 5. The stone plate 3 undergoes two processes of rough grinding and fine grinding, so as to avoid the problem of changing the physical properties of the stone plate 3 due to the excessive grinding allowance of one grinding, thereby improving the grinding accuracy. A cleaning component for cleaning the surface of the slate 3 is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com