Diamond tool bit feeding system

A technology of diamond cutter head and feeding system, which is applied in the field of diamond cutter head feeding system and material transportation, which can solve the problems of affecting the discharge speed, jamming, vibration amplitude reduction, etc., and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

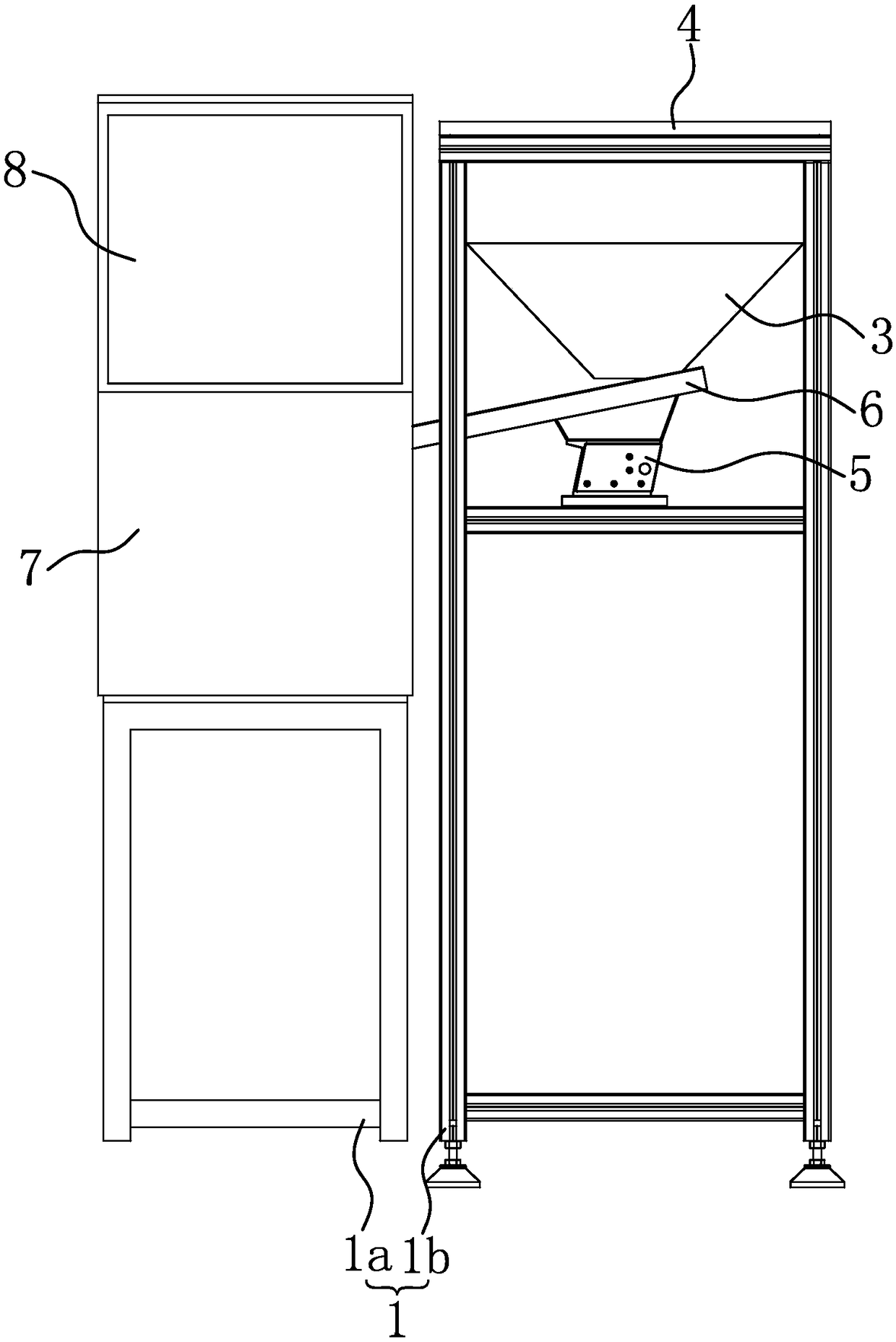

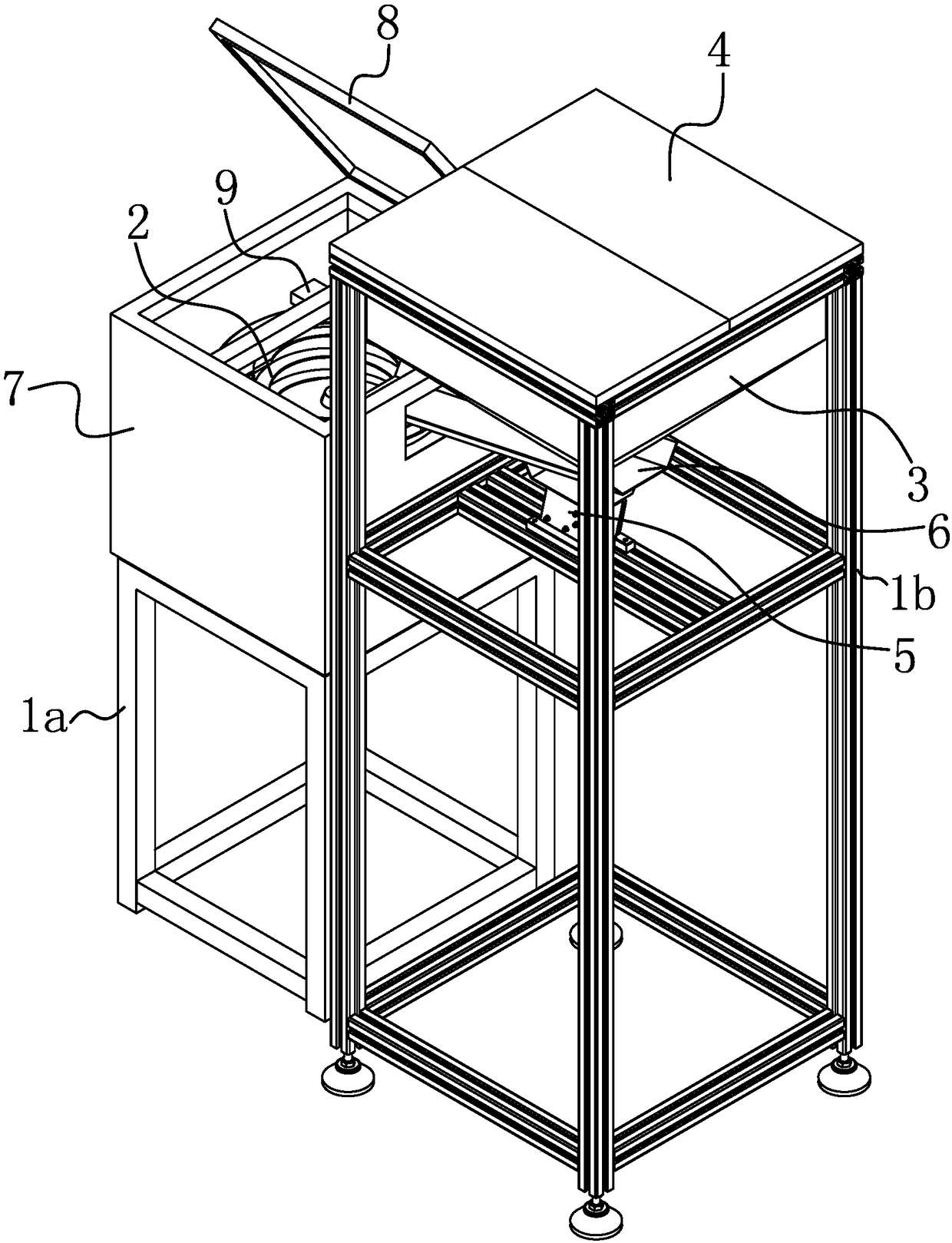

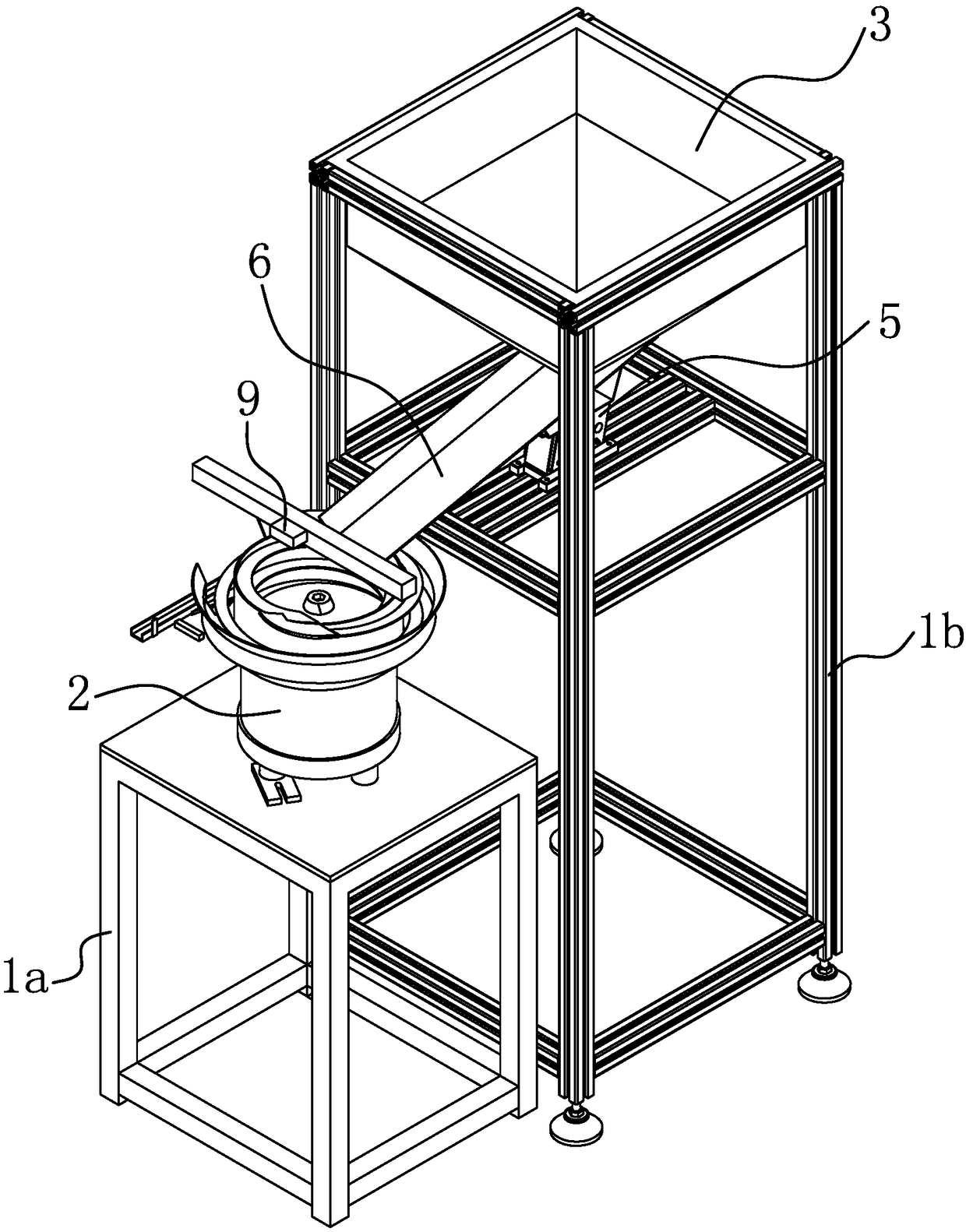

[0019] Such as Figure 1 to Figure 3 As shown, the diamond cutter head feeding system includes a support 1, a vibrating plate 2, a storage bin 3, a control mechanism and a control circuit.

[0020] The support 1 includes a vibration plate support 1a and a storage bin support 1b, the vibration plate 2 is installed on the vibration plate support 1a, and the storage bin 3 is installed on the storage bin support 1b. The storage bin 3 is located above the vibration plate 2, and the bottom of the storage bin 3 has a discharge port. The vibrating plate support 1a and the storage bin support 1b are independent of each other, and the storage bin support 1b is located on one side of the vibrating plate support 1a. This structure is convenient for manufacturing and avoids vibration of the vibrating plate 2 to cause the storage bin 3 to vibrate, thereby reducing noise generation quantity. The upper port of the storage bin 3 is covered with a cover plate 4 to prevent sundries from fallin...

Embodiment 2

[0026] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be described redundantly, only the differences will be described, and the differences lie in the structure of the control mechanism: Figure 4 As shown, the control mechanism includes a conveyor belt 10, and the inside of the conveyor belt 10 is provided with a driving wheel 11 and a follower wheel. 11 a motor 12 connected by transmission, and the motor 12 is electrically connected with the control circuit. One end of the conveyor belt 10 is located directly below the discharge port, and the other end is located directly above the inner cavity of the vibration plate 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com