Coring drill suitable for asphalt road surface and coring machine

A technology for asphalt pavement and coring drills, which is applied to roads, drill bits, roads, etc., can solve the problems of shortening the service life of the coring drill, breaking the core sample, destroying the structural accuracy of the coring machine, etc., and achieves the effect of avoiding the expansion of the gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

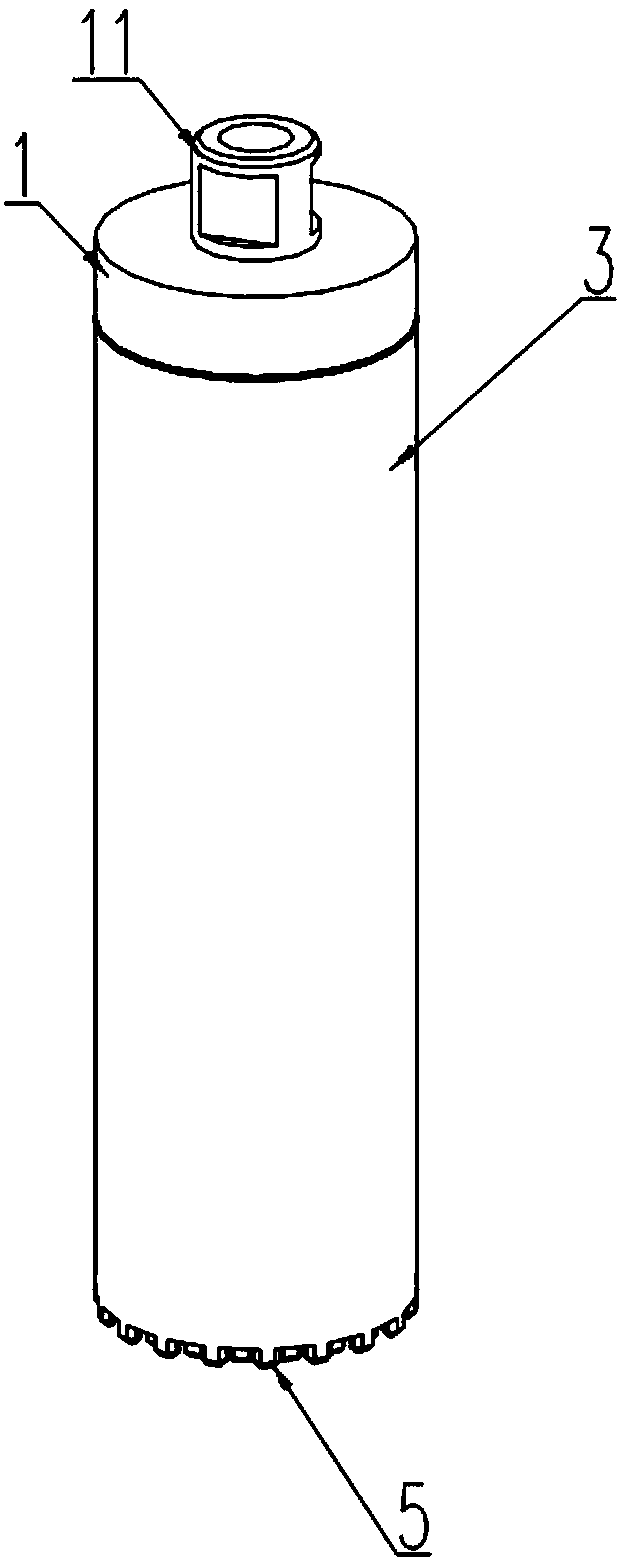

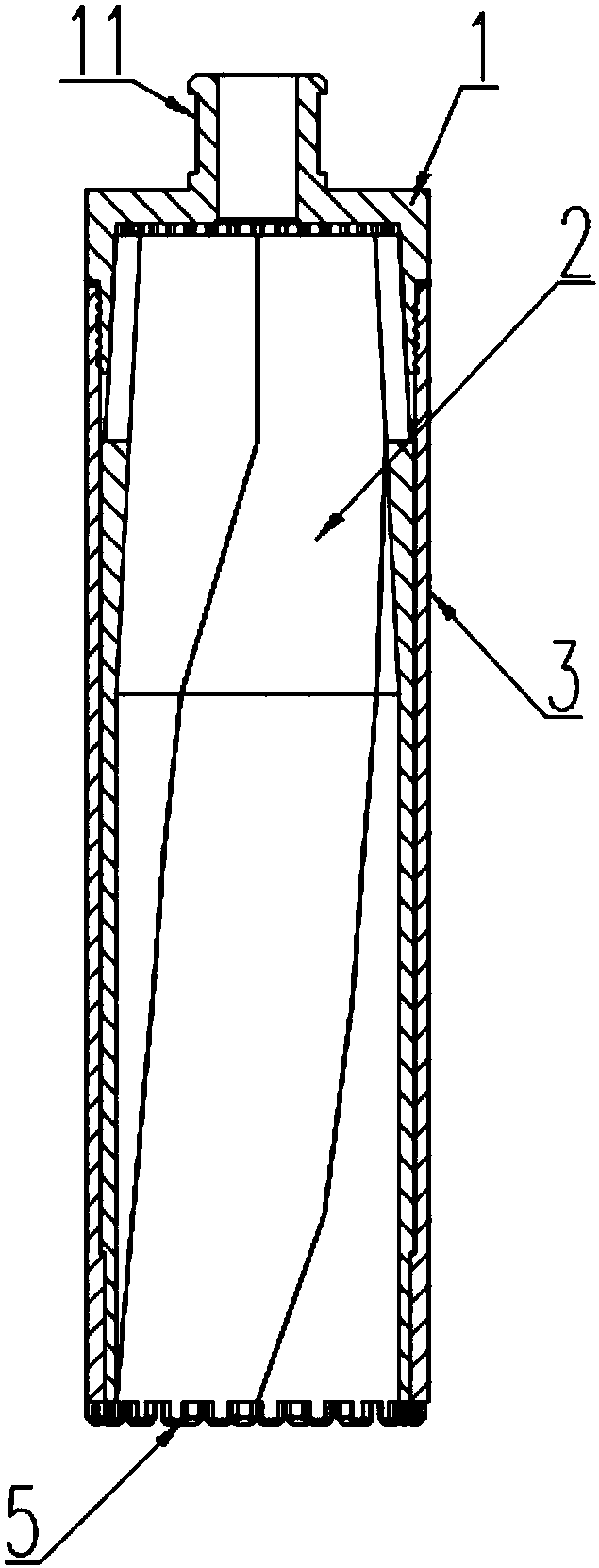

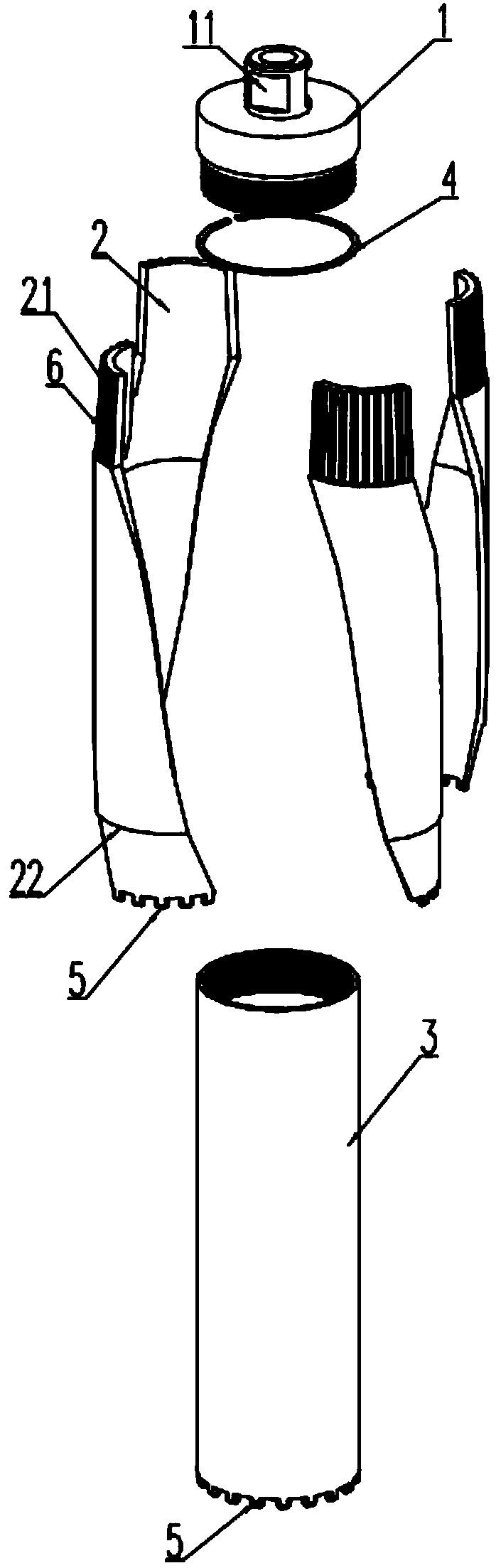

[0044] Such as Figure 1 to Figure 5 As shown, it is Embodiment 1 of the present invention. This embodiment provides a coring drill suitable for asphalt pavement, which is used to be installed on a coring machine for drilling and coring the asphalt pavement. This embodiment includes a drill handle 1 and a drill body, the drill handle 1 has a clamping portion 11 suitable for connecting with the main shaft of a coring machine; the drill body is cylindrical, connected with the drill handle 1, and the drill The end of the body away from the drill shank 1 is provided with several cutting teeth 5, and the cutting teeth 5 are suitable for circular motion following the drill body and cutting the road surface; the drill body includes a cylindrical liner, and the liner is composed of At least two bar-shaped drill pieces 2 with arc-shaped cross-sections are assembled. The central angle corresponding to any cross-section of any one of the drill pieces 2 is not greater than 180°. The drill...

Embodiment 2

[0056] This embodiment provides a coring machine. The lower end of the main shaft of the coring machine is equipped with the core drill provided in Embodiment 1. This embodiment relies on driving the core drill to rotate, and then splits the asphalt pavement.

[0057] Since the present embodiment is equipped with the coring drill provided in embodiment 1, it has all the advantages brought by the coring drill provided in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com