Linear Motion Units with Lifetime Monitoring

A linear motion and linear technology, applied in the direction of measuring devices, electrical devices, mechanical measuring devices, etc., can solve problems such as drift drama

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

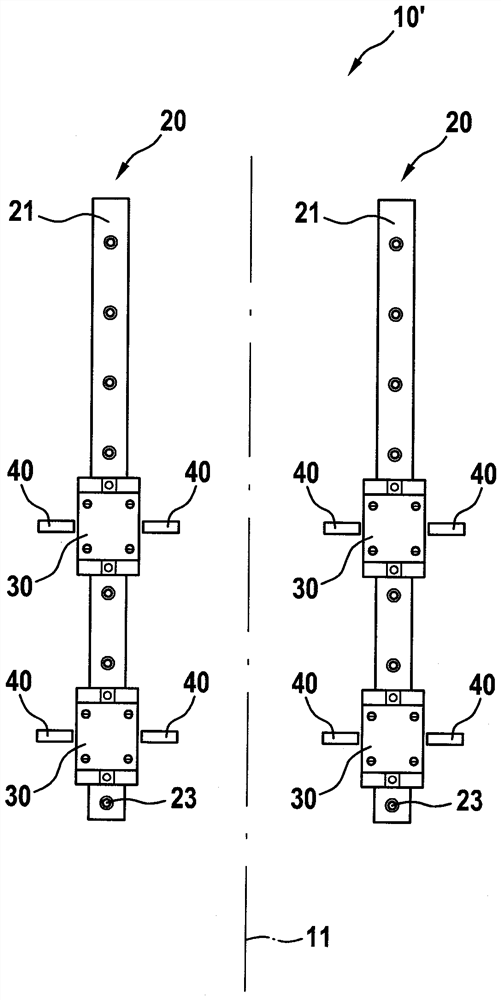

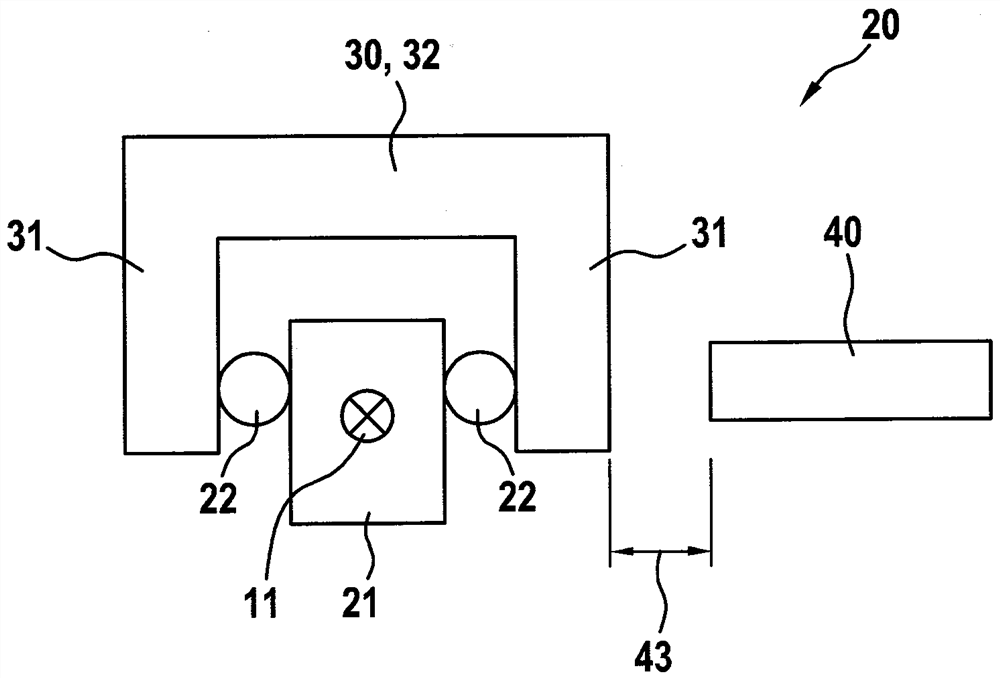

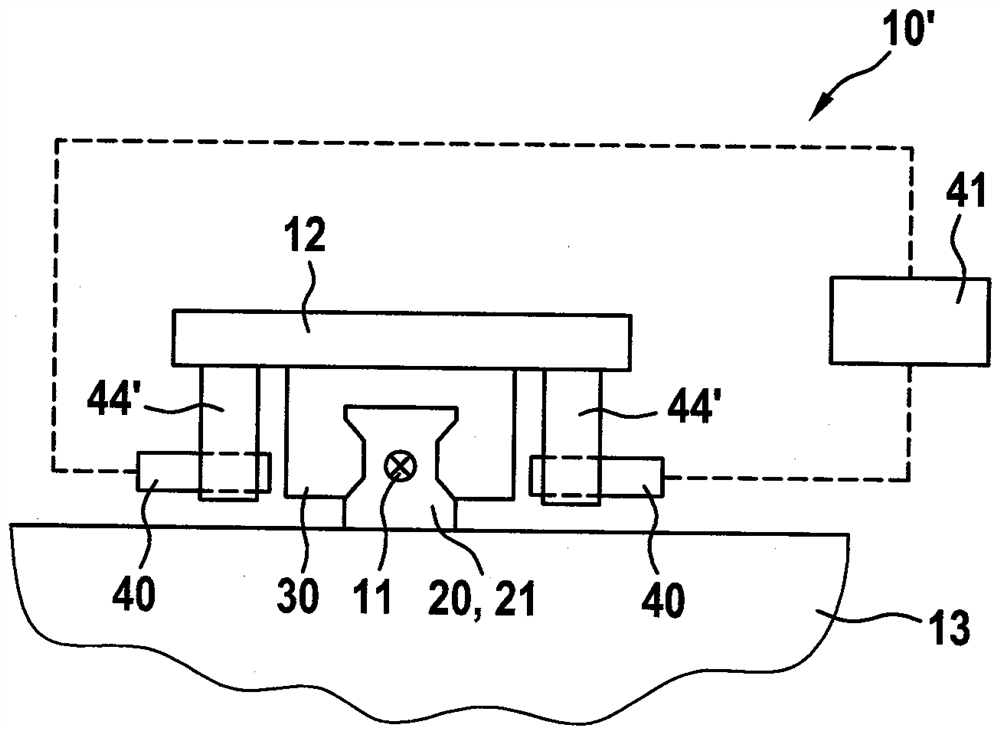

[0050] figure 1 A roughly schematic cross-section through a prestressed linear rolling guide 20 according to the first embodiment is shown. The linear rolling guide 20 has a guide rail 21 extending with a constant cross-sectional shape along a longitudinal axis 11 perpendicular to figure 1 The drawing plane orientation of . The guide rail 21 is preferably made of steel and is hardened in the region of the track for the rolling elements 22 . Currently, the rolling bodies 22 are designed as balls made of hardened steel, wherein cylindrical or barrel-shaped rolling bodies are also conceivable. Viewed in cross section, the guide carriage 30 is U-shaped. It has a fastening portion 32 from which two legs 31 project at right angles. fastening part 32 with workbench (in figure 2The label 12) is fixedly connected. The leg 31 surrounds the guide rail 21 , wherein the rolling bodies are arranged between the guide rail 21 and the leg 31 . Presently, two rows of bearing rolling bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com