Vibration reduction and noise reduction device with blocking type structure

A technology of vibration reduction and noise reduction, main structure, applied in the direction of springs/shock absorbers, spring components composed of several springs, springs, etc. Noise reduction, inability to meet rigid connection and other problems, achieve the effect of novel design method, flexible structure and shape, and scientific vibration reduction principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

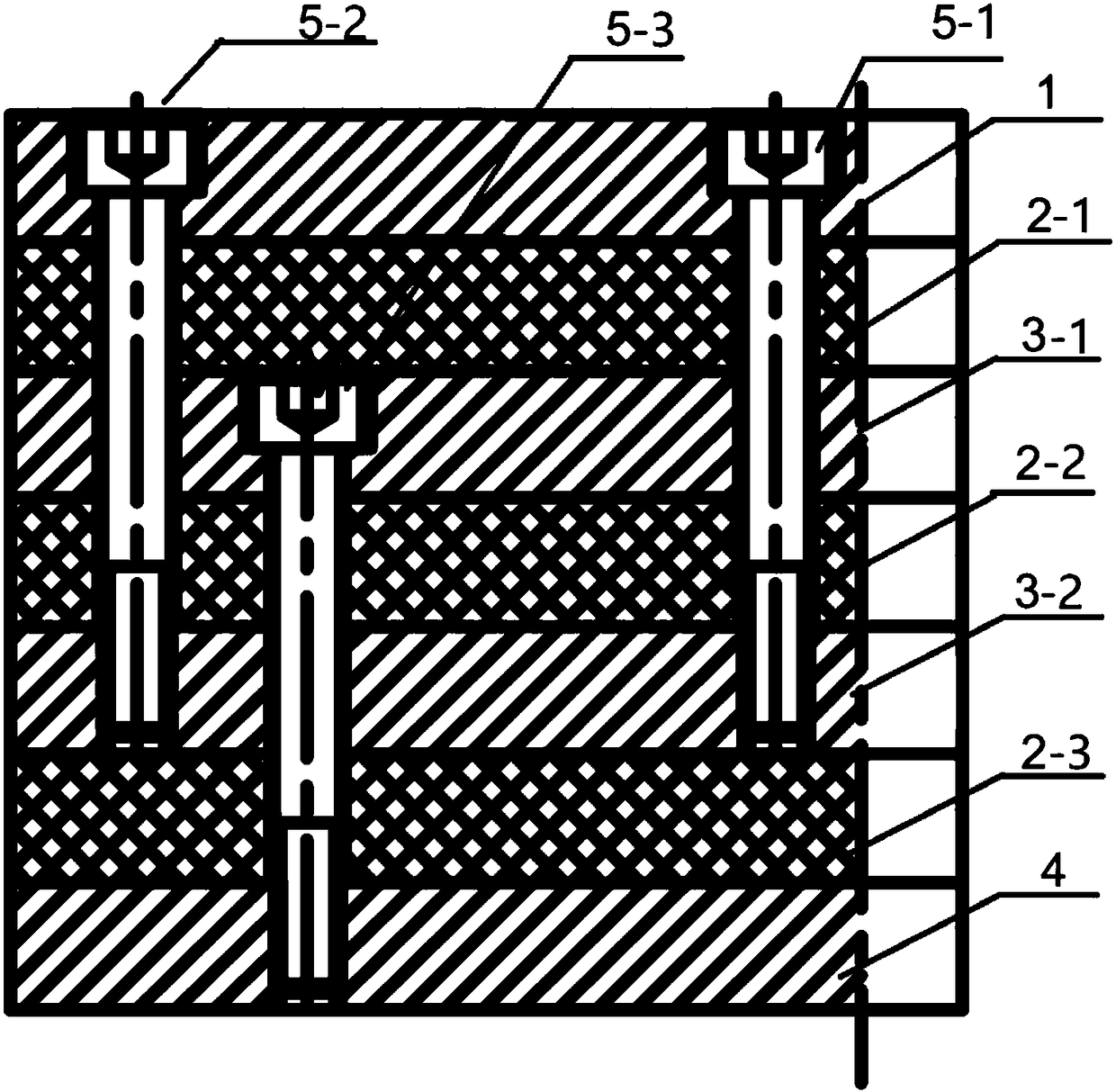

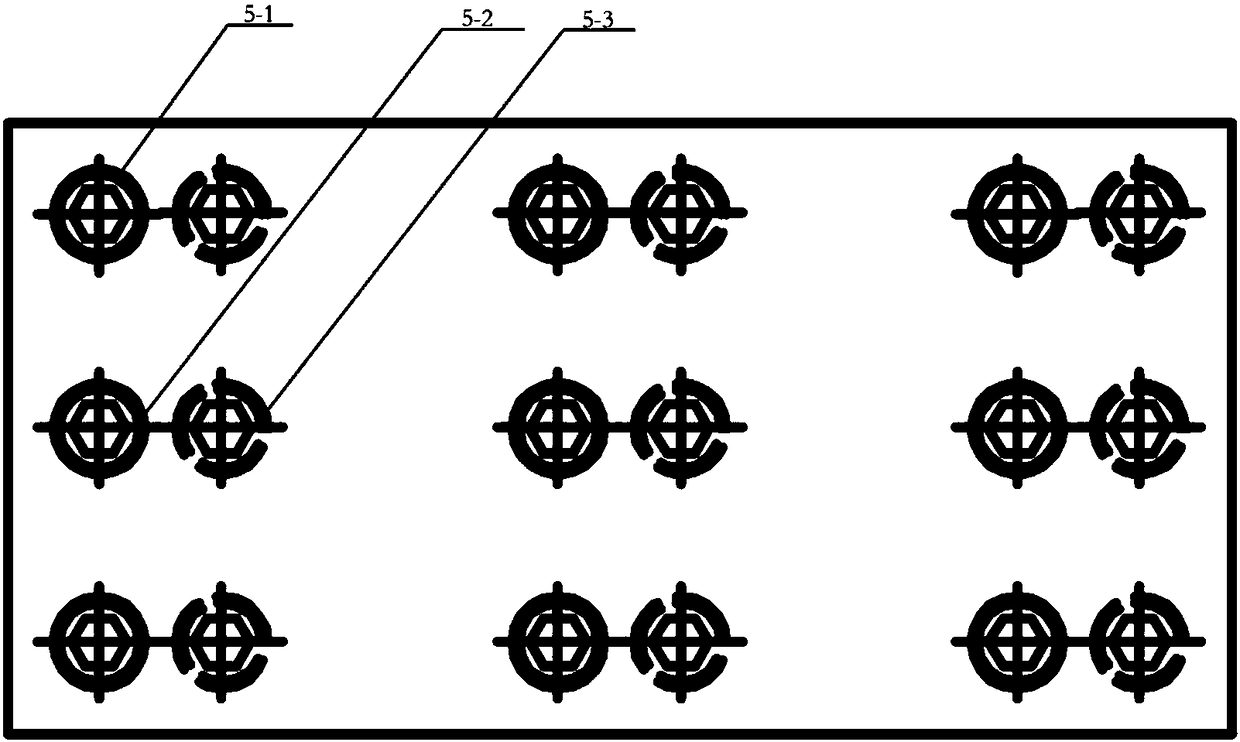

[0020] The vibration and noise reduction device with a blocking structure involved in this embodiment has a main structure design that can produce a variety of different structural expressions. Taking the vibration and noise reduction electromechanical equipment base with a blocking structure as an example, its main structure includes Top plate 1, first damping plate 2-1, second damping plate 2-2, third damping plate 2-3, first liner 3-1, second liner 3-2, base 4, first bolt 5 -1, the second bolt 5-2 and the third bolt 5-3 (see figure 1 and figure 2); according to the stacked arrangement order from top to bottom, it is top plate 1, first damping plate 2-1, first lining plate 3-1, second damping plate 2-2, second lining plate 3-2 and The third damping plate 2-3 is tightly reinforced layer by layer and fastened to the base 4 with the first bolt 5-1, the second bolt 5-2 and the third bolt 5-3 respectively, forming a complete rigid-flexible combination The blocking type vibrati...

Embodiment 2

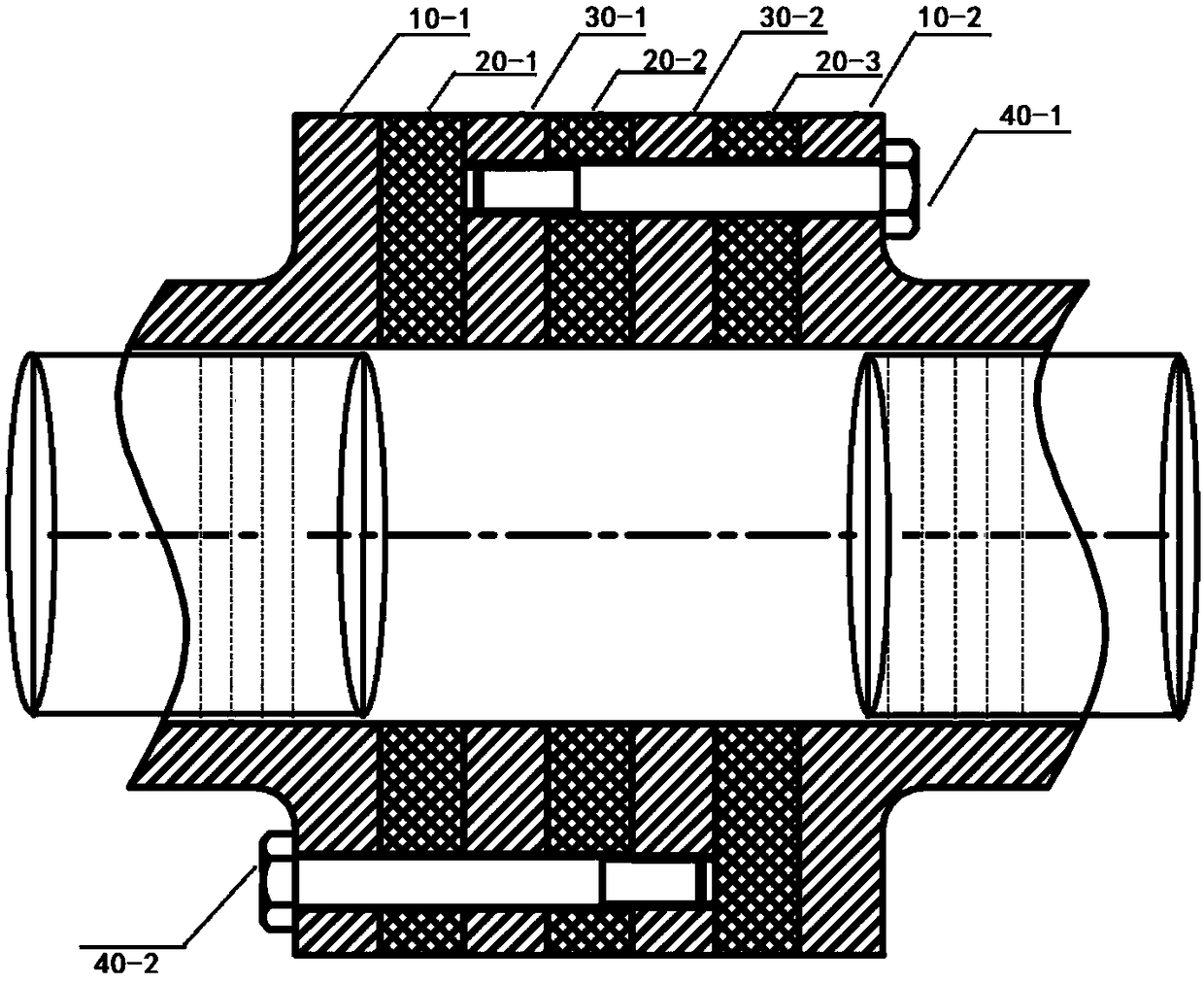

[0028] The vibration and noise reduction device with a blocking structure involved in this embodiment is suitable for technical fields such as ships, locomotives, building elevators, and aerospace; the middle position of the device described in Embodiment 1 is opened, and the top plate 1 and the base 4 As the two ends of the pipe flange, it is deformed into a special flange structure device (see image 3 and Figure 4 ), the selection of its structural principle and material is the same as the device in embodiment 1; the main structure includes a first base body 10-1, a second base body 10-2, a first damping plate 20-1, a second damping plate 20-2 , the third damping plate 20-3, the first lining plate 30-1, the second lining plate 30-2, the first bolt 40-1 and the second bolt 40-2; according to the stacked arrangement order from left to right, The first base body 10-1 is arranged on the far left side, and the first damping plate 20-1 is arranged on the right side of the first...

Embodiment 3

[0030] This embodiment takes the vibration-reducing and noise-reducing base of the blocking structure of the ship engine as the implementation plan, and further explains the technical solution of the present invention. According to the area of the ship's engine room and the area and weight of the bottom of the engine, the cost of setting up all or part of the engine room floor is determined. The vibration-damping raft described in the invention, the raft can be a single structure or a multi-body structure; due to the large size and heavy tonnage of the ship engine, the optimal solution is to set the engine room floor as a whole for vibration reduction Noise-reducing raft seats, and choose a multi-body structure to facilitate manufacturing, installation and maintenance. The damping part is a superimposed structure of rubber cushion air cushion and magnetic cushion. The base body and the top plate are shared. Multiple mechanical devices are installed on the top plate. Air-condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com