Composite laminated battery core manufacturing control method, composite laminated battery core and lithium battery

A control method and stacking technology, which is applied to lithium batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve the problems of cell alignment changes, unfixed folding position of the first pole piece, and stacked batteries that do not meet product quality. core and other issues, to achieve high alignment, improve folding quality and folding efficiency, and improve quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

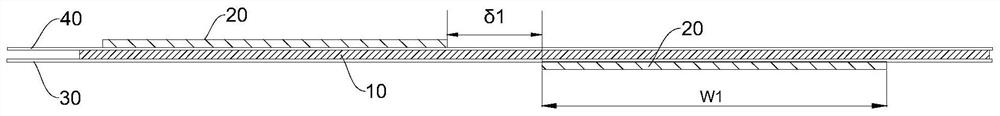

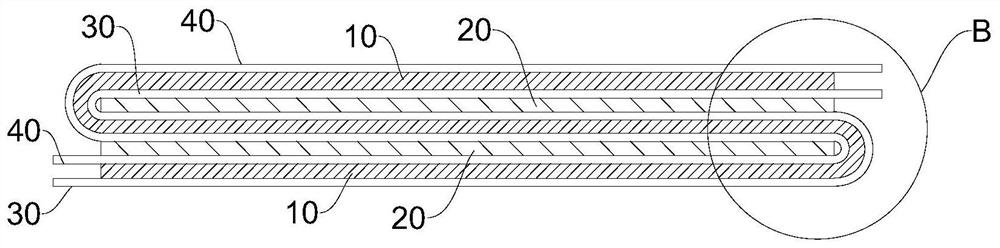

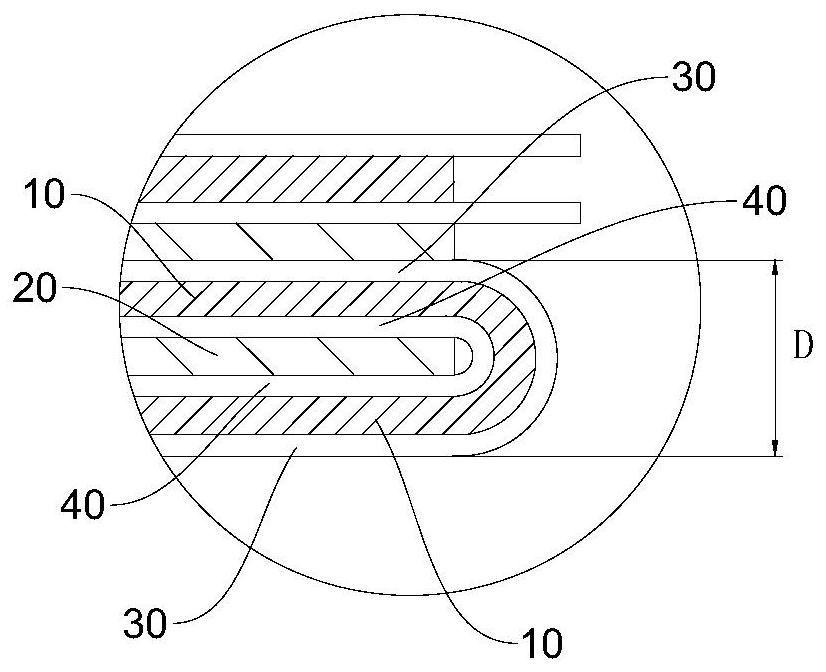

[0050] Please refer to figure 1, this embodiment provides a composite laminated cell production control method, which is applied to the following composite laminated cell, the composite laminated cell includes a first diaphragm 30, a second diaphragm 40, a first pole piece 10 and The second pole piece 20. Wherein, before stacking, the first pole piece 10 is continuously arranged between the first diaphragm 30 and the second diaphragm 40, and a plurality of second pole pieces 20 are alternately arranged between the first diaphragm 30 and the second diaphragm 40 away from the first diaphragm 30 and the second diaphragm 40. One side of the pole piece 10, for example, if the first second pole piece 20 is arranged on the side of the first diaphragm 30 away from the first pole piece 10, then the second second pole piece 20 is arranged on the side away from the second diaphragm 40. On one side of the first pole piece 10 , the third second pole piece 20 is arranged on the side of the...

no. 2 example

[0061] An embodiment of the present invention provides a composite laminated cell, including a first diaphragm 30 , a second diaphragm 40 , a first pole piece 10 and a second pole piece 20 . combine figure 1 , before stacking, the first pole piece 10 is continuously arranged between the first diaphragm 30 and the second diaphragm 40, and a plurality of second pole pieces 20 are alternately arranged on the first diaphragm 30 and the second diaphragm 40 away from the first pole 10 side of sheet. That is, the first pole pieces 10 are continuously arranged between the first diaphragm 30 and the second diaphragm 40 , that is, inside the first diaphragm 30 and the second diaphragm 40 ; the second pole pieces 20 are arranged at equal intervals and alternately on the first diaphragm 30 and the outside of the second diaphragm 40 . Wherein, the width of the second pole piece 20 is W1, the accuracy of the width of the second pole piece 20 is the first precision ± A1, and the accuracy o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com