Optical fiber ribbon dry-type bushing production method

A dry-type sleeve and production method technology, applied in the direction of fiber mechanical structure, etc., can solve the problems affecting the quality of splicing, affecting the normal transmission of optical cables, environmental pollution, etc., to overcome the instability of water blocking performance, ensure normal transmission performance, and excellent The effect of transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The idea, specific process flow and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, characteristics and effects of the present invention.

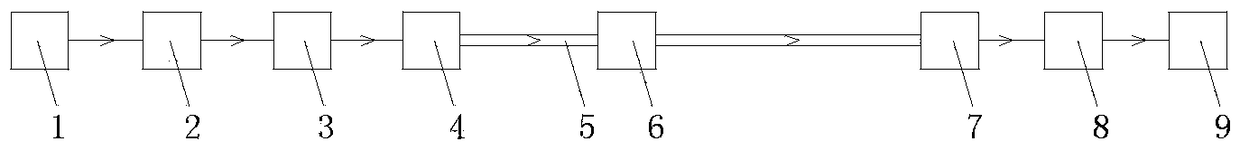

[0016] refer to figure 1 As shown, the present invention relates to a dry-type casing production method for an optical fiber ribbon, which has the following characteristics: after the optical fiber ribbon is released from the wire-releasing device 1, it passes through the ion generator 2, the water-blocking powder adding device 3, the extruder head 4, The cooling water tank 5, the excess length traction device 6, the blower 7, and the take-up traction device 8 arrive at the take-up device 9 to make an optical fiber ribbon dry sleeve.

[0017] Multiple optical fiber ribbons can be installed on the pay-off device 1 to provide a constant unwinding tension when the optical fiber ribbons are unwound, and can rotate in one dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com