Detachable dustproof and ventilating net for machine cabinet

A detachable and ventilating mesh technology, applied in cooling/ventilation/heating renovation, chassis/cabinet/drawer parts, electrical equipment shell/cabinet/drawer, etc. Enter the cabinet, the cooling effect of the cabinet is not good, and the cabinet door cannot be disassembled, etc., to achieve the effect of convenient cleaning and replacement, rapid heat dissipation, and increased air contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

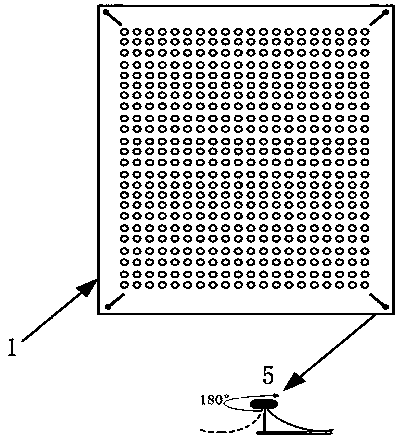

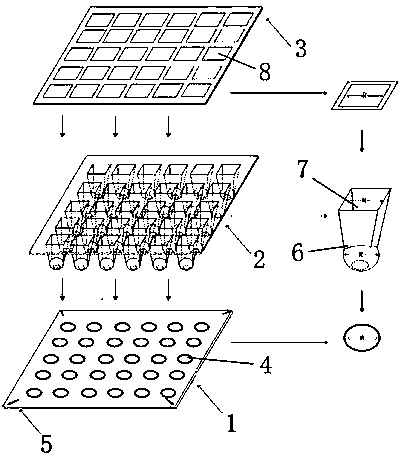

[0016] Such as figure 1 , 2 As shown, the detachable cabinet dust-proof ventilation net includes a filter screen frame 1, a silica gel heat-conducting layer 2 and a carbon fiber adsorption layer 3, wherein the filter screen frame 1 is provided with a number of through holes 4 periodically distributed; the carbon fiber adsorption layer 3, The silica gel heat conduction layer 2 is sequentially laid on the filter screen frame 1 from top to bottom; the filter screen frame 1 clamps and fixes the carbon fiber adsorption layer 3 and the silica gel heat conduction layer 2 through the buckle device 5 .

[0017] The filter frame 1, which is fixed on the cabinet body, can be used as an integral part of the front door and side door of the cabinet to ensure the cabinet’s anti-pressure effect; the silicone heat-conducting layer 2 covers the surface of the above-mentioned filter frame 1 and plays a role of heat conduction; The carbon fiber adsorption layer 3 covers the surface of the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com