Blister packaging machine

A blister packaging machine and blister packaging technology, applied in packaging, biological packaging, multiple packages, etc., can solve the problems of easy deformation of the bag, difficult to install the adhesive sheet, etc., to prevent damage and good use convenience , The effect of improving the convenience of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

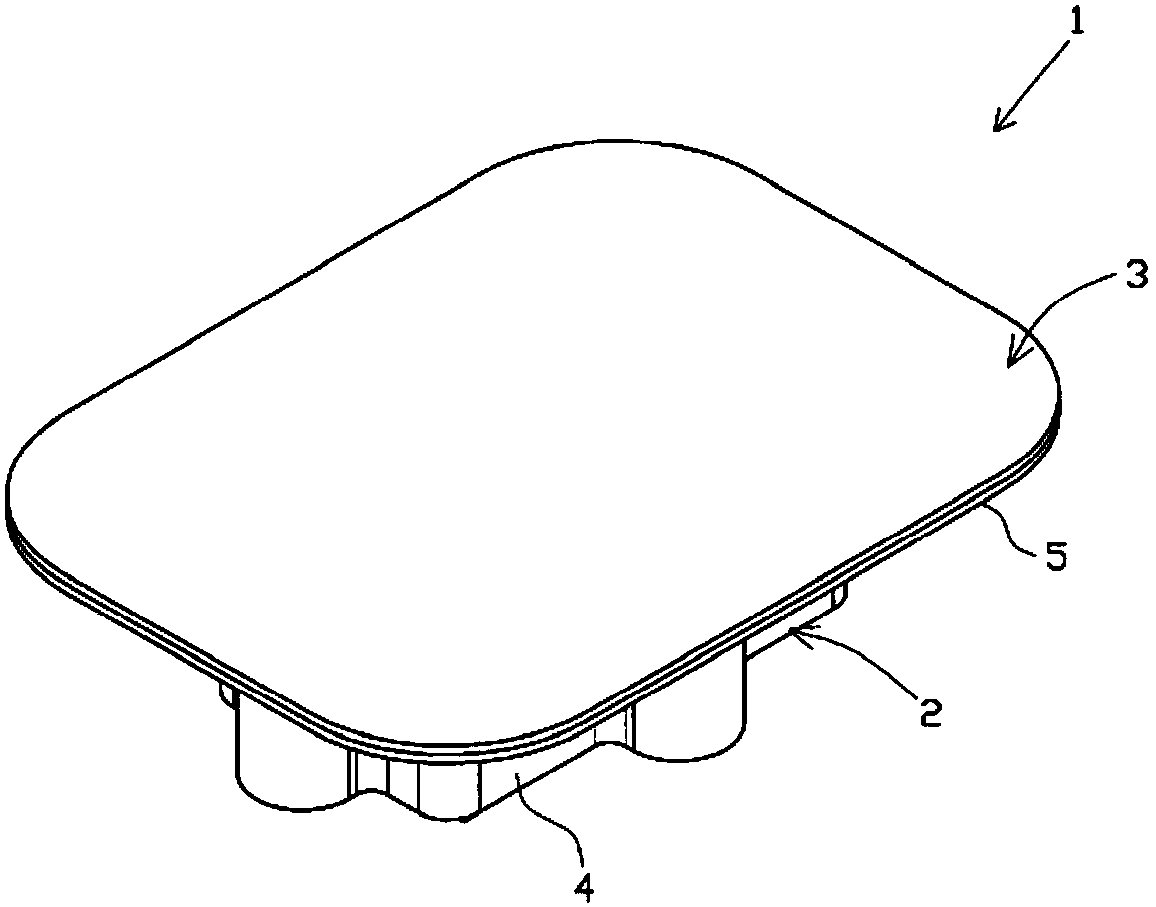

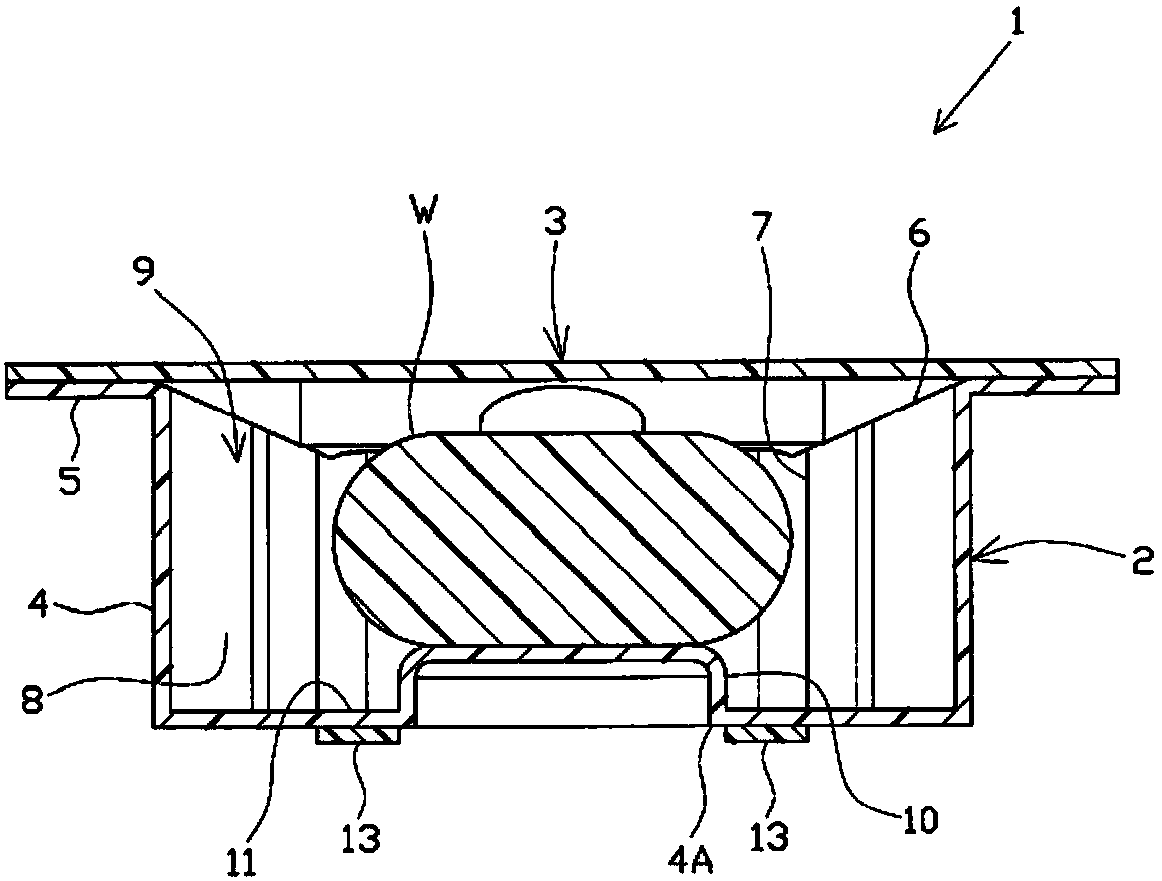

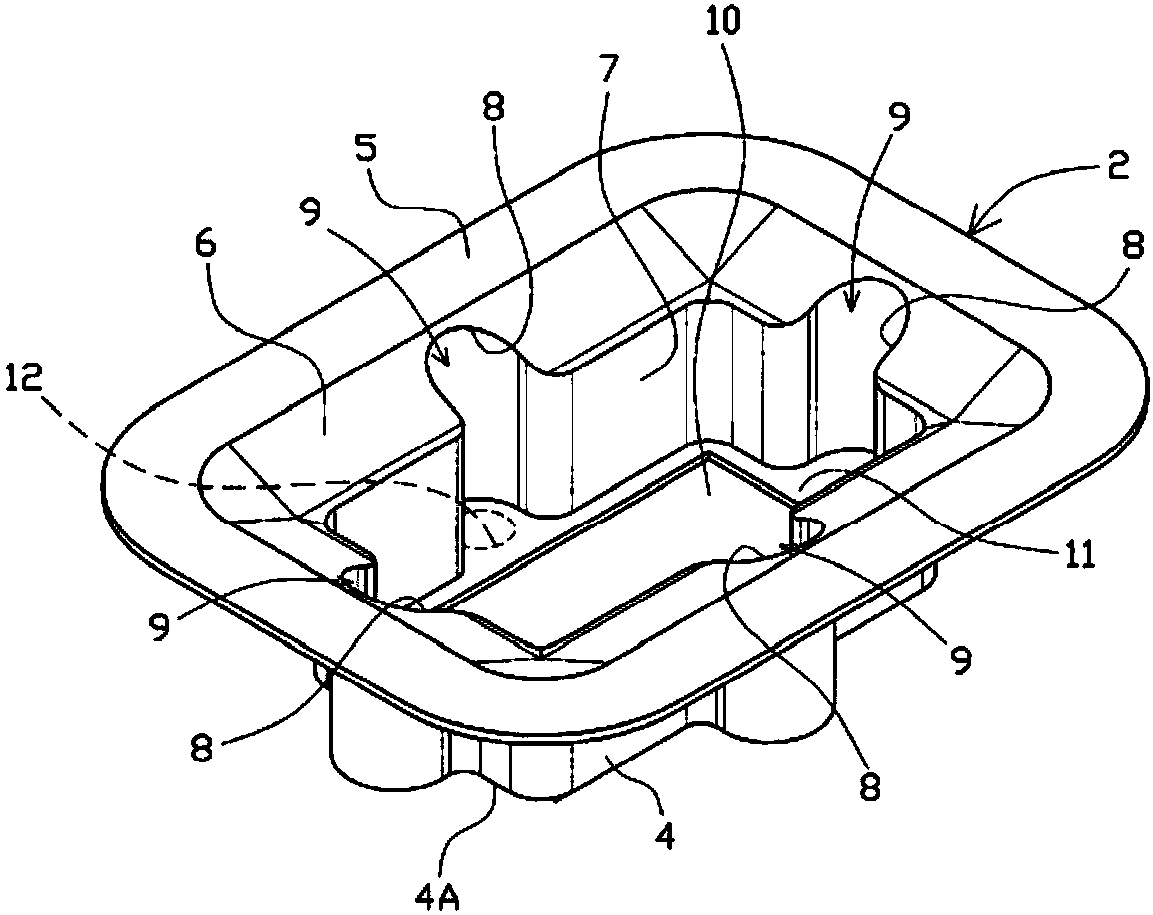

[0056] Hereinafter, an embodiment will be described with reference to the drawings. Like figure 1 with figure 2 As shown, the blister package 1 includes a container film 2 and a blister film 3 mounted on the container film 2. in figure 1 Among others, the wall thickness of the container film 2 and the blister film 3 is larger than the actual size.

[0057] The container film 2 is made of a thermoplastic resin material such as PP (polypropylene), PVC (polyvinyl chloride), PE (polyethylene), or the like. The cover film 3 is made of, for example, a thermoplastic resin material having compatibility with the container film 2 described above.

[0058] In addition, the container film 2 includes: a bag portion 4 for receiving a predetermined workpiece W (in this embodiment, solid soap); a flange-shaped flange portion 5 from which the flange portion 5 The opening side part of the bag part 4 is extended and formed to the outside. At least the top surface of the flange portion 5 is flat, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap