Small-size coal-fired boiler flue gas dedusting device

A technology for coal-fired boilers and dust removal devices, which is used in combination devices, gas treatment, membrane technology, etc., can solve the problems of no flue gas sampling structure, inconvenient operation, complex structure, etc. The effect of a large air intake rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

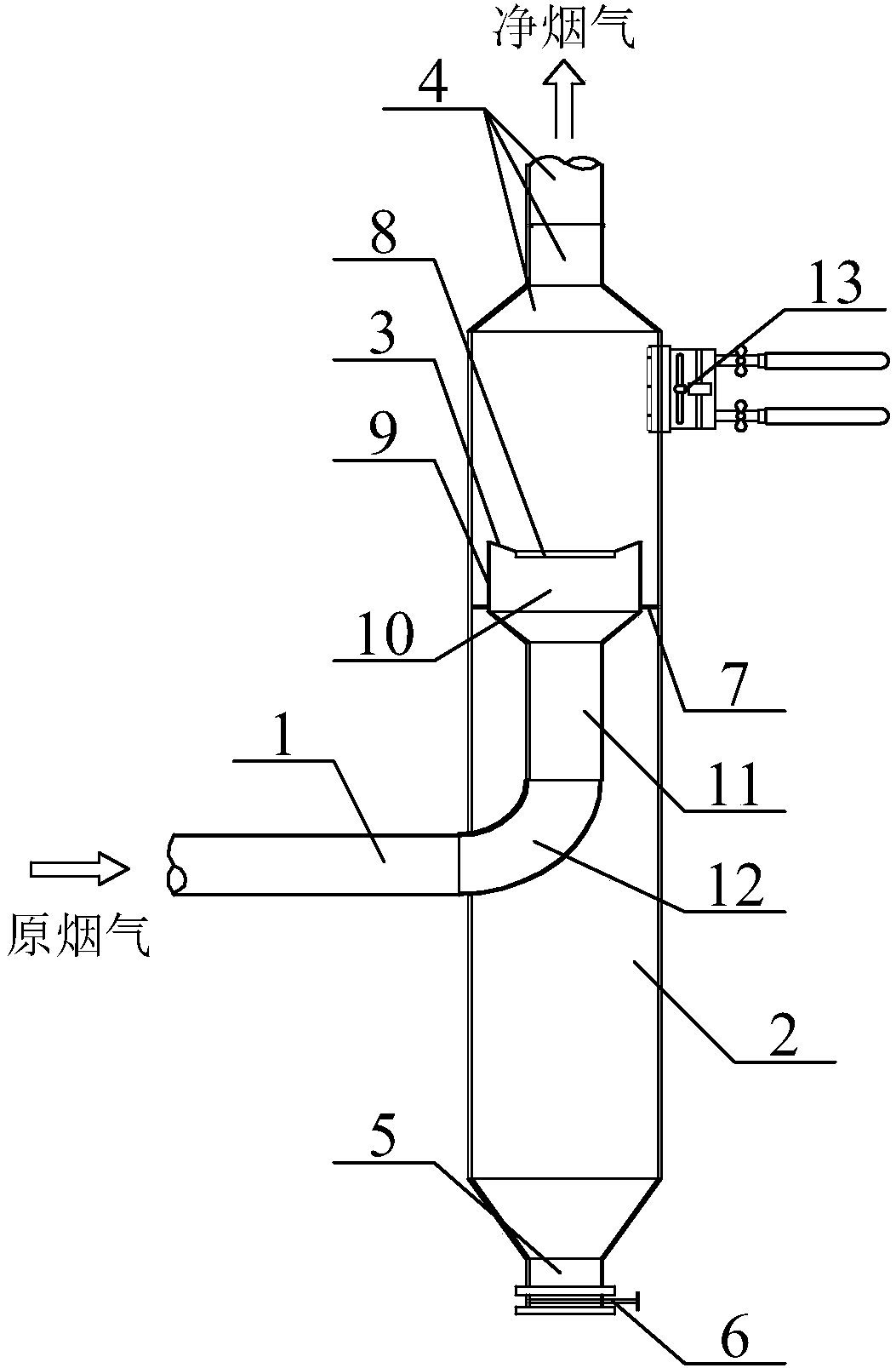

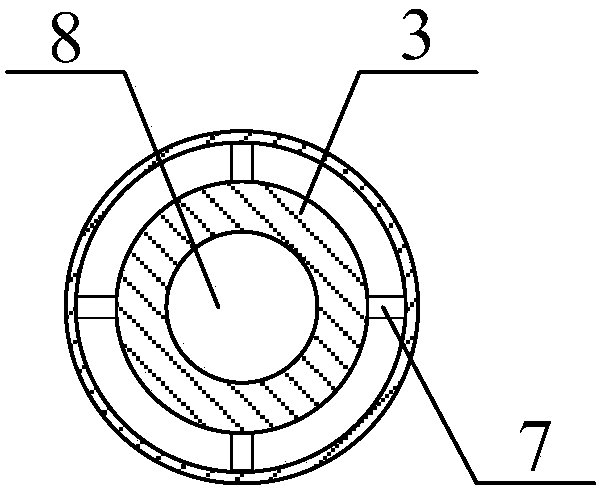

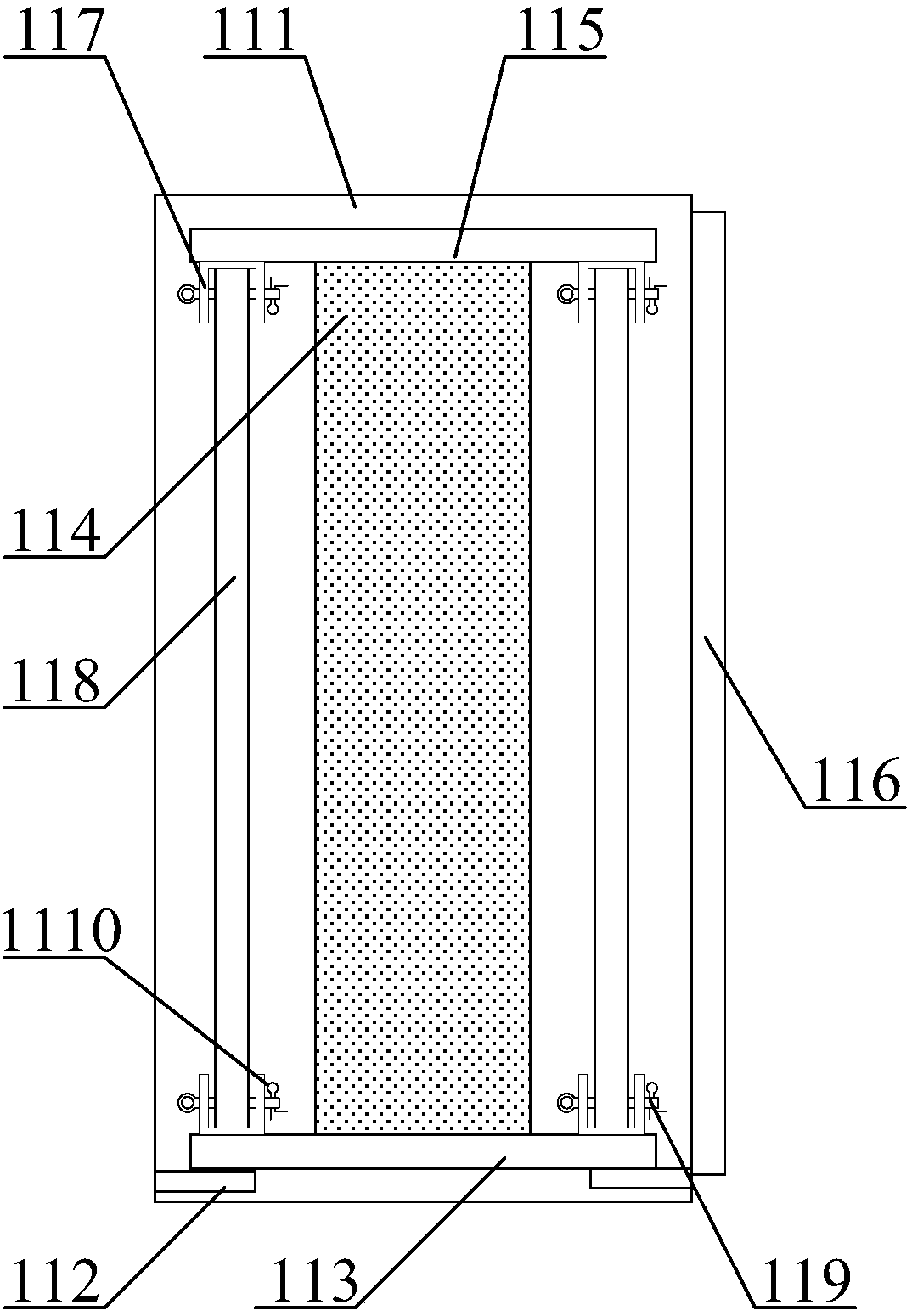

[0051] as attached figure 1 To attach Figure 5 shown

[0052] The present invention provides a small-scale coal-fired boiler flue gas dedusting device, which includes a raw flue gas pipe 1, a separation cylinder 2, a swirl plate blade 3, a clean flue gas pipe 4, a dust outlet pipe 5, a plug valve 6, and a swirl plate Support plate 7, swirl blind plate 8, swirl plate cover tube 9, swirl plate main body 10, flue gas deodorization cleaning pipe structure 11, flue gas purification adsorption ball structure 12 and clean flue gas sampling pipe structure 13, the The original flue gas pipe 1 is threadedly connected to the entrance of the left end of the flue gas purification adsorption ball structure 12; the flue gas purification adsorption ball structure 12 is placed in the inner lower middle position of the separation cylinder 2; the flue gas purification adsorption ball structure The structure 12 is screwed to the lower end of the flue gas deodorization cleaning pipe structure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com