A kind of nickel-iron slag oxalate chemically bonded cementitious material

A technology of oxalate chemistry and nickel-iron slag, applied in the field of building materials, can solve the problems of unfavorable construction operation, fast solidification speed and high price, and achieve the effects of improving solidification speed, reducing preparation cost and reducing construction difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) The ferronickel slag oxalate chemically bonded cementitious material is composed of 1000g of ferronickel slag and 350g of acidic component (oxalic acid); the ferronickel slag is ground through an 80-mesh sieve, and the sieve residue is less than 5%;

[0020] (2) Sample preparation: Weigh the corresponding materials in step (1), add 330g of water, mix and stir for 3 minutes, quickly pour into a 20mm×20mm×20mm six-unit mold, and vibrate on a vibrating table to form nickel Iron slag oxalate chemically bonded material sample; the setting time of the test is 30 minutes, the sample is demoulded after 3 hours of molding, and the compressive strength is tested by natural curing to a certain age; the 3d compressive strength of the sample is 30.86MPa.

Embodiment 2

[0022] (1) The nickel-iron slag oxalate chemically bonded cementitious material is composed of nickel-iron slag 1000g, acid component (oxalic acid) 350g, retarder (boric acid) 60g; The amount is less than 5%.

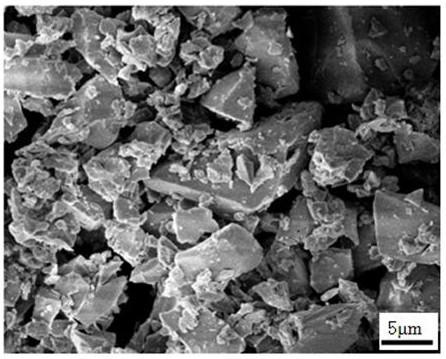

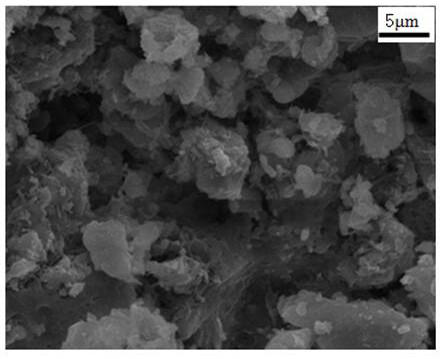

[0023] (2) Preparation of the sample: Weigh the corresponding material in step (1), add 310g of water to mix and stir for 3 minutes, quickly pour it into a 20mm×20mm×20mm six-unit mold, and vibrate on a vibrating table to form nickel Iron slag oxalate chemically bonded material sample; test its coagulation time is 55min, demold the sample after 3 hours of molding, and use natural curing method to cure to a certain age to test its compressive strength; the 3d compressive strength of the sample is 33.45MPa, The SEM of this embodiment material sees figure 2 , it can be seen from the figure that the loose irregular particles of ferronickel slag ( figure 1 ) reacts with the acidic component and retarder, and connects with the product gel as a whole to form a hardened body...

Embodiment 3

[0025] (1) The nickel-iron slag oxalate chemically bonded cementitious material is composed of nickel-iron slag 1000g, acid component (oxalic acid) 400g, retarder (boric acid) 100g; The amount is less than 5%.

[0026] (2) Preparation of sample: Weigh the corresponding material in step (1), add 300g of water to mix and stir for 3 minutes, quickly pour it into a 20mm×20mm×20mm six-unit mold, and vibrate on a vibrating table to form nickel Iron slag oxalate chemically bonded material sample; the setting time of the test is 70min, the sample is demoulded after 3 hours of molding, and the compressive strength is tested by natural curing to a certain age; the 3d compressive strength of the sample is 31.68MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com