Less-slag tapping method for electric furnace and slag baffling device

A technology of electric furnace and taphole, which is applied in the field of metallurgy, can solve difficult problems and achieve the effects of improving steel quality, improving structure and layout, and reducing production slag removal processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

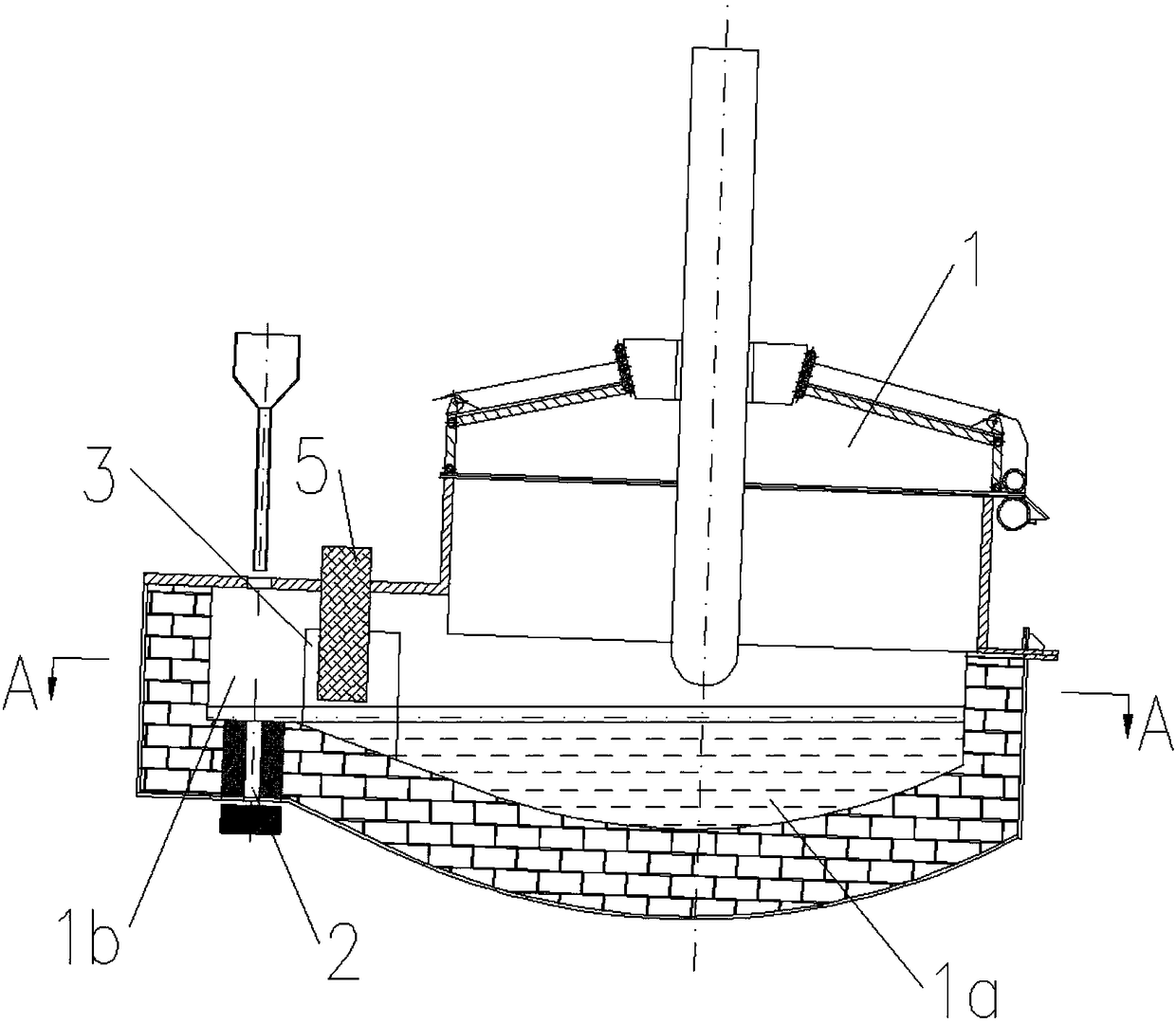

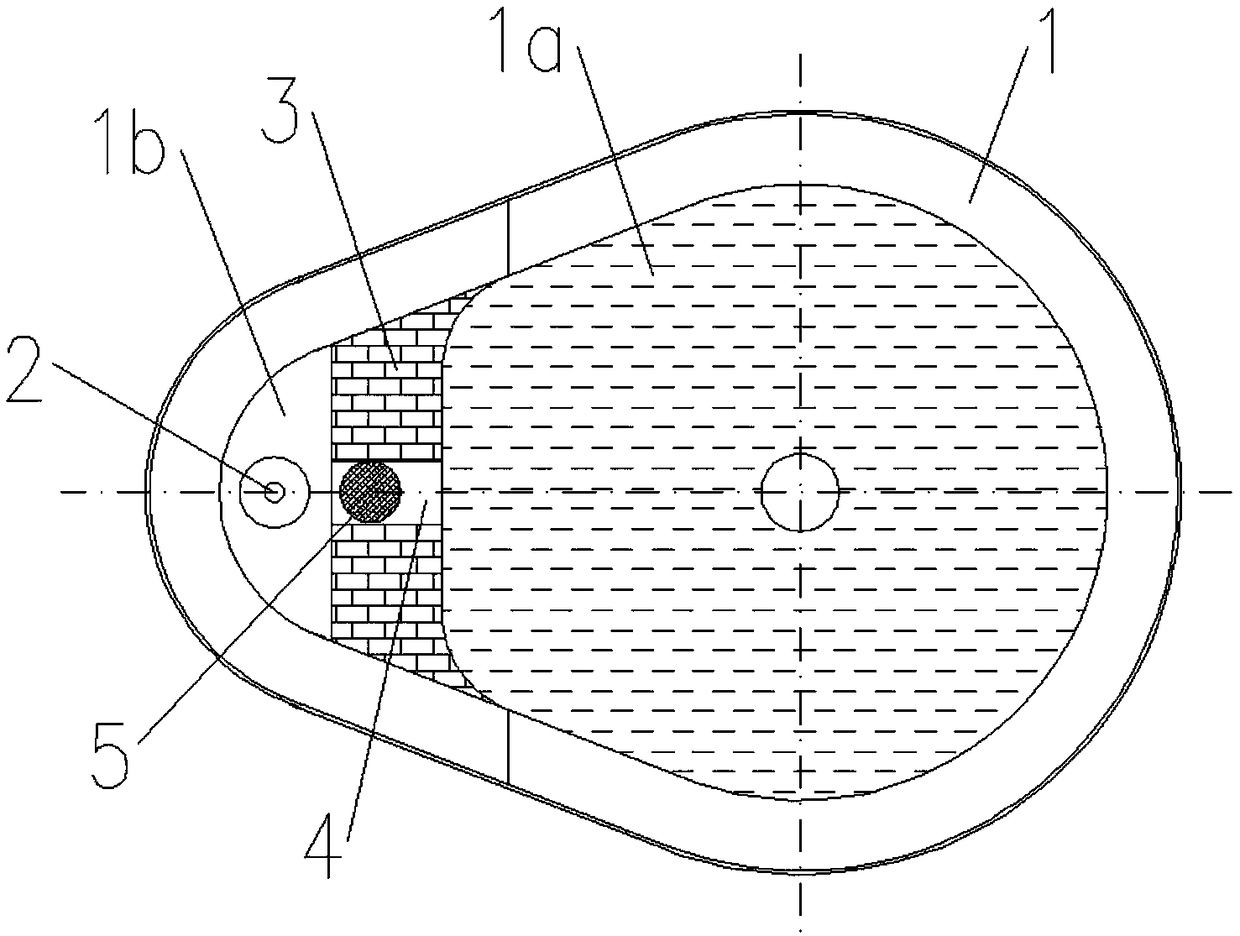

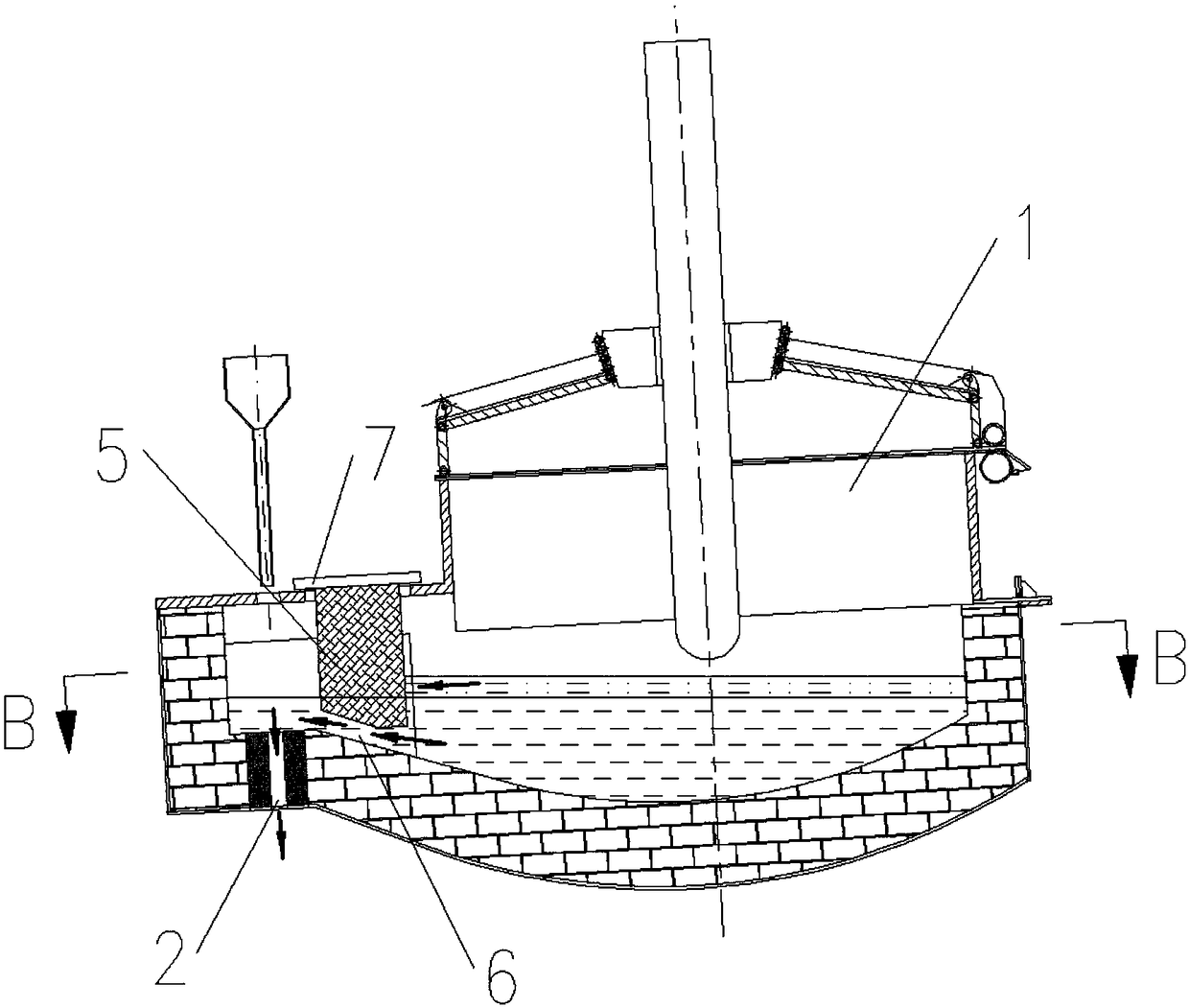

[0030] As shown in the figure, the electric furnace slag-less tapping method in the present invention includes step (1), setting up a retaining wall 3 at the front of the tapping hole 2 in the eccentric tapping electric furnace 1, the bottom and side walls of the retaining wall 3 Corresponding to the closed connection with the furnace bottom and furnace wall of the eccentric tapping electric furnace 1, so as to separate the furnace chamber of the eccentric tapping electric furnace into two regions of the electric furnace molten pool area 1a and the eccentric area 1b; step (2), on the retaining wall 3, open A long and narrow tapping launder 4 communicates with the tapping hole of the electric furnace molten pool area 1a and the eccentric area 1b. When tapping, unlike the traditional electric furnace, the molten steel must pass through the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com