Dust removal fan linkage control system and reforming method of dust removal system

A technology of linkage control system and dust removal fan, which is applied in the direction of pump control, dust removal, machine/engine, etc., can solve the problems of wasting energy and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

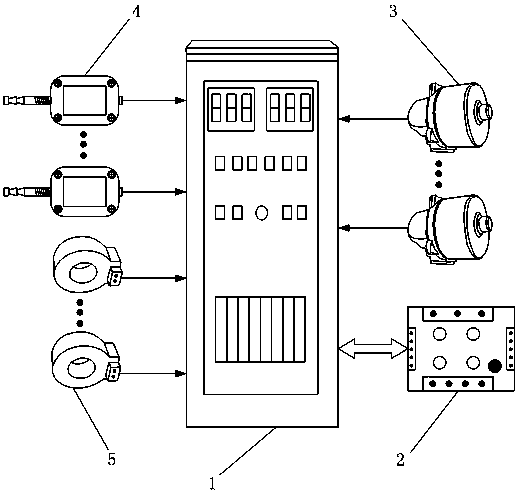

Embodiment 1

[0038] There are 3 screening production lines installed in parallel in the sintering plant. When only one of the screening production lines is turned on and the remaining two screening production lines are not working as backup, the non-working status collected by the dust removal equipment operation status signal collector 5 The operation status signal of the dust removal equipment on the two screening production lines is 0, and the operation status signal of the dust removal equipment on the working one screening production line is 1. The energy-saving controller 1 calculates the wind pressure range Q required for dust collection in the dust collection main pipeline of the dust removal system according to the dust removal equipment operation state signal collected by the dust removal equipment operation state signal collector 5, and compares the dust removal system with the non-working two The pipeline valve corresponding to the dust removal equipment on the screening product...

Embodiment 2

[0040]There are 3 screening production lines in parallel in the sintering plant. When the 3 screening production lines are all turned on, the dust removal equipment operation status signal collector 5 collects the operation status signals of the dust removal equipment on the 3 screening production lines. . The energy-saving controller 1 calculates the wind pressure range Q required for dust collection in the dust collection main pipeline of the dust removal system according to the dust removal equipment operation status signal collected by the dust removal equipment operation status signal collector 5, and connects the dust removal system with the three screening production lines The pipeline valves corresponding to the dust removal equipment on the system are all opened, so as to realize the automatic control of the pipeline valves corresponding to the dust collection point, and avoid the error and lag of manual adjustment. In addition, after the pipeline valves corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com