A test structure and test method for reliability test with independent temperature control

A technology of independent temperature control and test structure, applied in semiconductor working life test, single semiconductor device test, measurement of electricity and other directions, can solve the problems of high retest rate, high leakage requirements of probe card, long test time, etc. The effect of expanding applicable occasions, improving test efficiency and reducing test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

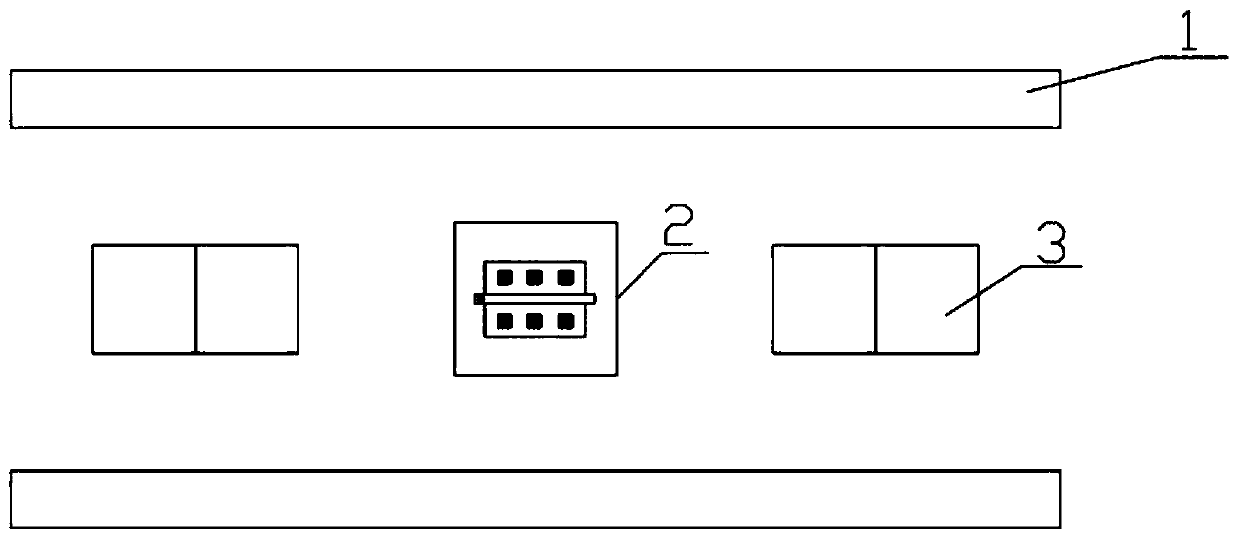

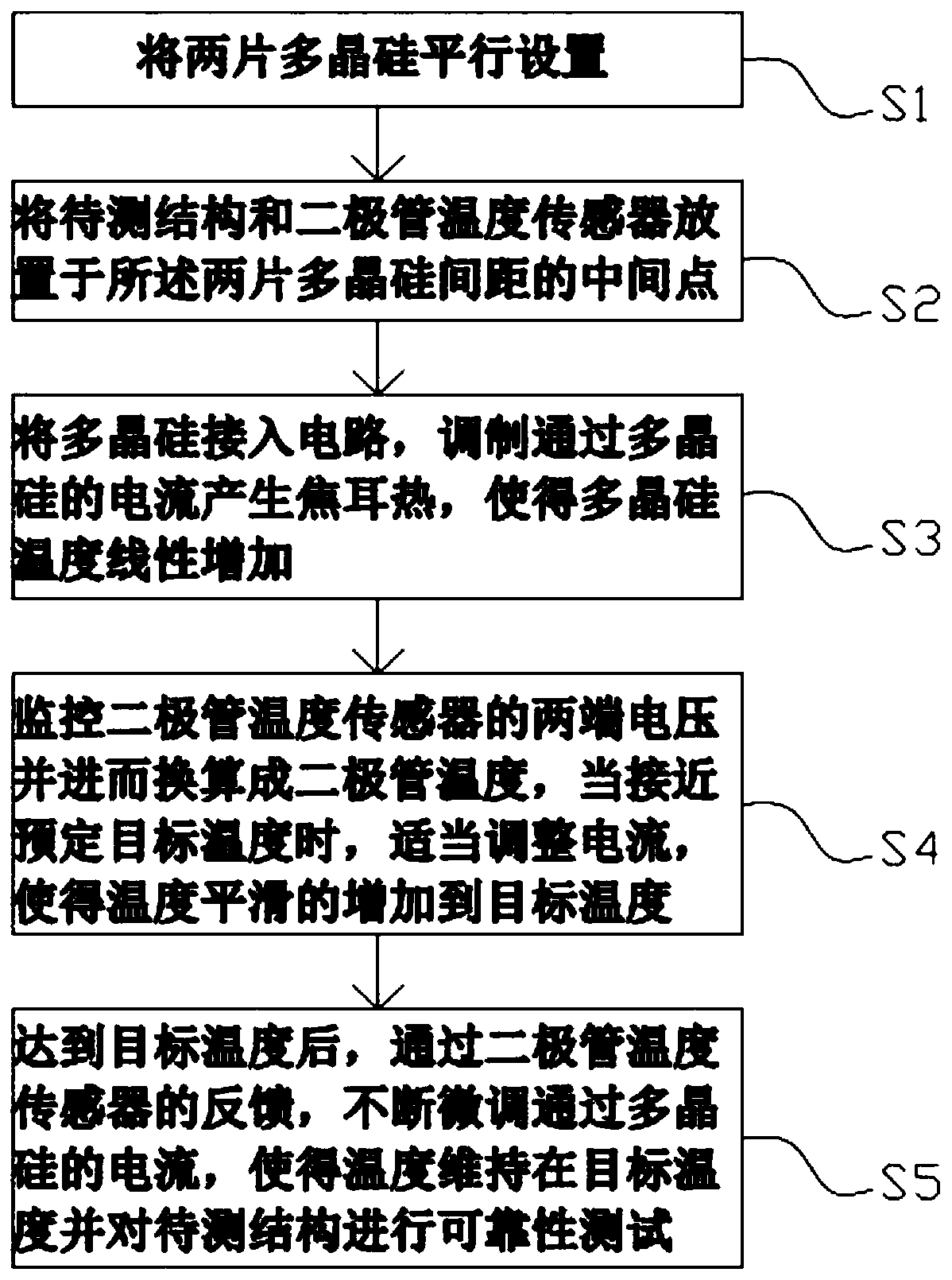

[0034] The invention provides a test structure for reliability test with independent temperature control and a test method thereof.

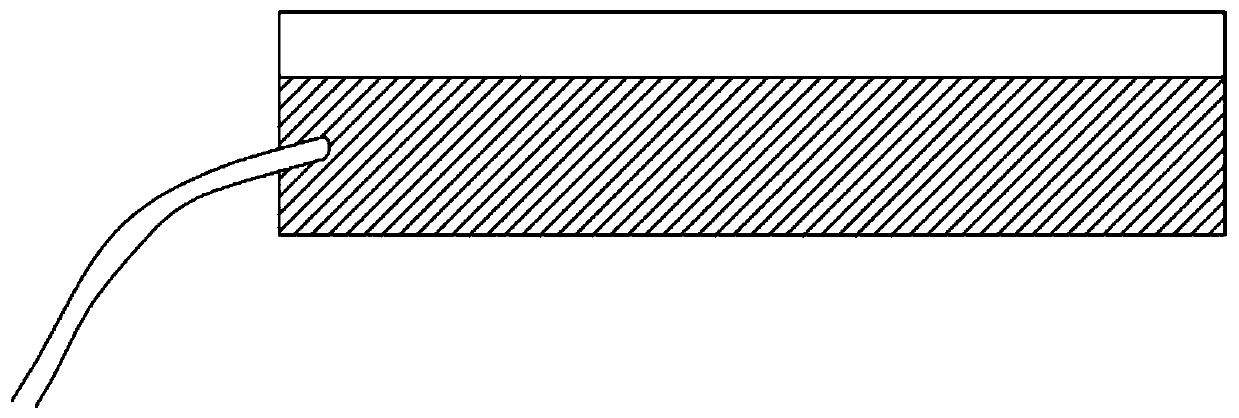

[0035] figure 1 Schematic diagram of the wafer carrier heating wafer structure used for the existing high temperature test; figure 2 A test structure for reliability testing independently temperature-controlled for a preferred embodiment of the present invention; image 3 It is a test method flow chart of a preferred embodiment of the present invention; Figure 4 It is a graph showing the polysilicon current and the voltage across the diode temperature sensor changing with time in a preferred embodiment of the present invention.

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com