High nickel and low nickel alternated shell-core-structure ternary lithium battery electrode material and preparation method

A ternary lithium battery, shell-core structure technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve problems such as shell-core segregation, and achieve the effect of uniform coating and high coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

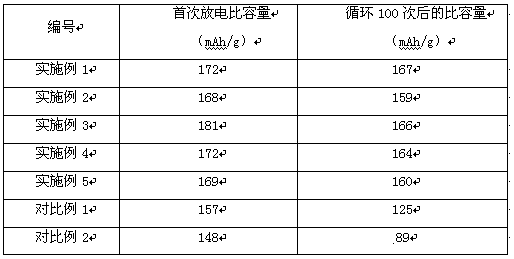

Examples

Embodiment 1

[0029] (1) Prepare high-nickel and low-nickel nickel-cobalt-lithium manganese oxide precursor solutions A and B respectively. The concentration of lithium in solution A is 0.5mol / L, the concentration of nickel is 0.4mol / L, and the concentration of cobalt is 0.05mol / L, the concentration of manganese is 0.05mol / L and B liquid, the concentration of lithium in B liquid is 0.5mol / L, the concentration of nickel is 0.25mol / L, the concentration of cobalt is 0.05mol / L, and the concentration of manganese is 0.20 mol / L;

[0030] (2) Divide the long-diameter valve inlet to the discharge port of the high-pressure homogenizer into 4 sections, each section is provided with a feeding nozzle, and the radial distance between two adjacent feeding nozzles along the long-diameter valve is 1cm ; In the long-diameter valve from the air inlet to the feed nozzle of the discharge port, the liquid A-B liquid-A liquid-B liquid is sprayed sequentially, and the air inlet of the long-diameter valve is fed ...

Embodiment 2

[0033] (1) Prepare high-nickel and low-nickel nickel-cobalt-lithium manganese oxide precursor solutions A and B respectively. The concentration of lithium in solution A is 1.0mol / L, the concentration of nickel is 0.8mol / L, and the concentration of cobalt is 0.10mol / L, the concentration of manganese is 0.10mol / L and B liquid, the concentration of lithium in B liquid is 0.5mol / L, the concentration of nickel is 0.25mol / L, the concentration of cobalt is 0.05mol / L, and the concentration of manganese is 0.20 mol / L;

[0034] (2) Divide the long-diameter valve inlet to the discharge port of the high-pressure homogenizer into 6 sections, each section is provided with a feeding nozzle, and the radial distance between two adjacent feeding nozzles along the long-diameter valve is 2cm ; (3), spray A liquid-B liquid-A liquid-B liquid-A liquid-B liquid in sequence in the feed nozzle of the long-diameter valve from the air inlet to the discharge port, and at the same time in the long-diamete...

Embodiment 3

[0037] (1) Prepare high-nickel and low-nickel nickel-cobalt-lithium manganese oxide precursor solutions A and B respectively. The concentration of lithium in solution A is 2.0mol / L, the concentration of nickel is 1.6mol / L, and the concentration of cobalt is 0.20mol / L, the concentration of manganese is 0.20mol / L and B liquid, the concentration of lithium in B liquid is 1.5mol / L, the concentration of nickel is 0.75mol / L, the concentration of cobalt is 0.15mol / L, the concentration of manganese is 0.60 mol / L;

[0038] (2) Divide the long-diameter valve inlet to the discharge port of the high-pressure homogenizer into 6 sections, each section is provided with a feeding nozzle, and the radial distance between two adjacent feeding nozzles along the long-diameter valve is 3cm ; spray A liquid-B liquid-A liquid-B liquid-A liquid-B liquid into the feeding nozzles of the long diameter valve from the air inlet to the discharge port section, and at the same time in the inlet of the long d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com