Bidirectional rotary bead extruding type splicing device and split type cigarette comprising splicing device

A two-way rotation and splicing technology, applied in the field of traditional cigarettes, can solve the problems of the small number of popping beads and the non-selectable replacement of popping beads, so as to enhance the sense of layering and fullness, avoid burns, and avoid unhygienic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

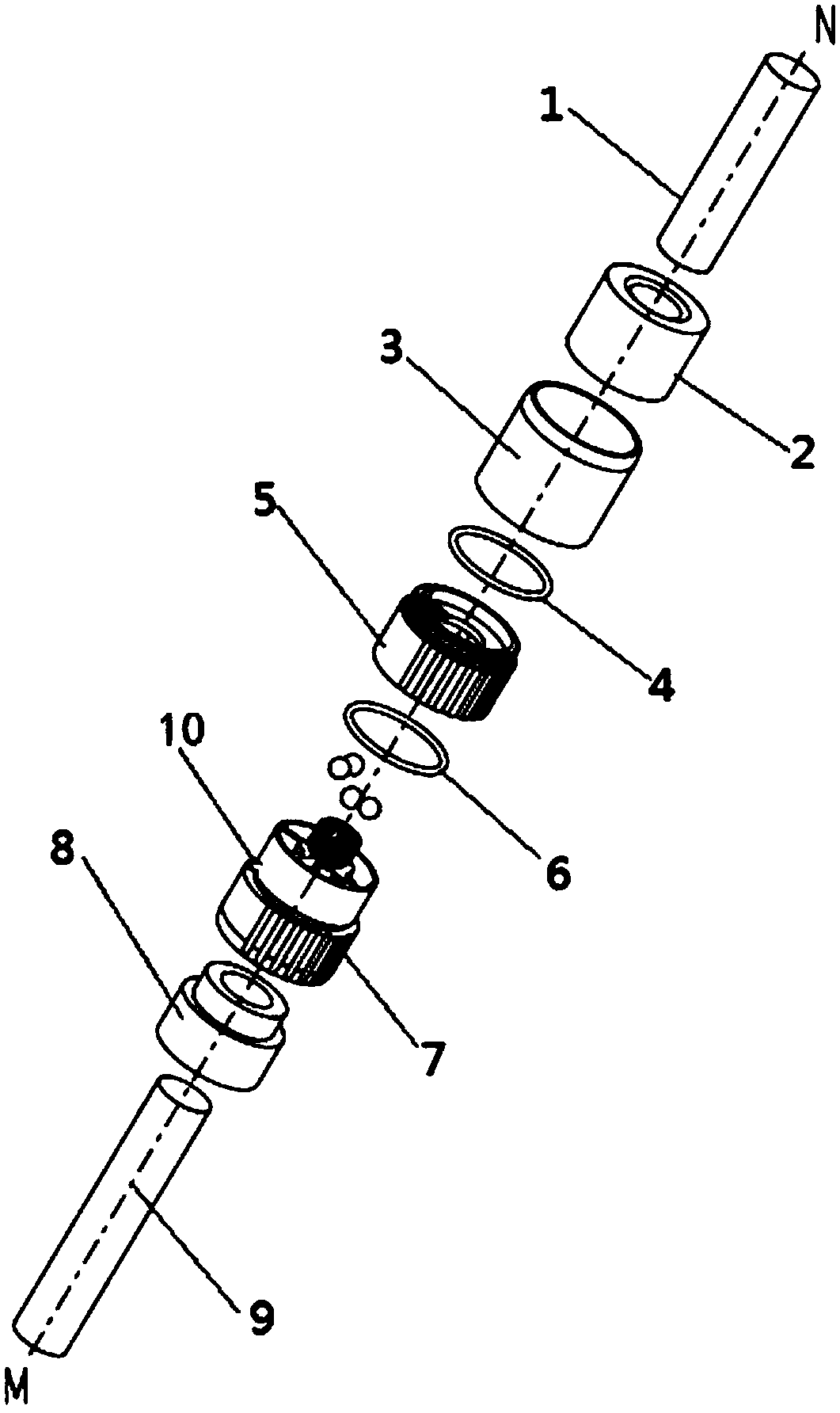

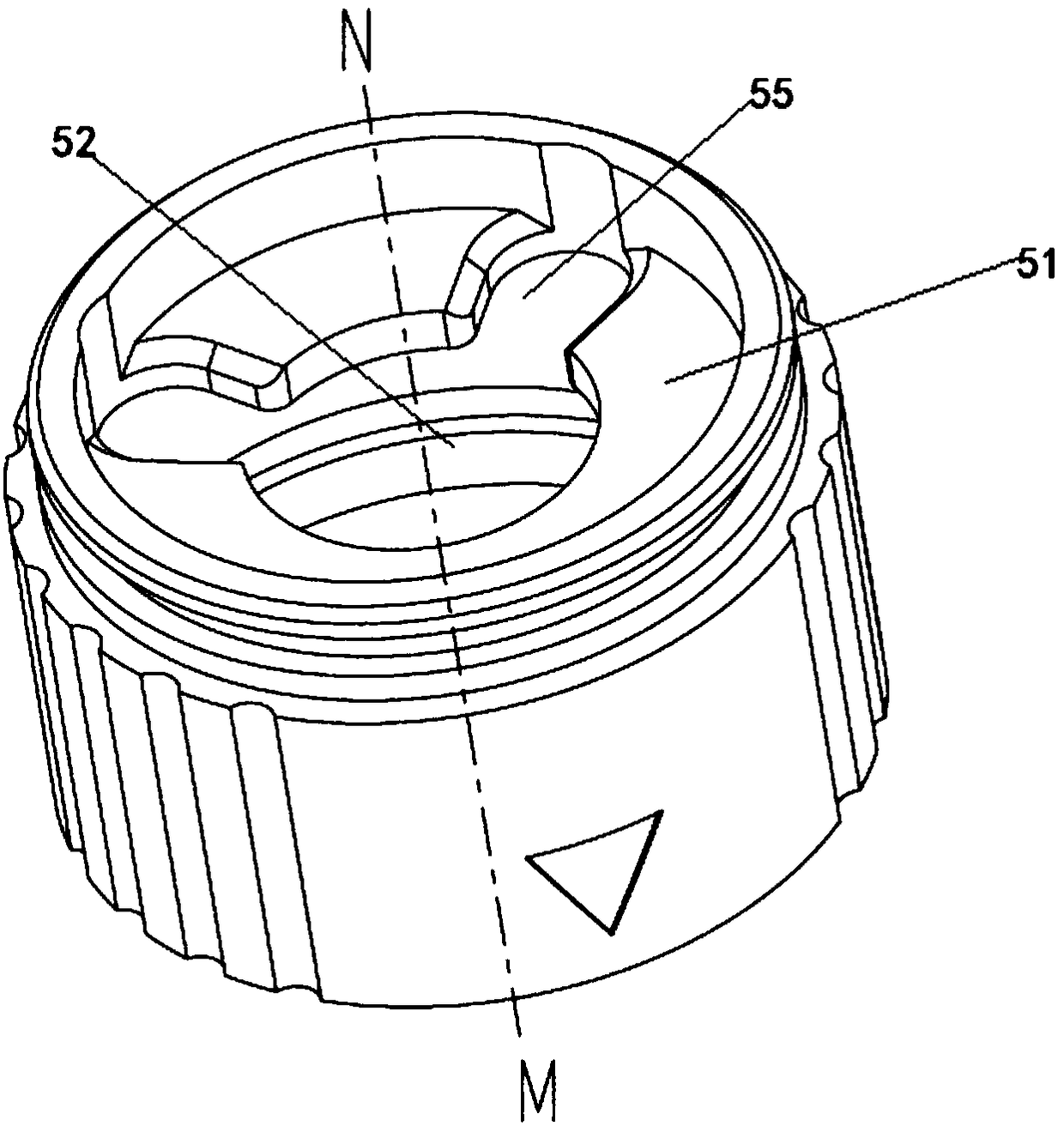

[0034] A bidirectionally rotatable bead bursting type splicer, which includes:

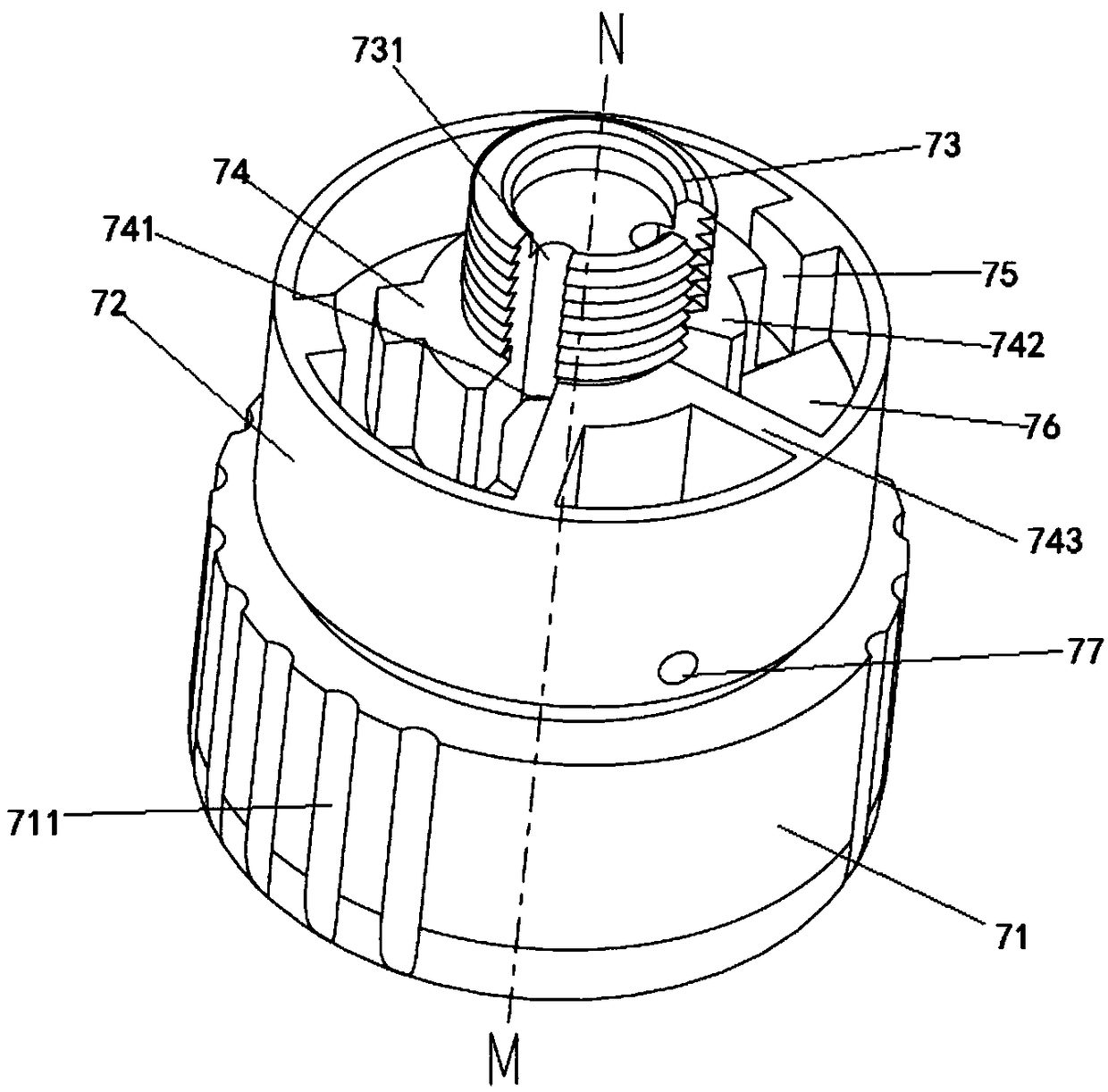

[0035] The lower screw cap 7 includes a first cylinder 71 and a second cylinder 72 with the same bottom but opposite opening directions, wherein the second cylinder 72 is provided with a third cylinder 73 coaxial with it, wherein the first cylinder The diameters of the cylinder 71, the second cylinder 72 and the third cylinder 73 decrease successively; the lower part of the third cylinder 73 is provided with a radially outwardly protruding skirt 74, the upper part of the third cylinder 73 is provided with external threads, and the skirt There are at least N skirts 743 radially extending to the inner wall of the second cylinder 72 on the side wall of the disk 74, N≥3, and the side wall of the skirt disk 74 between two adjacent skirts 743 has a skirt extending in the axial direction and passing through the The side wall and the side wall air flow passage 741 that runs through the side wall of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com