Sheep excrement treatment device

A technology for processing equipment and sheep manure, which is applied in the direction of grain processing, etc., can solve the problems of easily damaged casing connecting parts, stop production, economic loss, etc., and achieve the effects of simplifying the structure, prolonging the service life, and saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

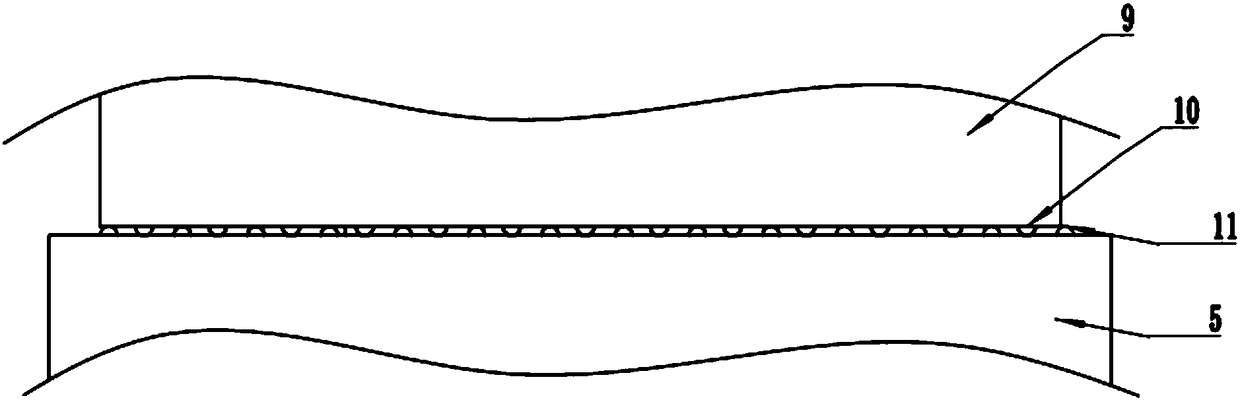

[0039] The reference signs in this embodiment include: the casing 2, the air inlet 21, the screen 7, and the air inlet pipe 15.

[0040] Such as Figure 4 As shown, the difference between this embodiment and the first embodiment is that a portion of the casing 2 opposite to the outer edge of the screen 7 is provided with a plurality of air holes that can be opened and closed by the edge of the screen 7; The holes are divided into air inlet holes 21 and air outlet holes, both of which are located on the same side of the casing 2 and are flush in the horizontal direction. The air inlet holes 21 are connected to the hot air blower through the air inlet pipe 15 for Hot air is introduced into the casing 2. The edge of the screen 7 is folded down to form a rib-like structure. The upper edge of the edge of the screen 7 is flush with the air inlet 21 and the air outlet (not shown in the figure), and the height of the upturned part is greater than the air inlet The diameter of the hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com