Manufacturing technology of shoe insole shaping mold and shoe insole shaping mold

A technology for shaping molds and manufacturing processes, which is applied to the manufacturing process of shoe midsole shaping molds and the field of shoe midsole shaping molds, which can solve the problems of difficulty in ensuring consistent thickness and tightness of midsoles, difficulty in continuous production, and difficult manufacturing processes, etc. , to achieve the effect of increasing the space used for placing objects, reducing the space used for placing objects, and not easily deformed or broken and scrapped

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

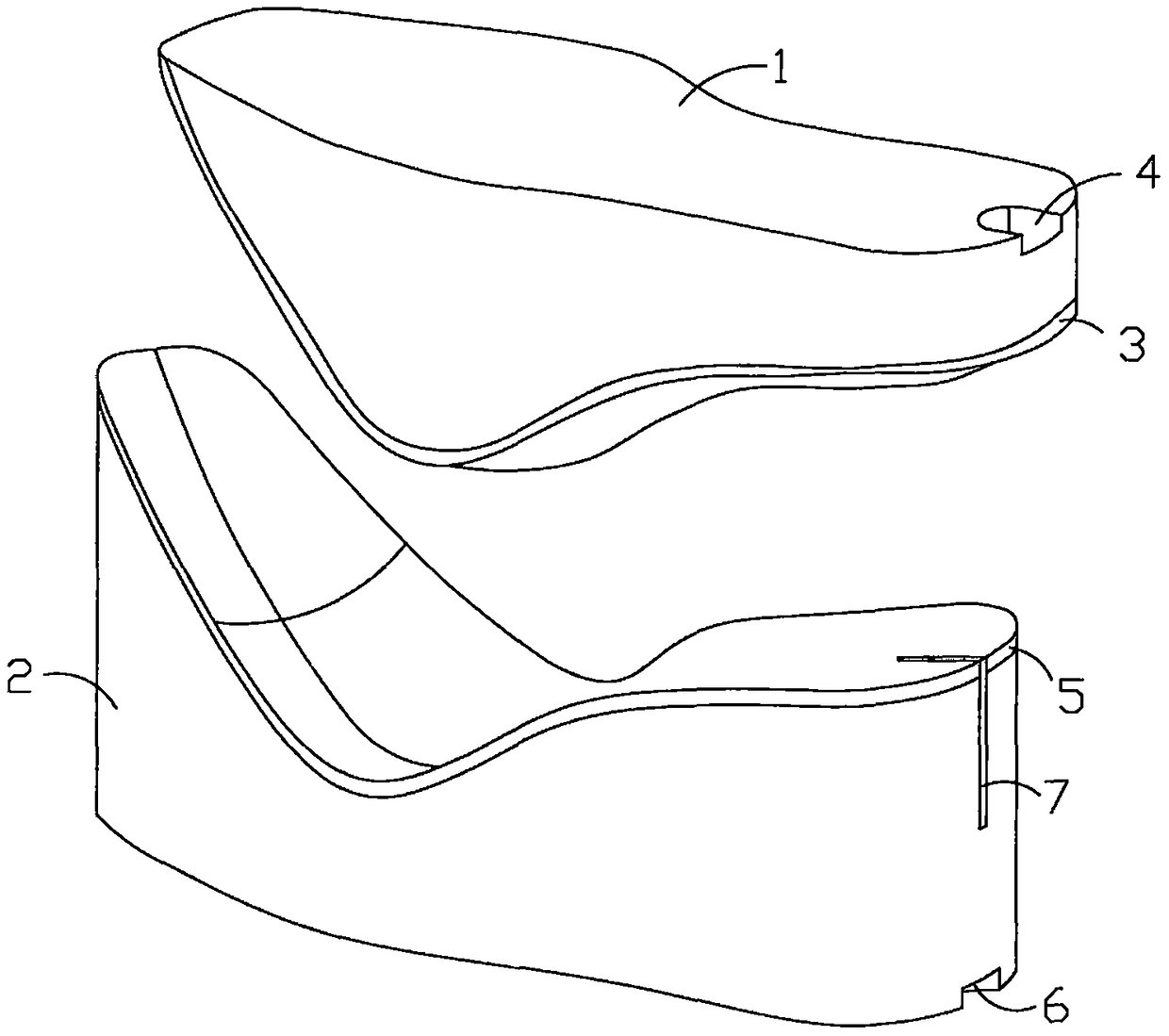

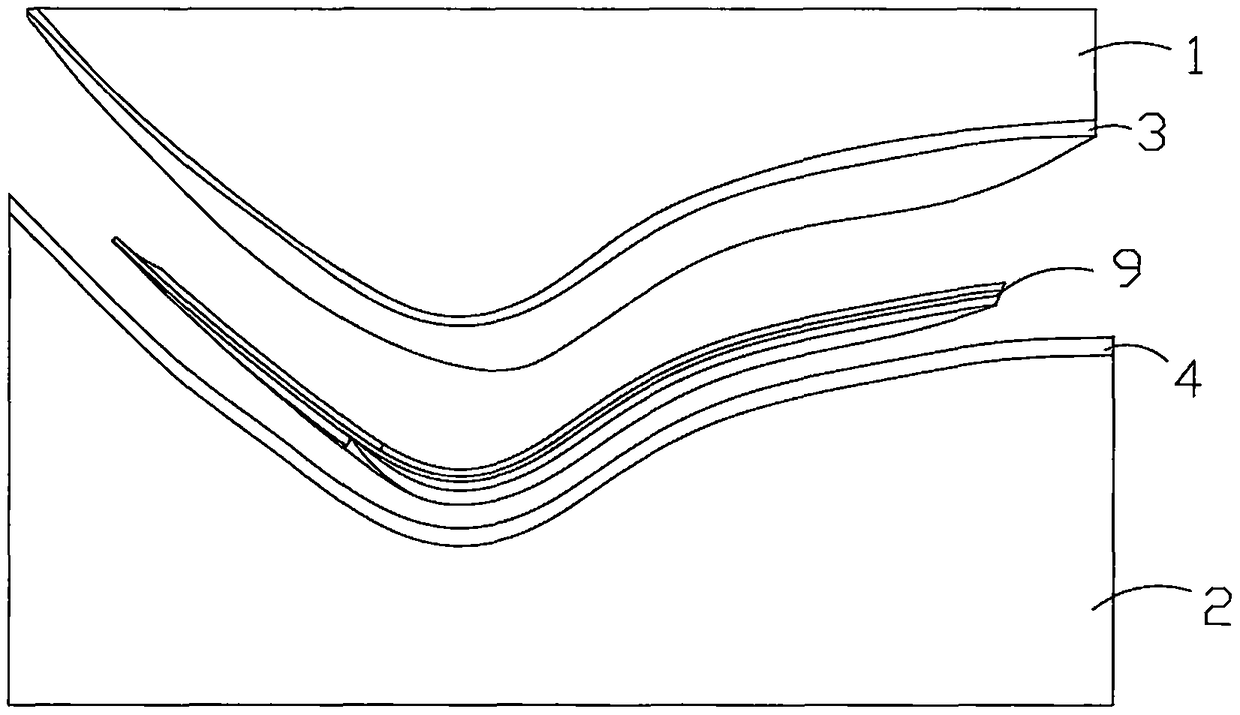

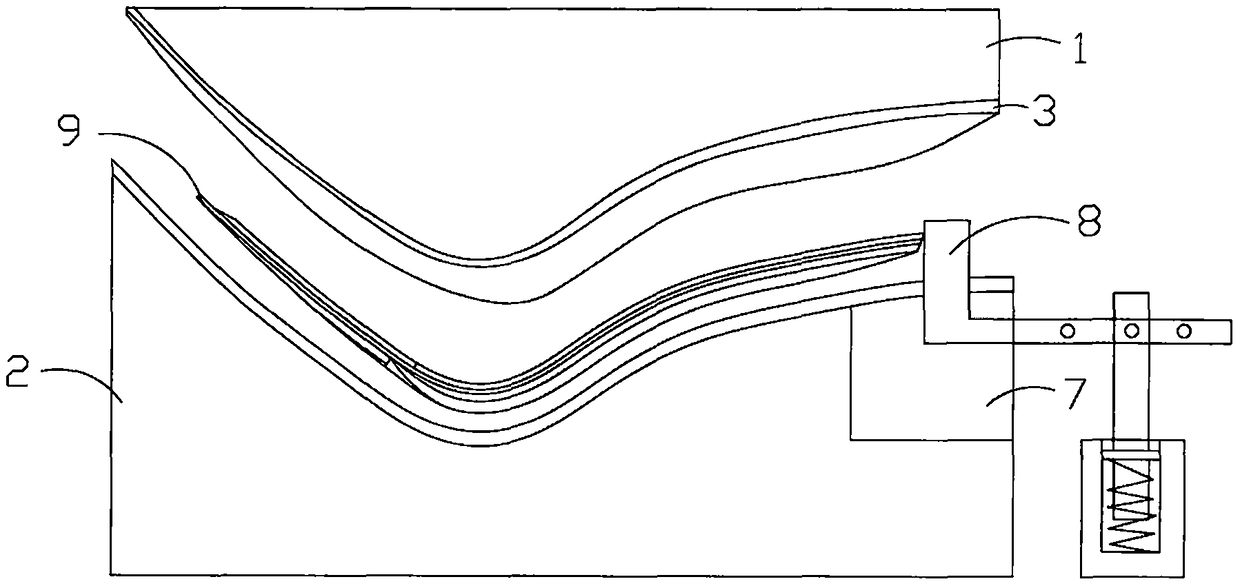

[0030] Such as Figure 1 to Figure 4 Shown, a kind of manufacturing process of shoe midsole shaping mold, comprises the following steps:

[0031] (1) According to the shoe last provided by the customer, use a 3D scanner to scan the 3D data model of the shoe last; (2), according to the 3D data model of the shoe last, use 3D software (such as Rhino software) to make the midsole of the shoe The data of the upper mold of the stereotyped mold and the lower mold; (3), according to the data of the upper mold and the lower mold of the midsole stereotyped mold, write the processing program of the upper mold of the midsole stereotyped mold and the processing program of the lower mold; (4) ), then import the machining program of the upper mold and the machining program of the lower mold into the machining center of the CNC machine tool, and carry out the processing of the upper mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com