Energy-saving-type double-motor double-station screw press

A screw press, dual motor technology, applied in the direction of presses, punching machines, manufacturing tools, etc., can solve the problems of energy loss, low motor energy efficiency, etc., and achieve the effect of improving efficiency, improving energy efficiency, and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

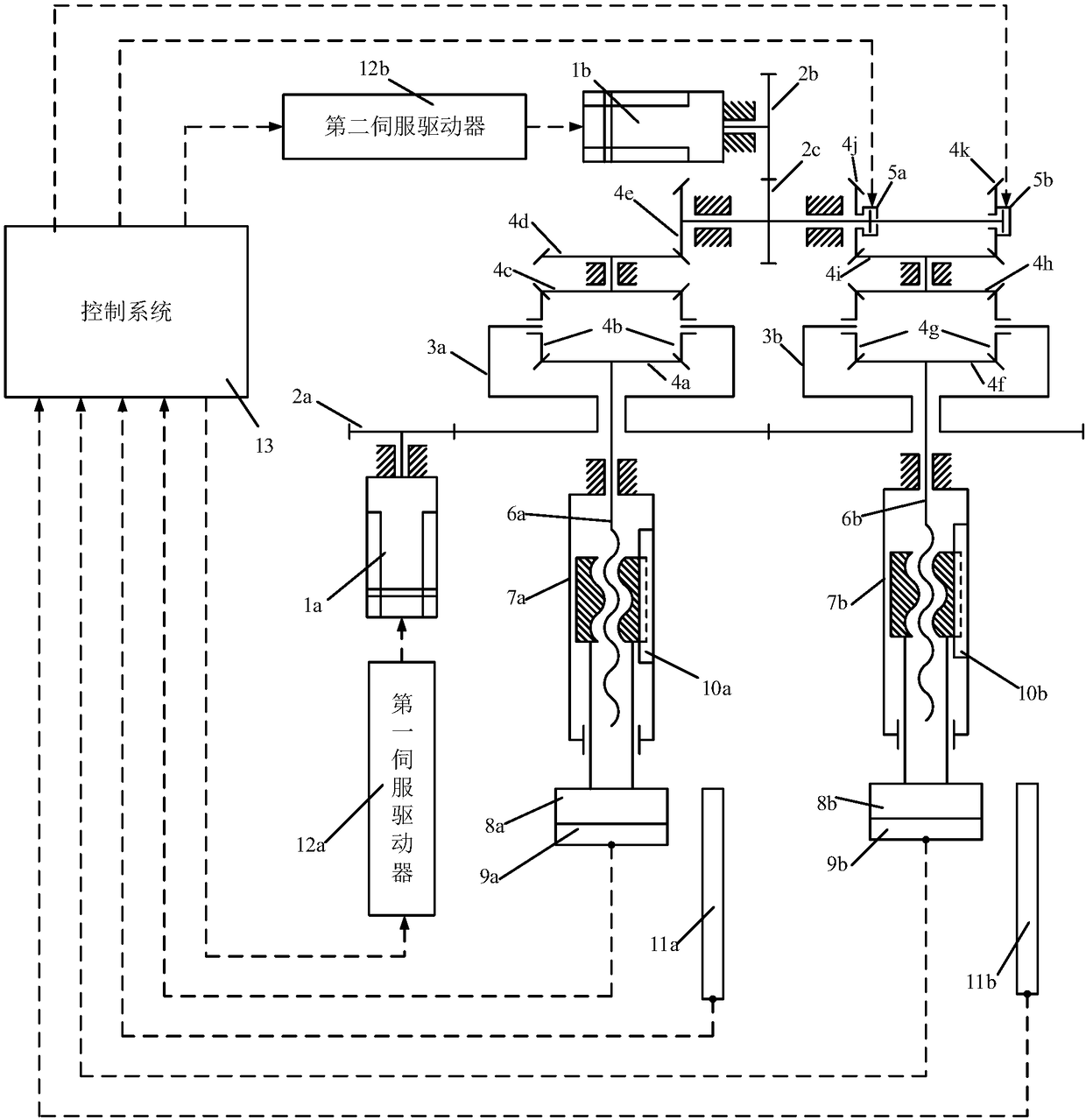

[0031] see figure 1 , the structural form of the energy-saving double-motor double-station screw press in this embodiment is:

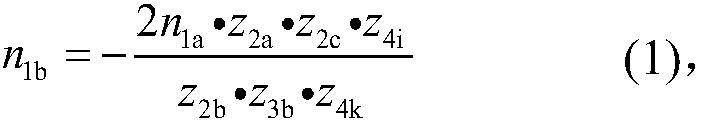

[0032] There are two sets of screw auxiliary mechanisms distributed on both sides of the press, and the two sets of screw auxiliary mechanisms are respectively composed of the first cylinder 7a, the first screw rod 6a, the first slider 8a and the first anti-rotation device 10a. The screw pair mechanism, and the second screw pair mechanism composed of the second cylinder 7b, the second screw mandrel 6b, the second slide block 8b and the second anti-rotation device 10b; the first bevel gear 4a, the second bevel gear 4b, The third bevel gear 4c and the first rotating arm 3a form the first differential gear train, and the first differential gear train takes the third bevel gear 4c and the first rotating arm 3a as input ends, and the first bevel gear 4b is the output end; the second differential gear train is formed by the sixth bevel gear 4f, the seventh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com