Folding arm-type crane counterweight system and control method thereof

A technology of cranes and counterweights, which is applied to cranes and other directions, can solve problems such as the inability to adjust the position of counterweights, and achieve the effect of reducing the number of counterweight plates, reducing the overall load, and accelerating the lifting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

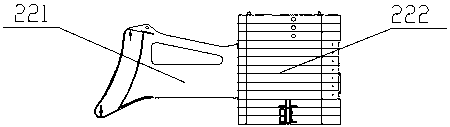

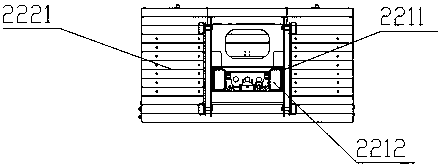

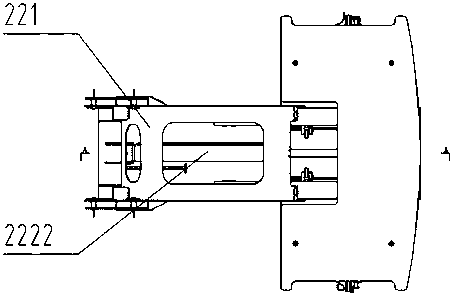

[0060] As shown in the figure, the present invention is a counterweight system of a folding-arm crane. The folding-arm crane 2 is arranged on a carrier vehicle 1, and several pairs of outriggers 11 are arranged on the carrier vehicle. The folding-arm crane includes a boom 21. A hook is provided at the head end of the boom, and a counterweight device 22 is provided at the end of the boom. The counterweight device includes a bracket 221 and a counterweight mechanism 222 movable on the bracket. The bracket 221 is fixedly located at the end of the boom of the knuckle-arm crane;

[0061] The counterweight mechanism includes a counterweight 2221 and a telescopic mechanism 2222 that drives the counterweight to move. The telescopic mechanism is arranged in the frame, and the frame 221 is provided with a rail groove 2211. A guide rail 2212 is engaged in the guide rail groove, one end of the guide rail is connected to the telescoping mechanism 2222 , and the other end of the guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com