A kind of uv photocurable resin applied to silver nanowire conductive film and preparation method thereof

A light-curing resin and silver nanowire technology, which is applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of silver nanowire conductive function damage, water resistance, bending resistance, surface hardness, and solvent resistance. and other issues, to achieve excellent transmittance, excellent fullness, and maintain the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

[0040] The raw materials of each embodiment UV photocurable resin are as shown in Table 1, and the preparation method is as follows:

[0041] Weigh each raw material according to the ratio; first add solvent to urethane acrylate, stir mechanically for 20 minutes, then add active monomer, silver stabilizer and graphene quantum dots while stirring, continue stirring for 20 minutes, then add ATO, ultrasonically disperse for 30 minutes, get the mixture;

[0042] The silver nanowire transparent conductive ink is coated on the PET substrate to form a conductive layer to obtain a silver nanowire conductive film.

[0043] Add a photoinitiator to the mixture and stir evenly to obtain a UV photocurable resin; then use a dimple coater to uniformly coat the UV photocurable resin (coating speed is 20m / min) on the silver nanowire conductive film, Then cured by UV light (using UVLED lamp, curing energy 800mJ / cm 2 ) to form a UV protective film layer.

Embodiment 8

[0045] For comparison, the same formula and method as in Example 1 were used to obtain UV photocurable resin and form a UV protective film layer, the only difference being that the polyurethane acrylic resin of Example 1 was replaced by CN2920 with CN104NS epoxy acrylate.

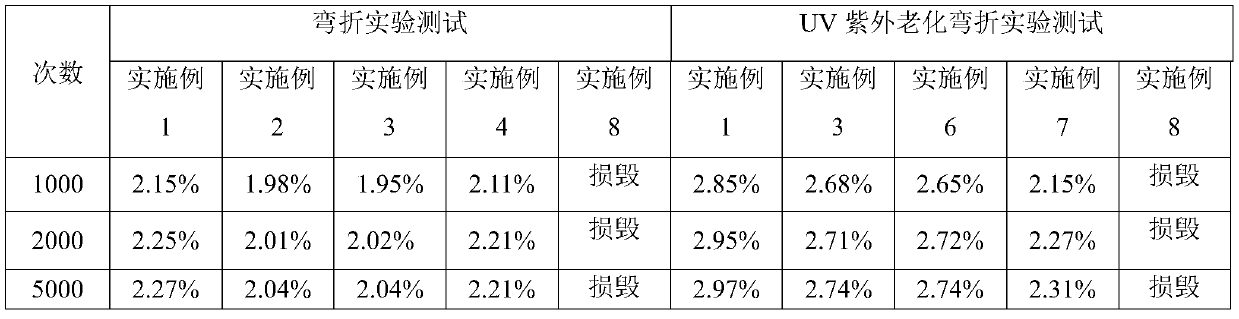

[0046] Table 1

[0047] Example CN2920 solvent active monomer silver stabilizer Graphene Quantum Dots ATO Photoinitiator 1 1.5g 95g 1.5g 0.001g 0.001g 0.001g 0.075g 2 3g 95g 1.5g 0.001g 0.001g 0.001g 0.075g 3 4.5g 95g 1.5g 0.001g 0.001g 0.001g 0.075g 4 1.5g 95g 1.5g 0g 0.001g 0.001g 0.075g 5 1.5g 95g 1.5g 0.001g 0.001g 0g 0.075g 6 4.5g 95g 1.5g 0.001g 0.005g 0.001g 0.075g 7 1.5g 95g 1.5g 0.001g 0.001g 0.005g 0.075g

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com