Variable-stiffness single-degree-of-freedom dynamic damping boring rod

A technology of dynamic vibration reduction and degree of freedom, which is applied in the direction of boring bar, spring/shock absorber, vibration suppression adjustment, etc., can solve the problems of high cost, small variation range, and no accurate corresponding relationship of extrusion degree, and achieve cost Low, easy to implement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described with reference to the drawings and embodiments.

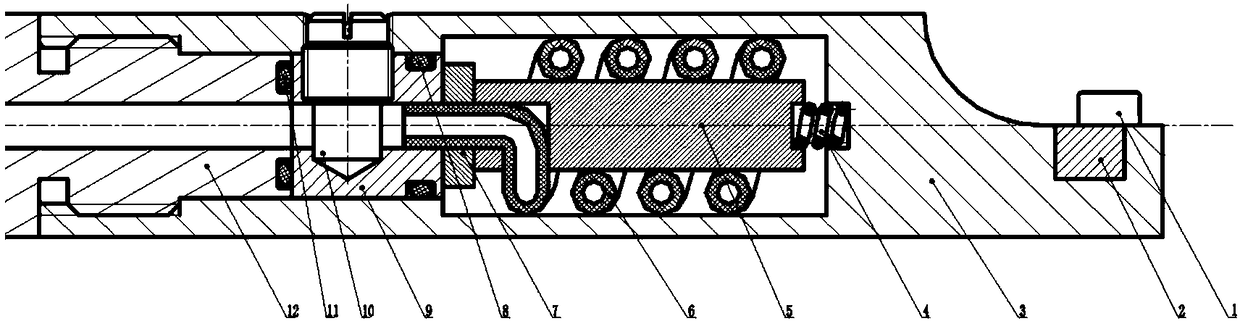

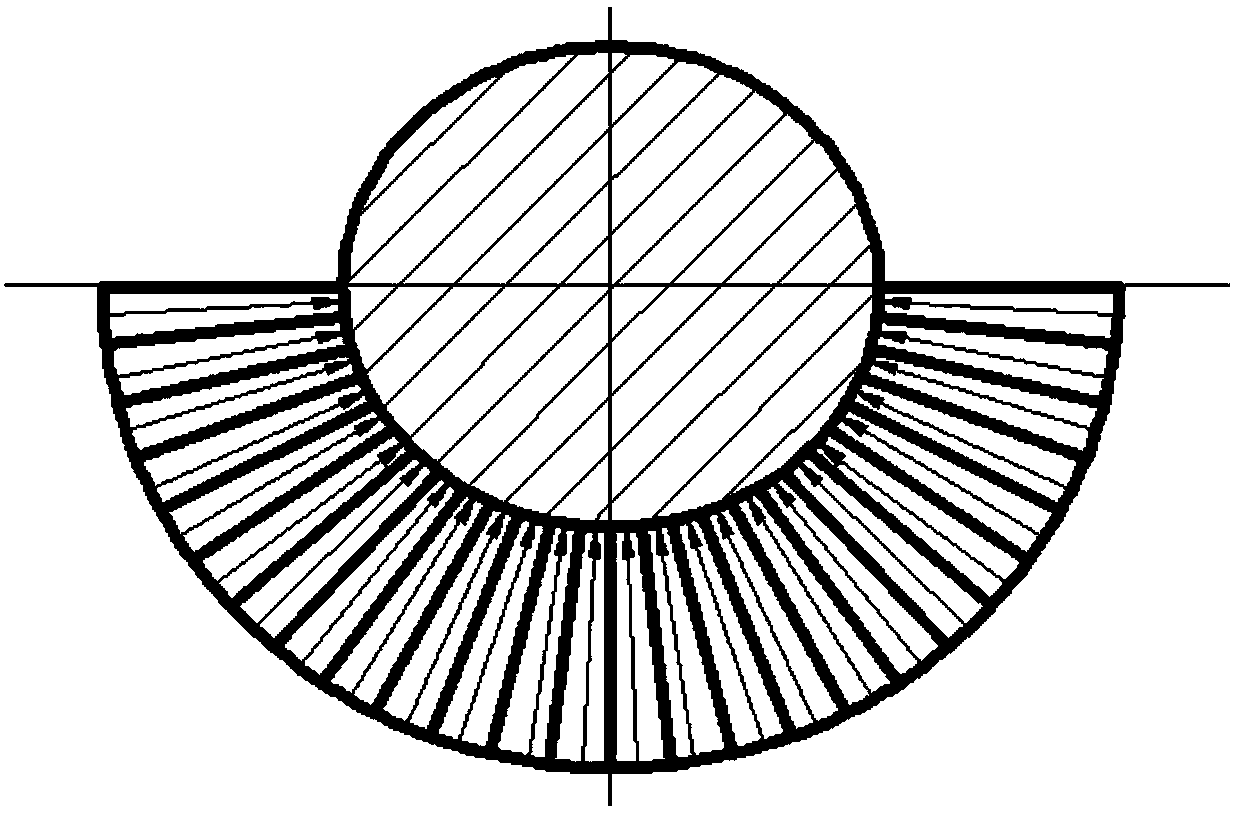

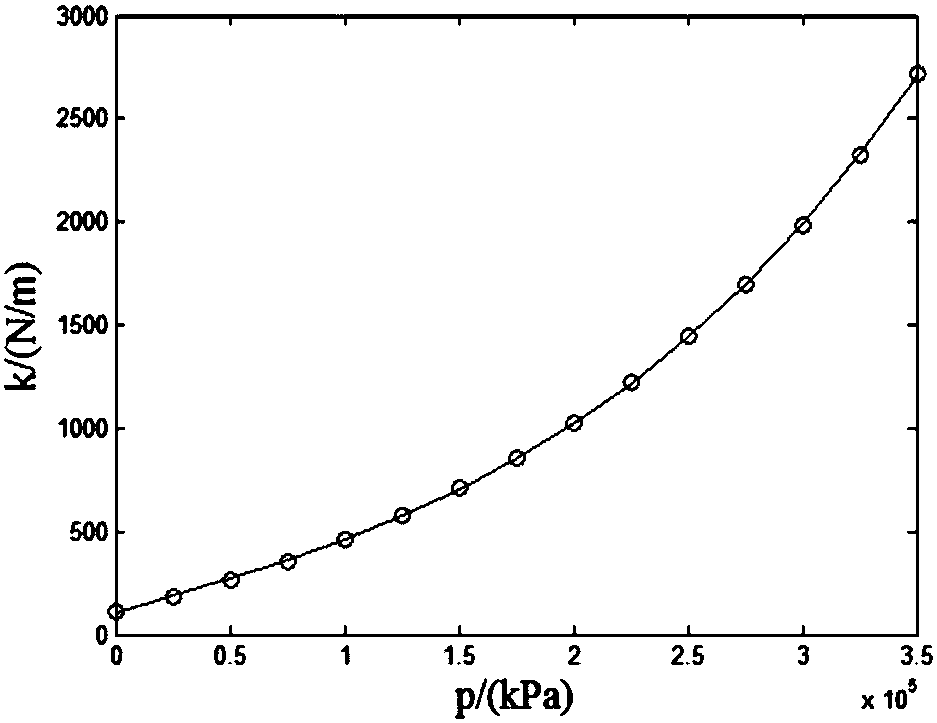

[0028] See figure 1 , A variable stiffness single degree of freedom dynamic damping boring bar of the present invention, the boring bar is assembled by 12 parts, namely the blade screw 1, the blade 2, the front half of the boring bar 3, the limit spring 4, the mass block 5. Rubber hose 6, gasket 7, first O-ring 8, plug 9, hydraulic circuit breaking screw 10, second O-ring 11, and the rear half of the boring bar 12; the front half of the boring bar 3 The threaded connection is used with the rear half 12 of the boring bar, and the threaded connection part adopts a parallel design of thread and shaft hole to compensate for the runout of the tool bar caused by the thread gap; the front end of the front half 3 of the boring bar is equipped with a blade 2 and the blade 2Fix by blade screw 1. A cavity is opened in the front half 3 of the boring bar, and a mass 5 is provided in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com