Connecting rod type overpressure control valve and control method

A control method, connecting rod technology, applied in the direction of valve details, valve device, valve operation/release device, etc., can solve the problems of short stroke, long adjustment time, slow response, etc., to achieve large action stroke, easy maintenance, The effect of effective regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

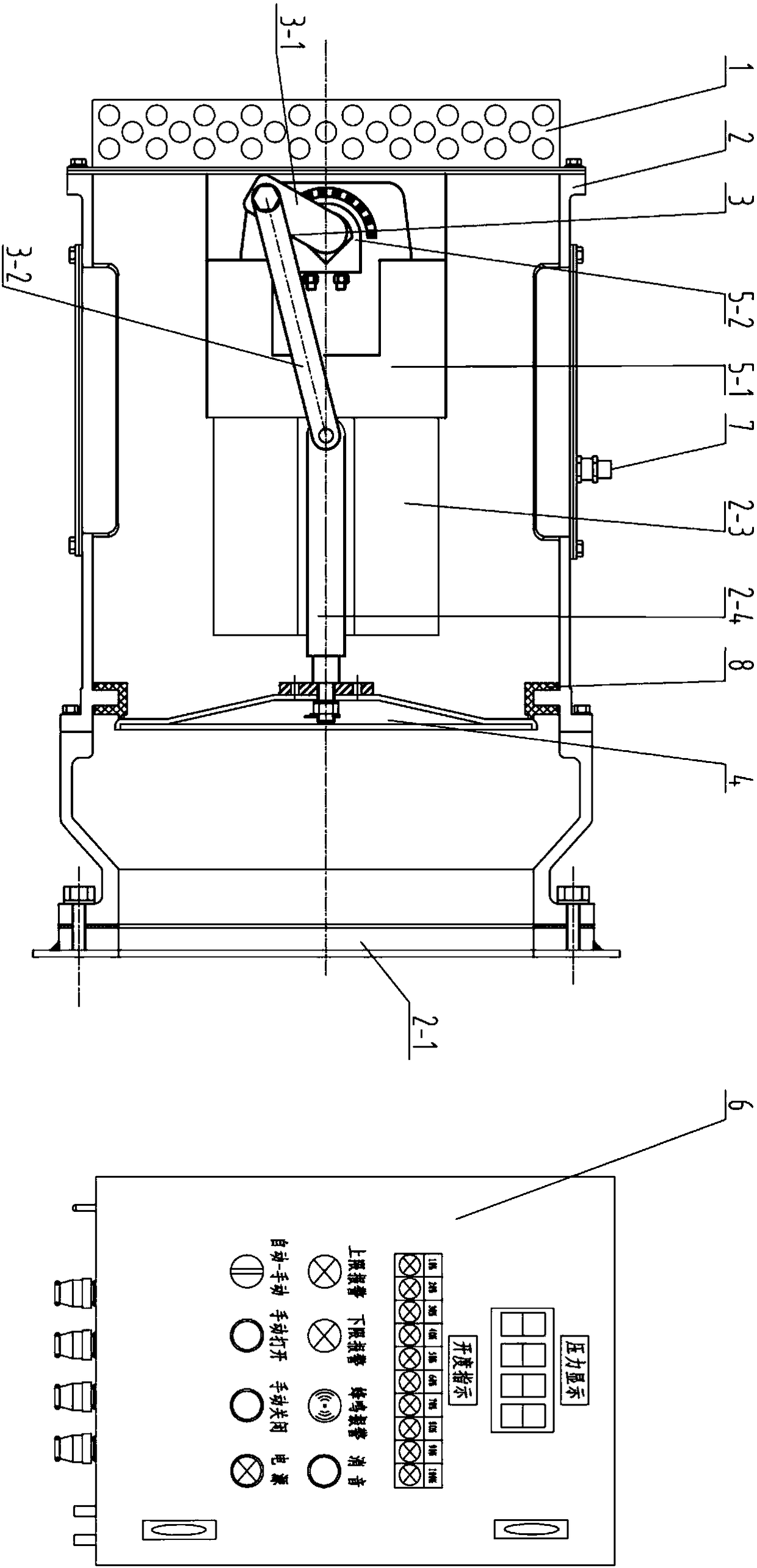

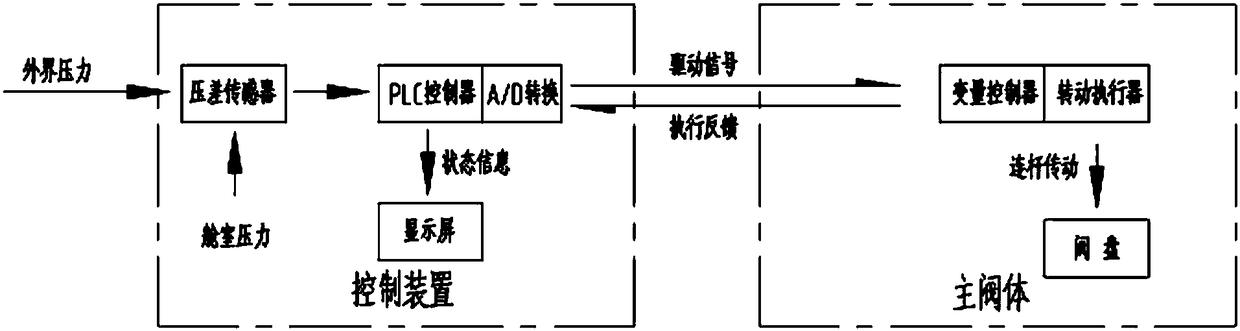

[0023] The following will combine Figure 1 ~ Figure 2 The connecting rod type overpressure control valve and control method of the present invention will be further described in detail.

[0024] The overpressure control valve can maintain a small pressure difference between two spaces or between a space and the outside world, which can prevent mutual cross-contamination.

[0025] figure 1 Shown is a structural schematic diagram of a link type overpressure control valve in a preferred embodiment of the present invention.

[0026] see figure 1 , the link type overpressure control valve includes a protective cover 1 , a main valve body 2 , a link mechanism 3 , a valve disc 4 , an electric actuator 5 and a control device 6 .

[0027] One end of the main valve body 2 is provided with an air inlet 2-1, the other end of the main valve body 2 is provided with an air outlet 2-2, and the protective cover 1 is arranged outside the air outlet 2-2, The protective cover 1 is used to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com