Steam turbine shafting vibration data acquisition, preprocessing and remote sending system

A shafting vibration and data acquisition technology, applied in the general control system, control/regulation system, program control, etc., can solve the problems of not considering data encryption, not applicable to Internet-based remote diagnosis services, data security issues, etc., to achieve Get rid of the mode of local collection and local analysis, avoid network bandwidth bottlenecks, and increase the effect of security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to enable those skilled in the art to better understand the technical solutions in the embodiments of the present invention, and to make the above-mentioned purposes, features and advantages of the present invention more obvious and easy to understand, the technical solutions in the present invention will be further detailed below in conjunction with the accompanying drawings illustrate.

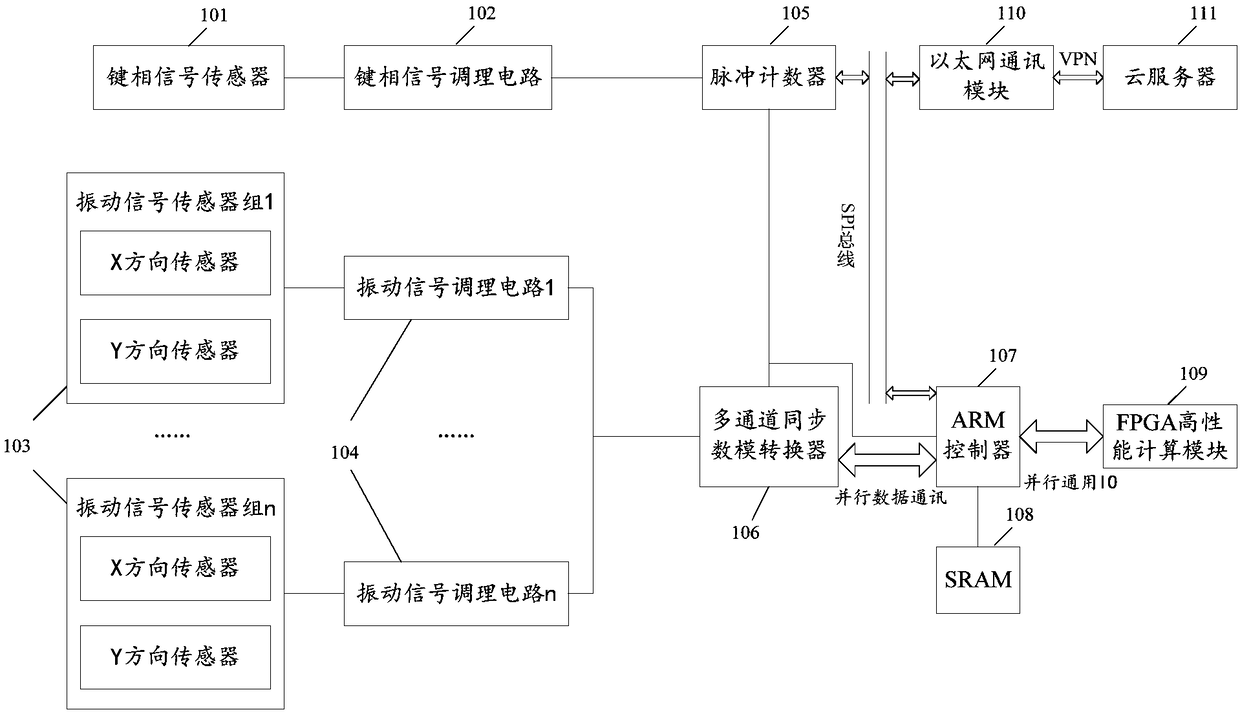

[0054] The present invention proposes a steam turbine shaft vibration data collection, preprocessing and remote transmission system, such as figure 1 As shown, it includes: key phase signal sensor 101, key phase signal conditioning circuit 102, at least one vibration signal sensor group 103, one vibration signal sensor group includes X direction sensor and Y direction sensor, at least one vibration signal conditioning circuit 104, pulse Counter 105, multi-channel synchronous digital-to-analog converter 106, ARM controller 107, SRAM 108, FPGA high-performance computing module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com