An airtight leak detection method for a liquid rocket engine propellant supply pipeline

A technology for supply pipelines and liquid rockets, applied in liquid tightness measurement using liquid/vacuum degree, fluid tightness test, machine/structural component test, etc., can solve long cycle, heavy workload, micro leakage Difficult to check and other problems, to achieve the effect of low cost, rapid response and fast detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Below in conjunction with accompanying drawing and specific embodiment the content of the present invention is described in further detail:

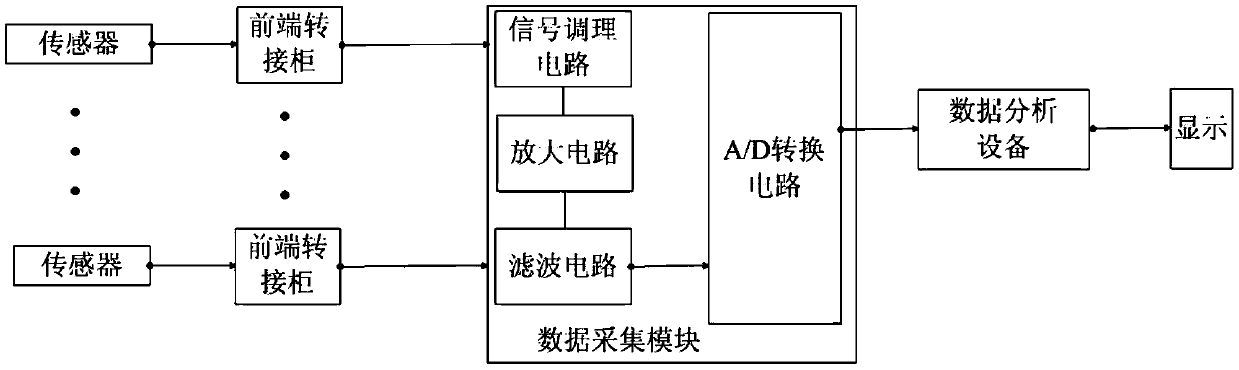

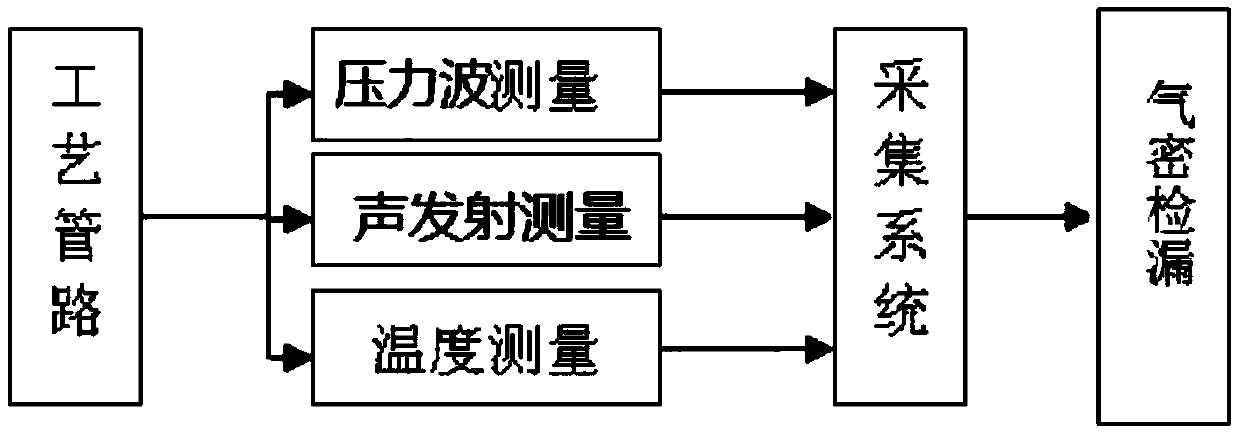

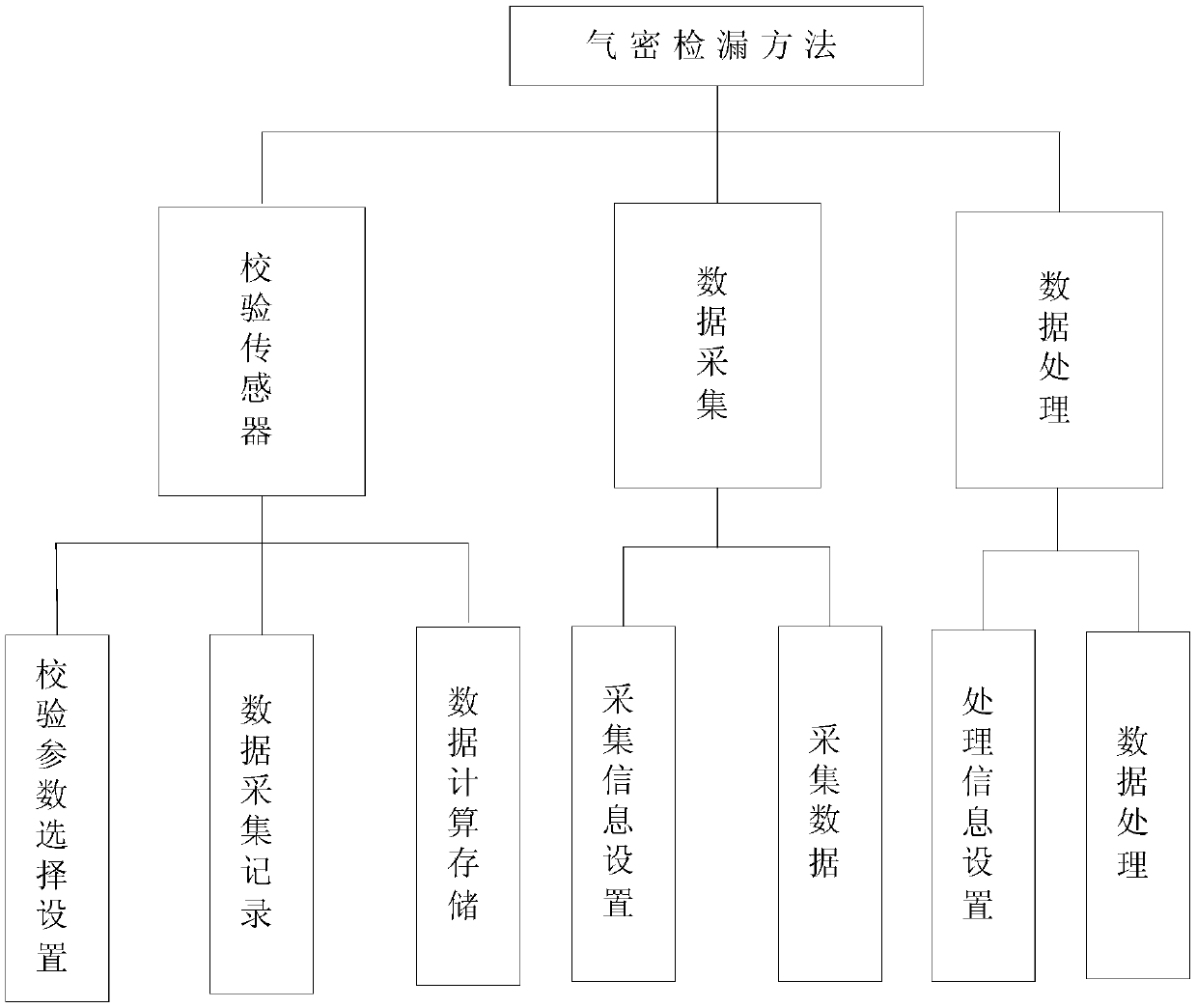

[0058] Such as figure 1 , figure 2 As shown, the liquid rocket engine propellant supply pipeline airtight leak detection system of the present invention includes sensors, front-end adapter cabinets, measurement cables, data acquisition modules, data analysis equipment and displays; wherein the sensors are temperature sensors, pressure sensors and acoustic emission The sensor is mainly used to detect the stress wave and temperature change caused by leakage in the pipeline, and is connected to the front-end transfer cabinet through an active cable; the data acquisition module includes a signal conditioning circuit, an amplification circuit, a filter circuit, and an A / D conversion circuit; data analysis The equipment is a computer, and the computer uses the analysis software containing the leak detection algorithm to analyze the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com