Conductive film layer structure, its manufacturing method and touch screen

A technology of conductive film layer and conductive area, applied in the field of touch display, can solve problems such as adverse effects of touch screen, abnormal size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

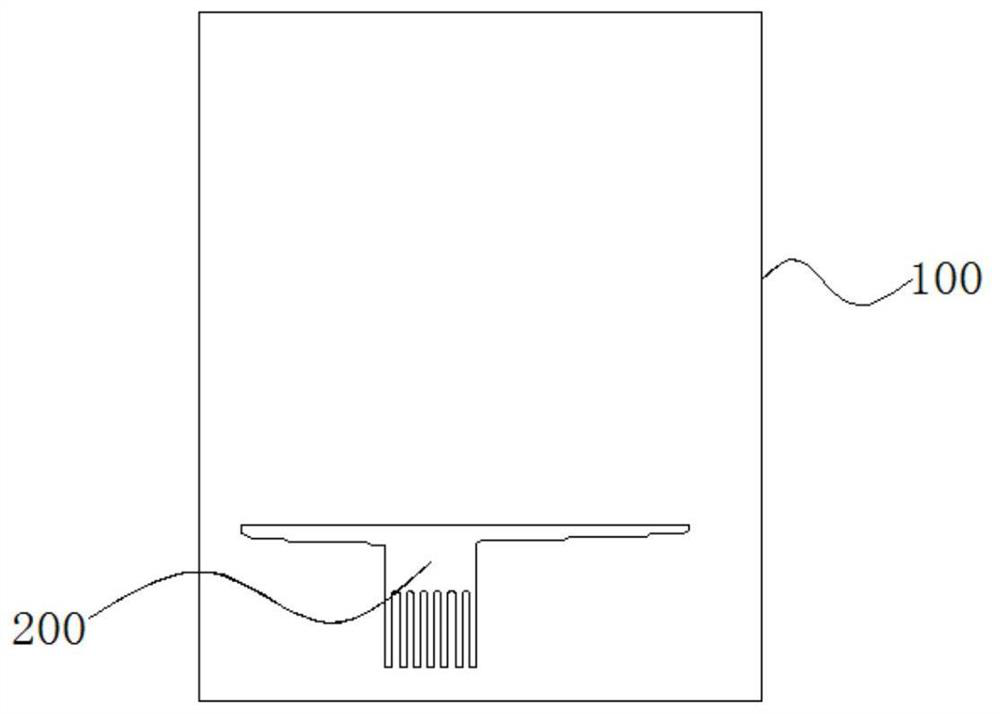

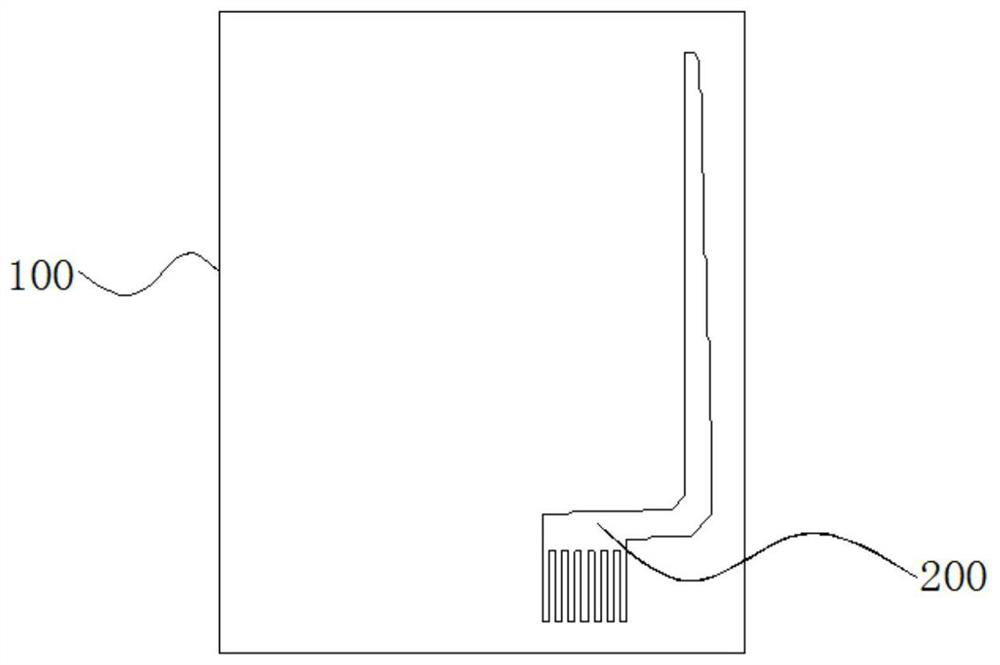

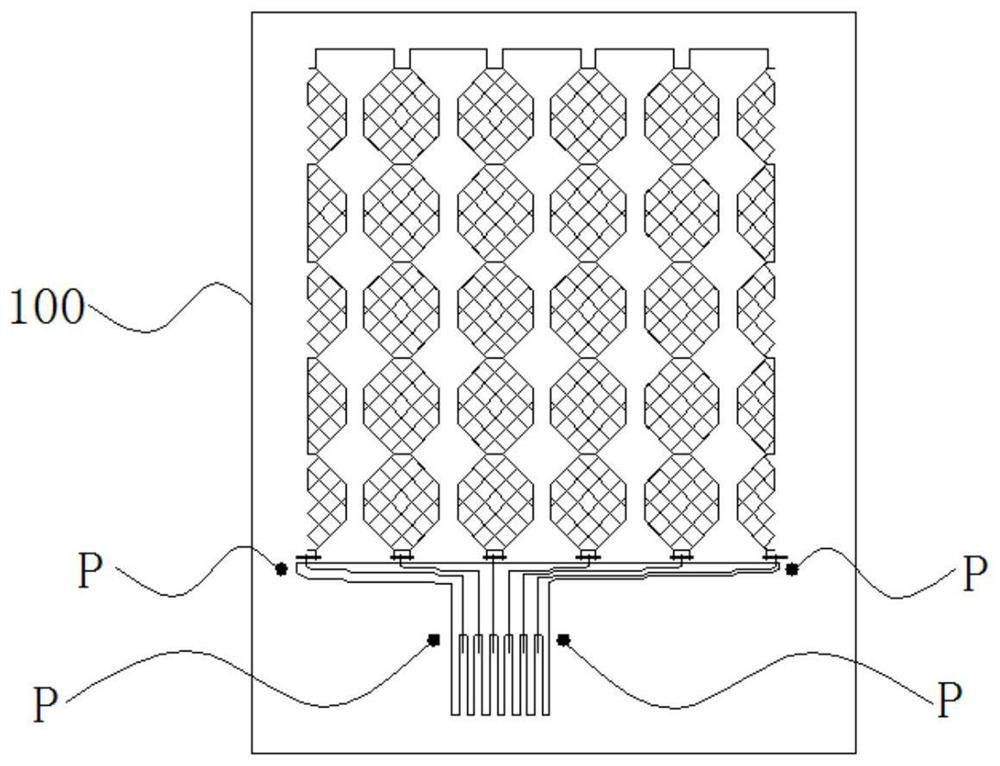

[0048] like Figure 1-4 As shown, the first embodiment provides a conductive film layer structure, including: a conductive film layer 100, the conductive film layer 100 includes a conductive area 200, a sensing area, and a plurality of test blocks for laser line offset adjustment reference A plurality of test blocks are arranged on the outside near the conductive area 200; the test block adopts a structure suitable for the laser line, and the cooperation between the two can facilitate the adjustment of the relative offset between the two.

[0049] In this embodiment, the above-mentioned "conductive material" may use conductive silver paste or be consistent with the material used in the sensing area; when using conductive silver paste, the conductive area 200 may be referred to as a silver paste area.

[0050] In the conductive film layer structure, the conductive film layer 100 is provided with a plurality of test blocks used for laser line offset adjustment references, and th...

Embodiment 2

[0064] The second embodiment provides a method for fabricating the conductive film structure in the first embodiment, including the following steps:

[0065] (A) print conductive area 200 and a plurality of test blocks on the upper or lower film of conductive film layer 100, and print conductive material in conductive area 200;

[0066] (B) Make the laser line hit on a plurality of test blocks, adjust the laser line and align the laser line with each test block;

[0067] (C) Etching the above-mentioned printed conductive material in its entirety.

[0068] It should be noted that, in step (A), the test block and the conductive area 200 are printed at one time by a screen; The position of the block adjusts the offset of the laser relative to the silver paste area as a whole.

[0069] Among them, the method of printing silver paste and laser etching on the upper film is similar to the method of printing silver paste and laser etching on the lower film.

[0070] like image 3 ...

Embodiment 3

[0088] The third embodiment provides a touch screen, including the conductive film layer structure in the first embodiment above.

[0089] Wherein, the conductive film layer structure in the touch screen can be manufactured by the method in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com