Fixing device used for silicon ingot grinding and cutting

A technology for fixing devices and silicon ingots, which is applied to fine working devices, working accessories, stone processing equipment, etc., can solve the problems of slow cutting speed of steel wires, reduce the precision of silicon ingot squares, and the size deviation of crystal bricks, etc., and achieve improvement Cutting speed, improvement of square crystal ingot size deviation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

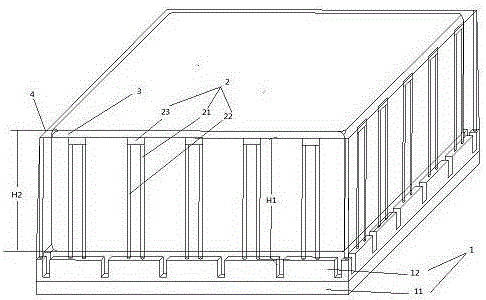

[0011] The present invention will be further described below in conjunction with accompanying drawing.

[0012] As shown in the figure, a fixing device for silicon ingot squaring includes a crystal holder 1, a plurality of baffles 2 are uniformly arranged on the periphery of the crystal holder 1, and the height HI of the baffles 2 is greater than or equal to the The height H2 of the silicon ingot 3, the outer periphery of the baffle plate 2 is covered with a stretched film 4 to form a space for storing cutting fluid with the crystal support 1 as the bottom and the stretched film 4 as the wall; the baffle plate 2 consists of a first branch rod 21, the second rod 22 and the connecting plate 23, the first rod 21 and the second rod 22 are parallel to each other, and the first rod 21 and the second rod 22 are welded or other The first support rod 21 and the second support rod 22 are both perpendicular to the connection rod 23 to form a "door" shaped member. The crystal holder 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com