Polygon coiling needle for lithium coiling machine

A polygonal, needle-rolling technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of poor cell quality consistency, inability to meet production needs, uneven winding speed, etc., to achieve good edge consistency, structure Simple, constant and even winding tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described below.

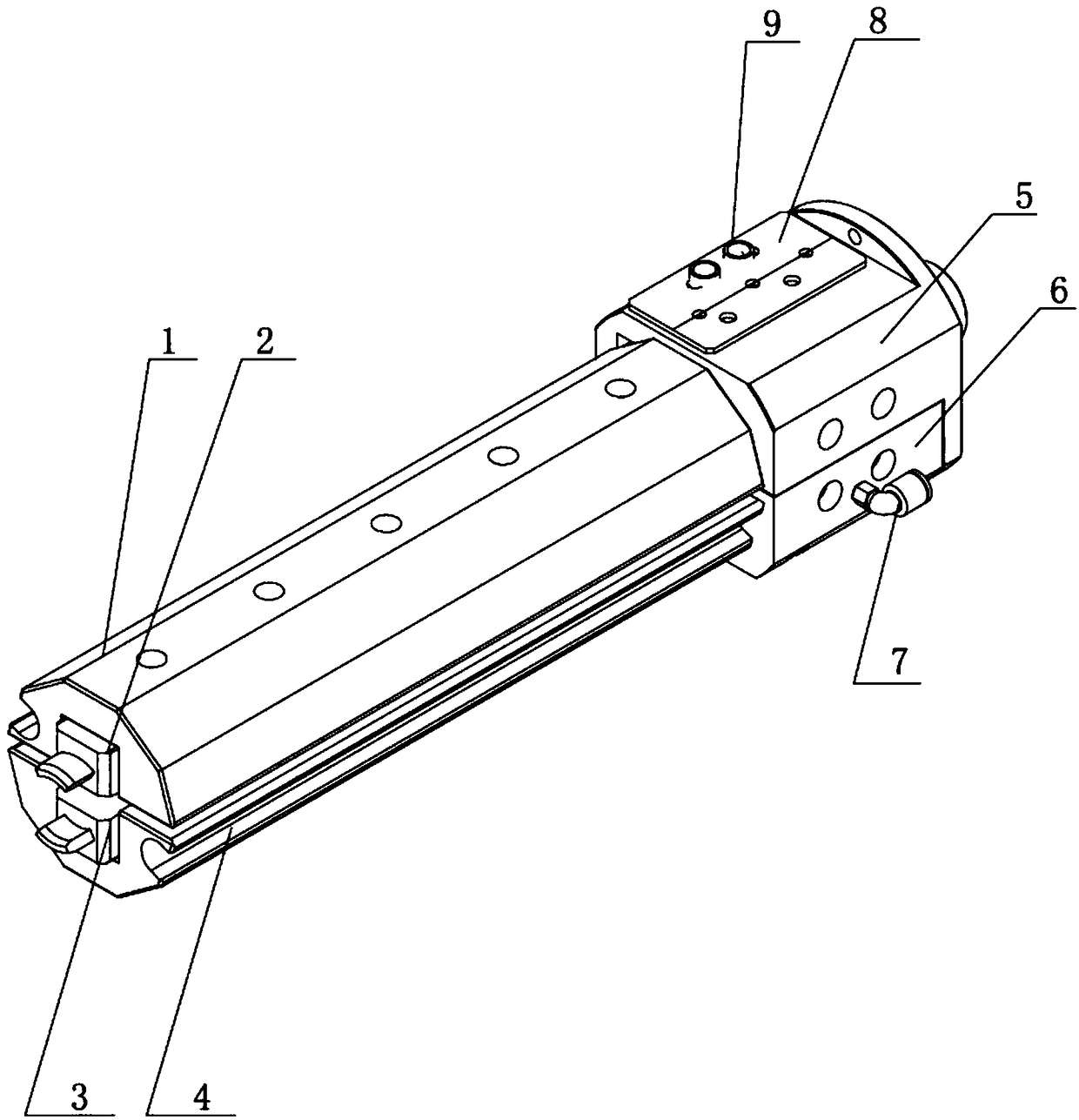

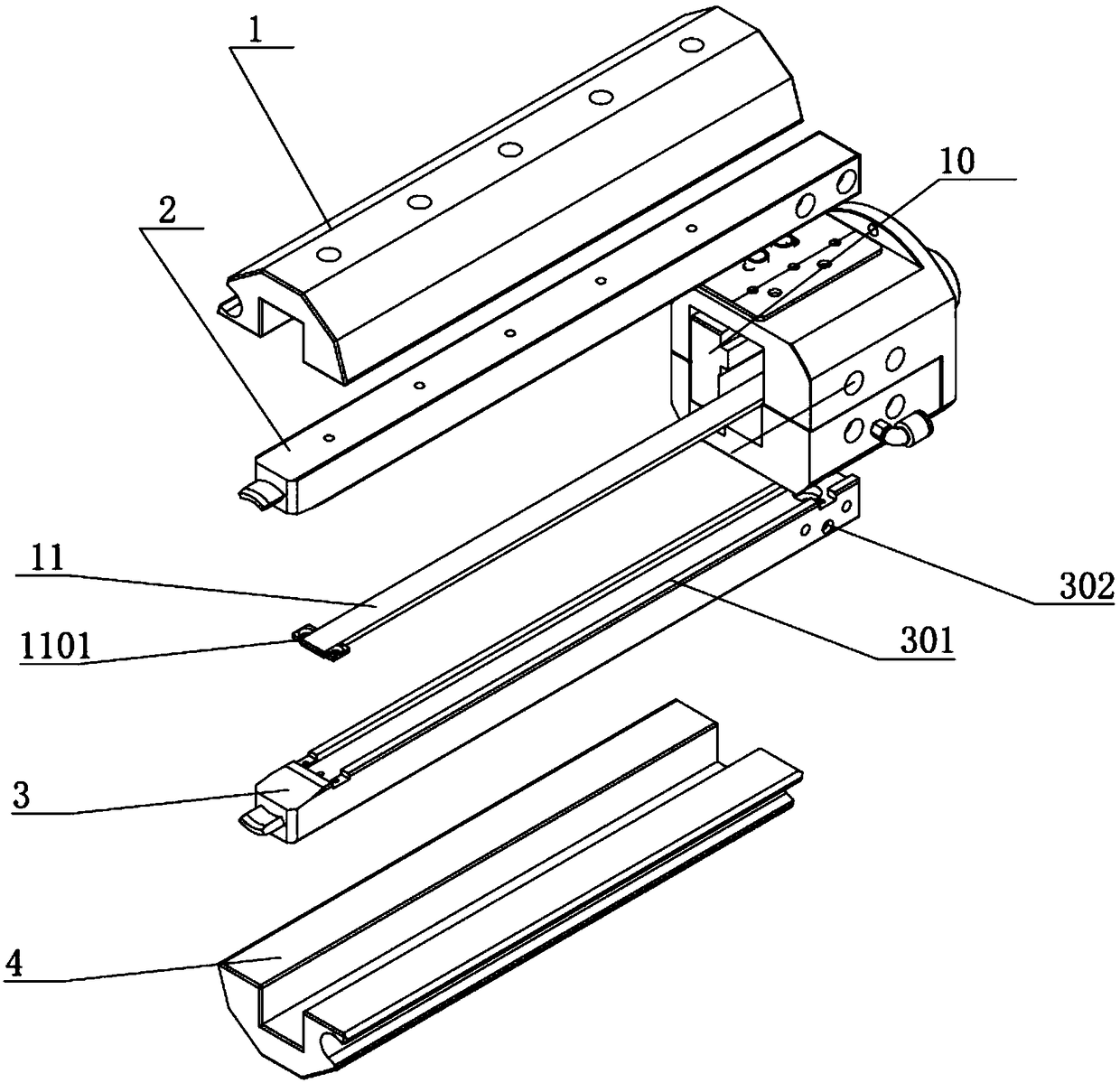

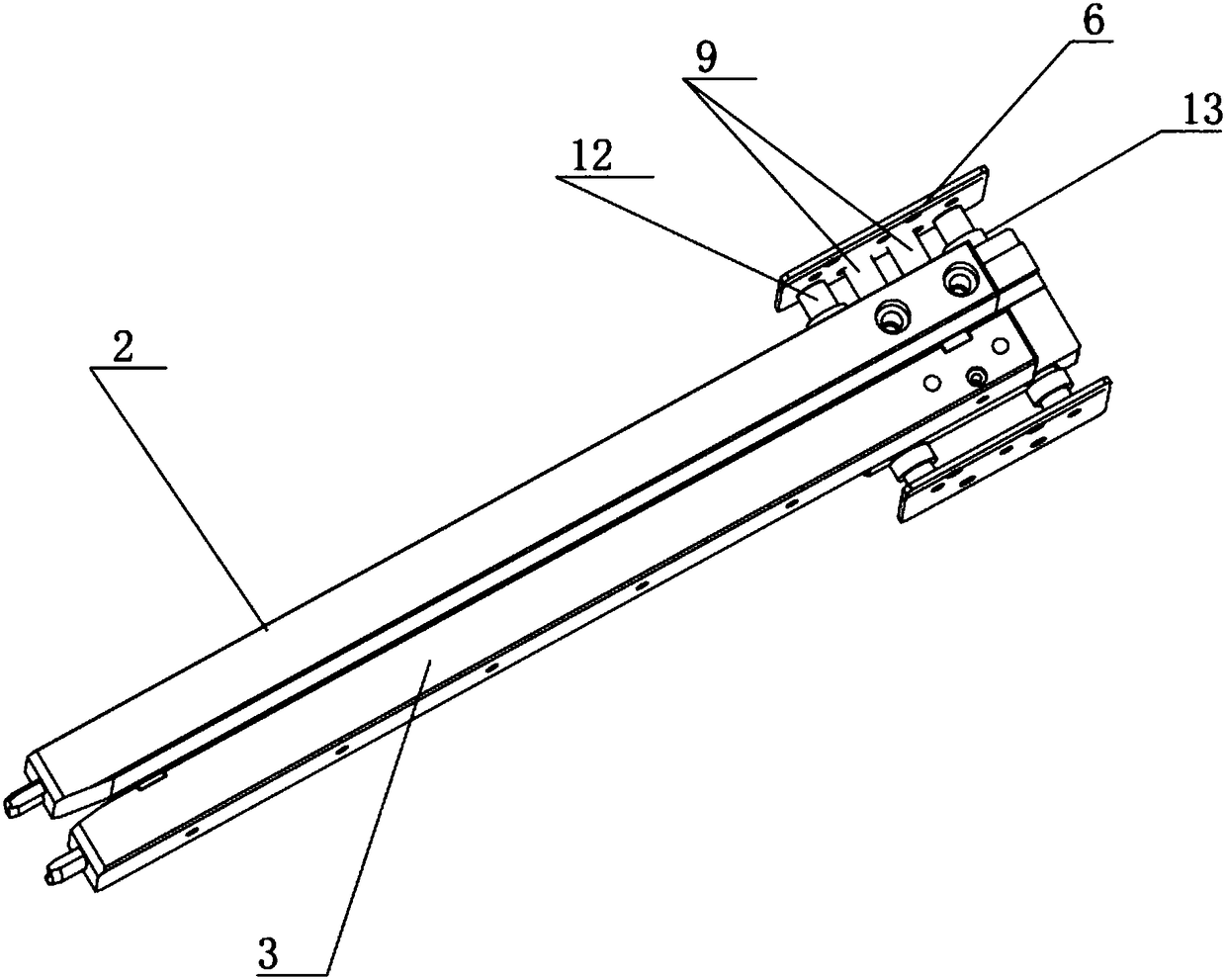

[0017] Such as Figure 1 to Figure 3 As shown, a polygonal winding needle for lithium battery winding stage includes a first winding needle seat 5 and a second winding needle seat 6, a pipe joint 7 is arranged on the second winding needle seat 6, the first winding needle seat 5 and The second needle roll seat 6 is spliced to form a seat body, and an inner cavity is formed inside the seat body, and a slider 10 is arranged in the inner cavity, and the first inner needle 2 is matched on the slider 10. A second inner needle 3 arranged in parallel with the first inner needle 2 is also provided in the cavity, and an airbag installation groove 301 and an air hole 302 communicated with the pipe joint 7 are respectively set on the second inner needle 3, and the airbag installation groove 301 is provided with the airbag installation groove 301. The airbag 11 connected to the air hole 302 is respectively f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com